The automatic flipping device for integral core trimming of side frame of railway wagon

A technology of automatic flipping and railway wagons, applied in the direction of casting mold, core, casting mold composition, etc., can solve problems such as safety hazards, burrs, flashing, etc., to improve production efficiency and work efficiency, convenient and fast installation and disassembly, and structural design simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

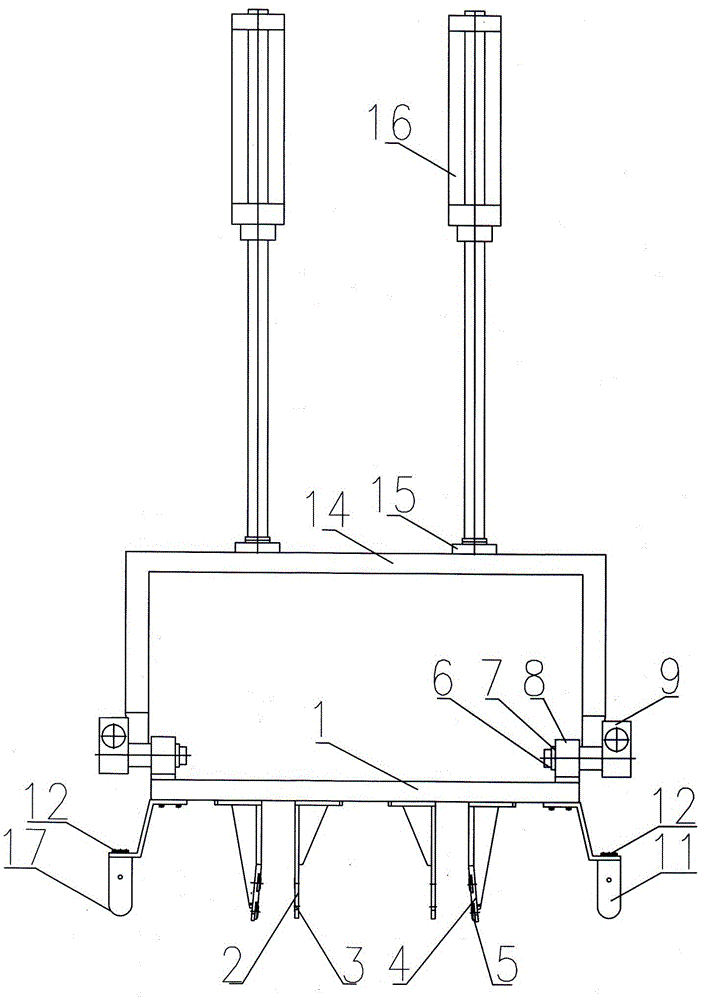

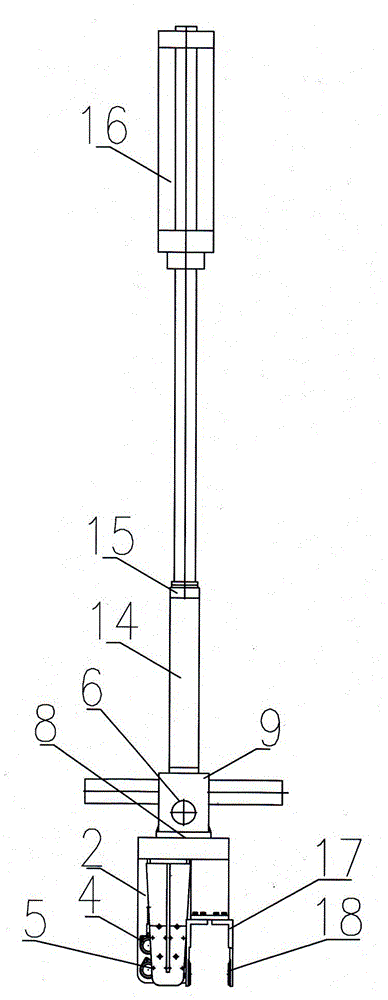

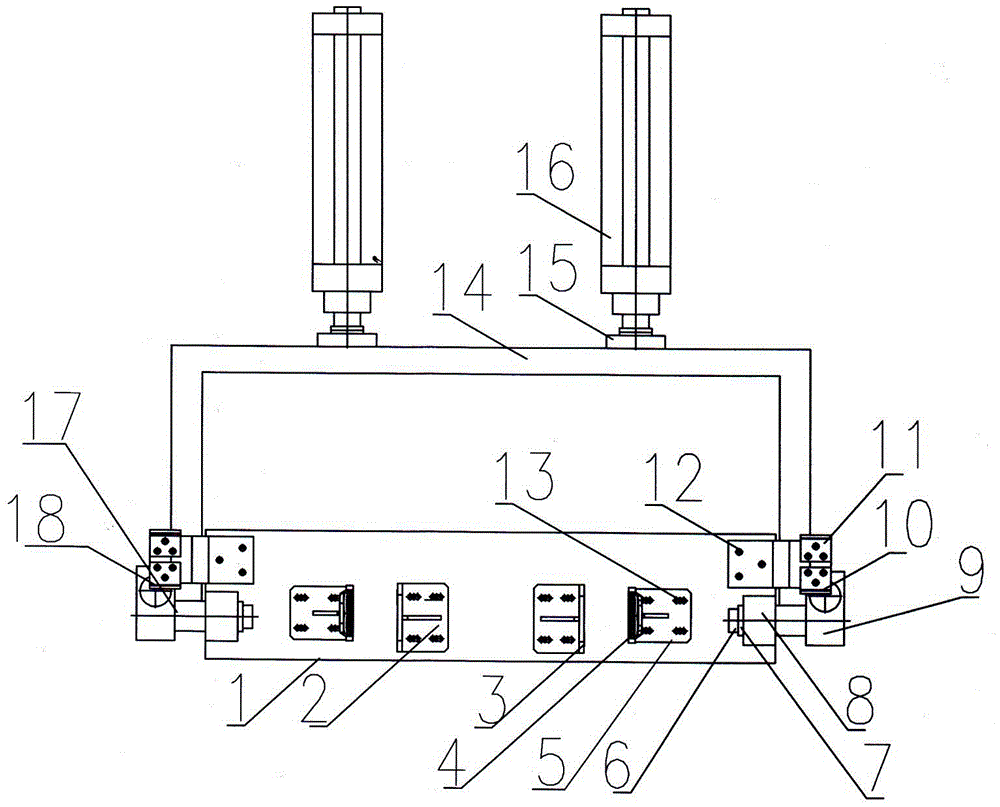

[0016] as attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 The shown one is an automatic turning device used in the foundry industry for the integral core trimming of the railway freight car side frame casting mold.

[0017] The automatic overturning device for the integral core trimming type of the side frame of the railway freight car is characterized in that it includes the overturning pallet 1, the left jaw A 2 of the side frame, and the left jaw A of the side frame is clamped by a diaphragm type cylinder. Module 3, side frame left jaw B 4, side frame left jaw diaphragm cylinder clamping module B 5, turning shaft 6, turning shaft tightening nut 7, turning shaft bracket 8, rack and pinion turning cylinder mechanism 9, Side frame right claw B diaphragm cylinder clamping module 10, side frame right claw B 11, side frame right claw bolt 12, side frame left claw bolt 13, flip frame 14, connecting joint 15, lifting cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com