Separation rotary drum in vacuum pressure swing adsorption separator

A vacuum pressure swing adsorption and separator technology, applied in separation methods, dispersed particle separation, chemical instruments and methods, etc., can solve the problem of high reversing frequency of reversing valves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

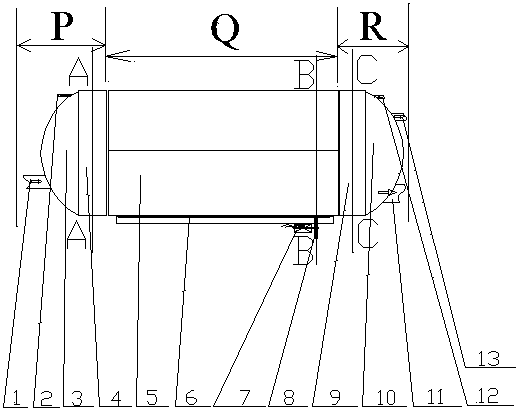

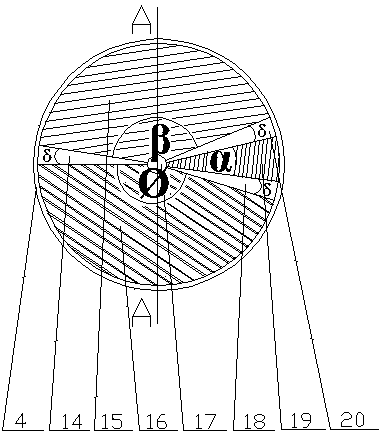

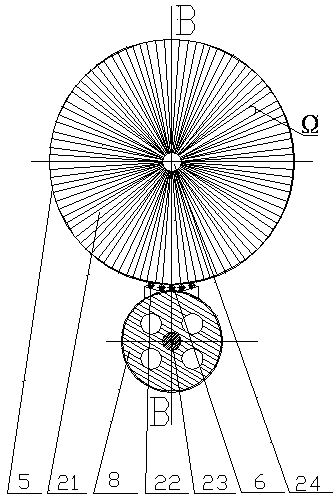

[0018] exist figure 1 In the embodiment shown in —4: the separation drum in the vacuum pressure swing adsorption separator includes the air inlet zone P zone at the left end, the molecular sieve zone Q zone in the middle and the oxygen-enriched collection zone R zone at the right end; it is characterized in that : Air intake area P area includes air inlet pipe 1, back blowing air outlet pipe 2, air intake cover 3 and intake distribution plate 4, the intake distribution plate 4 is divided into air intake sector 16, nitrogen-enriched air extraction corresponding Sector 15, back blowing air outlet fan area 19 and the transition area formed between them, air intake fan area 16 is connected with air inlet pipe 1, but is isolated from other districts, back blowing air outlet fan area 19 and back blowing The gas outlet pipe 2 is connected, but isolated from other areas. The sector 15 corresponding to the nitrogen-enriched air extraction is an independent blind area, which is isolated...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com