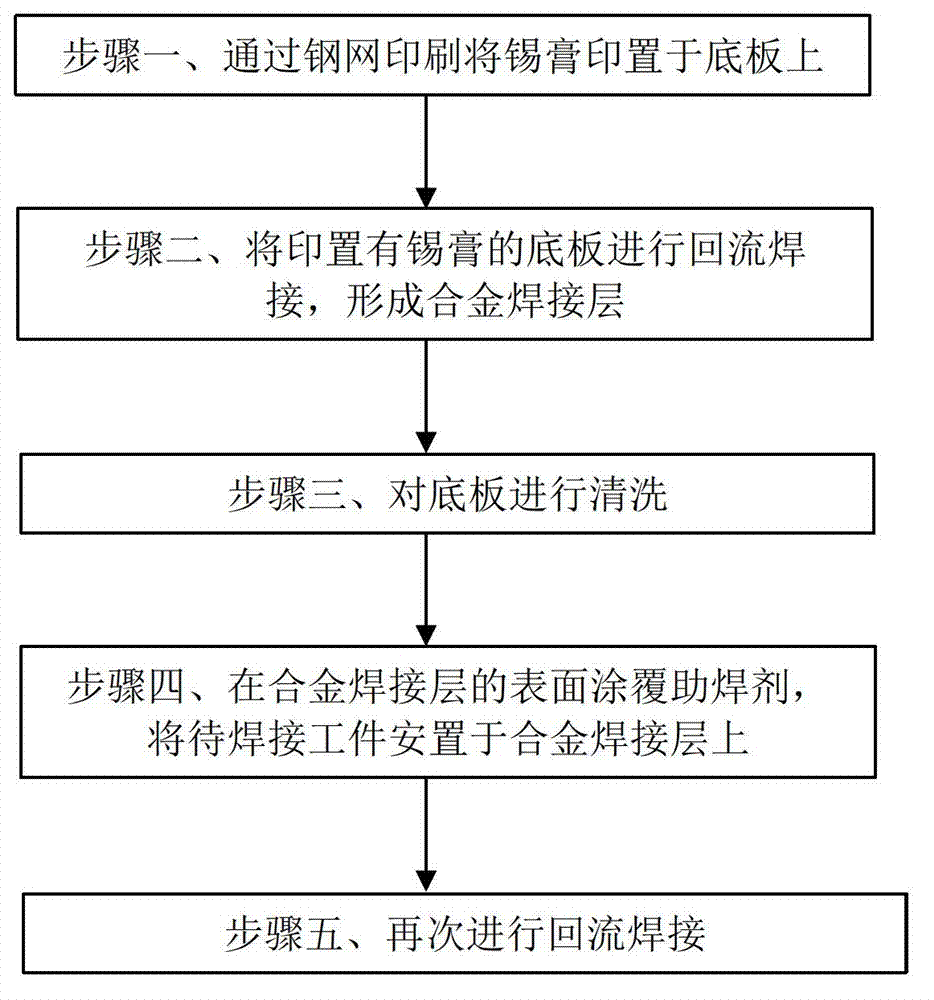

Reflow process welding method

A soldering method and reflow soldering technology, applied in soldering equipment, manufacturing tools, metal processing, etc., can solve problems such as bottom plate pollution, flux overflow, etc., and achieve the effect of solving pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

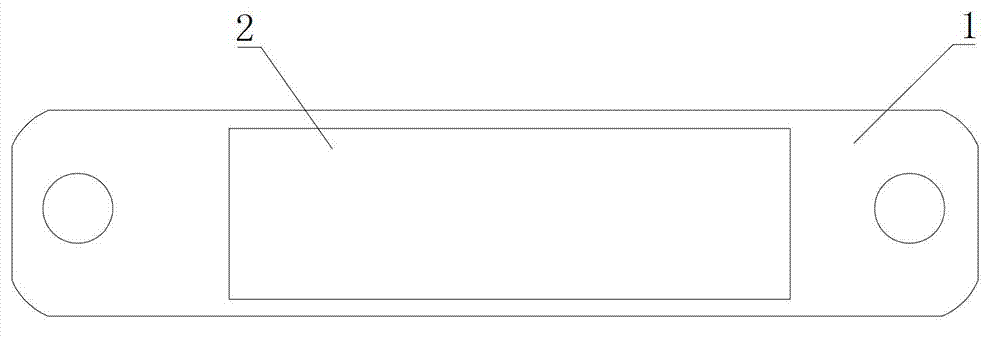

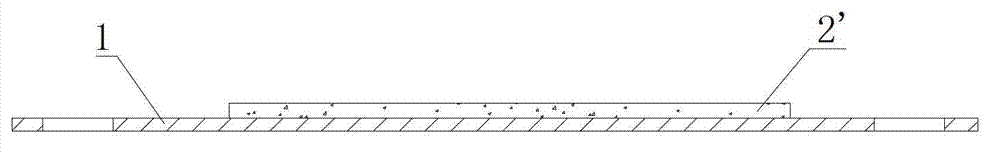

Image

Examples

Embodiment 1

[0027] Direct bonded copper substrate is an electronic basic material made by directly sintering copper foil on the ceramic surface using DBC (Direct Bonded Copper) technology. Because the copper-clad ceramic substrate has excellent thermal cycle performance, stable shape, good rigidity, high thermal conductivity, and high reliability, the copper-clad surface can be etched with various graphics characteristics, and it is a pollution-free and pollution-free It is a green product with a wide range of operating temperatures, from -55°C to 850°C, and its thermal expansion coefficient is close to that of silicon. Its application fields are very wide: it can be used in semiconductor refrigerators, electronic heaters, high-power power semiconductor modules, and power control circuits. , Power hybrid circuits, intelligent power components, high-frequency switching power supplies, solid state relays, automotive electronics, aerospace and military electronic components, solar panel compo...

Embodiment 2

[0036] The difference between this embodiment and embodiment 1 is that in step 4, the coating area of the flux is 90% of the area of the alloy welding layer.

Embodiment 3

[0038] The difference between this embodiment and the preceding embodiments is that the flux used in step 4 is liquid flux. Compared with solid flux, liquid flux has high surface coating efficiency, easy operation, and good uniformity. The proportion is light. During the reflow soldering process, the liquid flux will appear in gaseous form, so there will be no flux residue, and the effect is better. The liquid flux used in this embodiment is the flux of NCX-FS manufactured by ALPHA Company.

[0039]It can be seen from the above technical scheme that the method of the present invention uses two reflow soldering methods to solder the components. When performing the first reflow soldering in step 2, the reflow soldering temperature is set at the reference temperature N°C (that is, the solder paste used Since the reflow soldering temperature is not set high, the flux in the solder paste has not been subjected to high temperature when cleaning after the reflow soldering, and the o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com