Welding missing control device and welding missing control method for butt welding seams of guide pipes in complicated spatial orientation

A technology of butt welding seam and control device, which is applied in pipeline systems, manufacturing tools, welding equipment, etc., to achieve good processing technology, economy, and compact structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0025] The present invention provides a control device for butt weld leakage control of conduits with complex directions in space. The conduits with complex directions in space refer to conduits with multiple curved sections. Seam weld leakage refers to the back reinforcement of the butt weld.

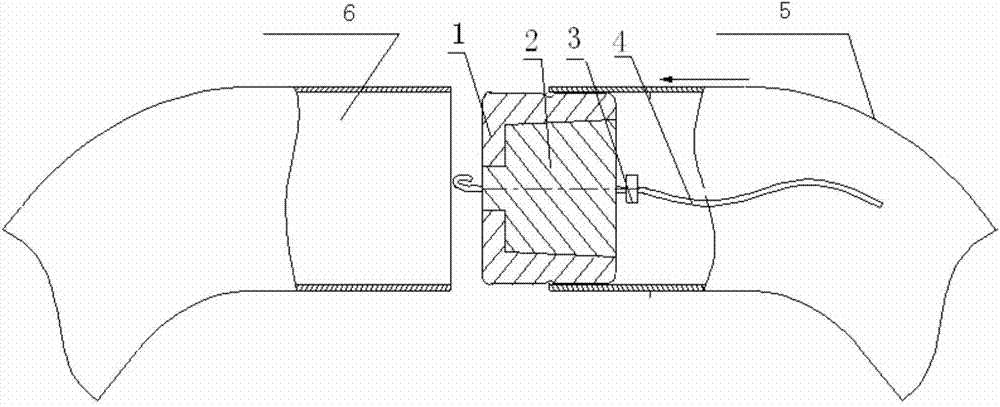

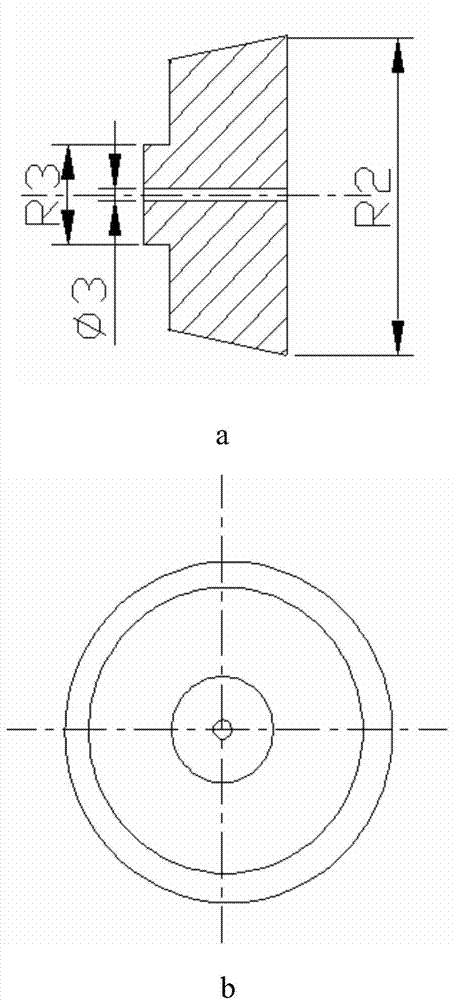

[0026] Such as figure 1 As shown, a leakage control device for butt welds of conduits with complex directions in space provided by the present invention includes: expansion block 1, wedge-shaped shaft 2, stop block 3 and steel wire rope 4;

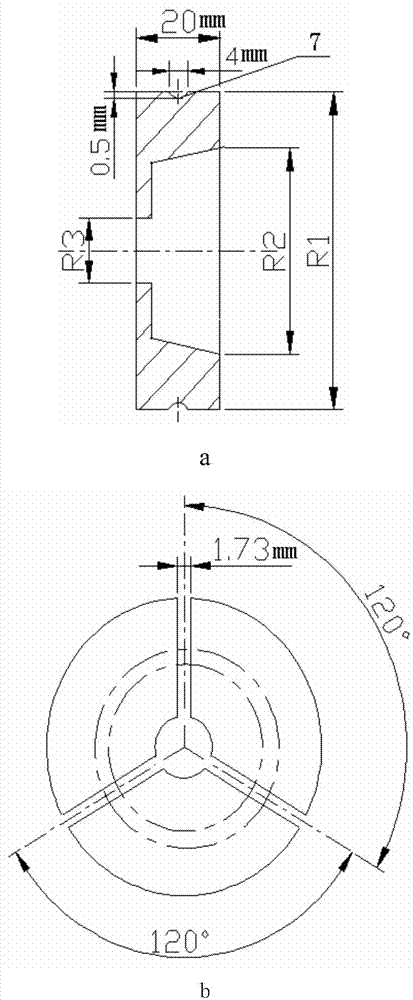

[0027] Such as figure 2 As shown, the number of the expansion blocks 1 is three, and the arc-shaped contours of the outer arc surfaces of the three expansion blocks 1 form a circle, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com