Reflection type monitoring device for laser micro processing process

A monitoring device and micro-machining technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems that the changes of key micro-nano structures cannot be significantly prompted, the monitoring system is complicated, and the monitoring cost is expensive, and the structure is achieved. Simple, small amount of collected data, and fast collection speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

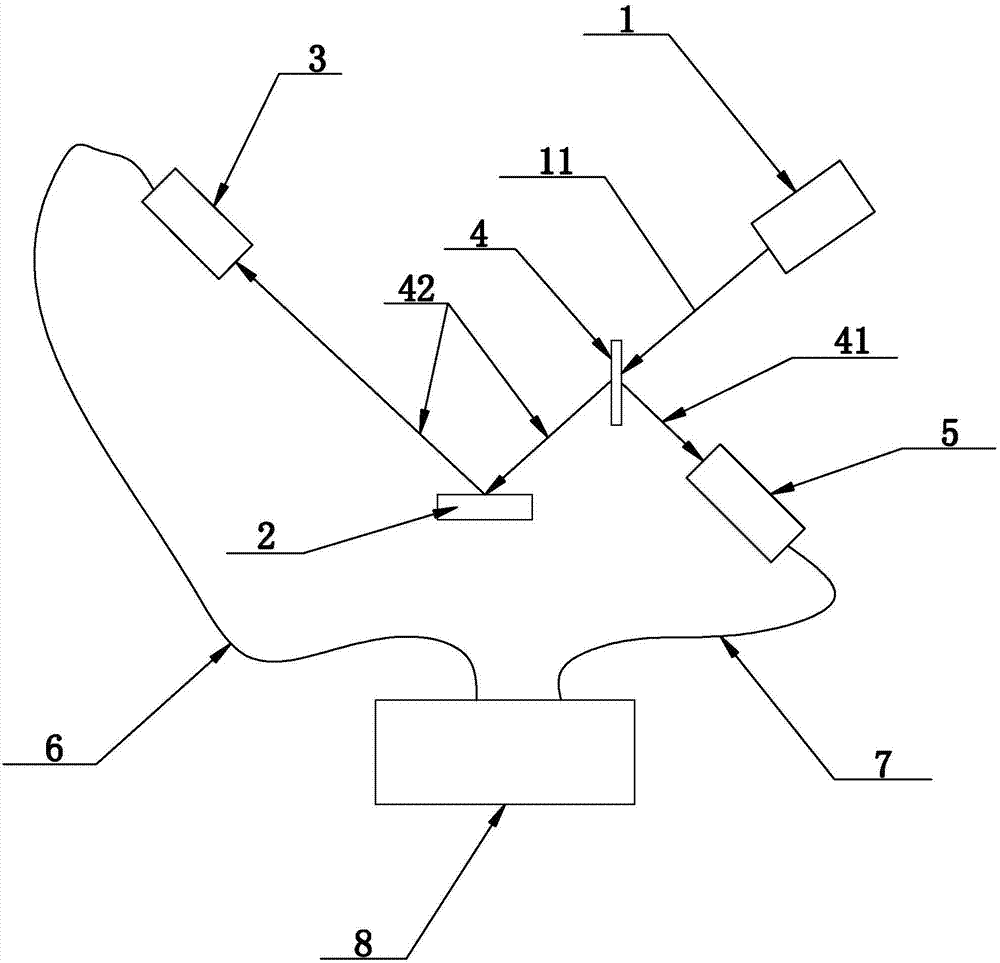

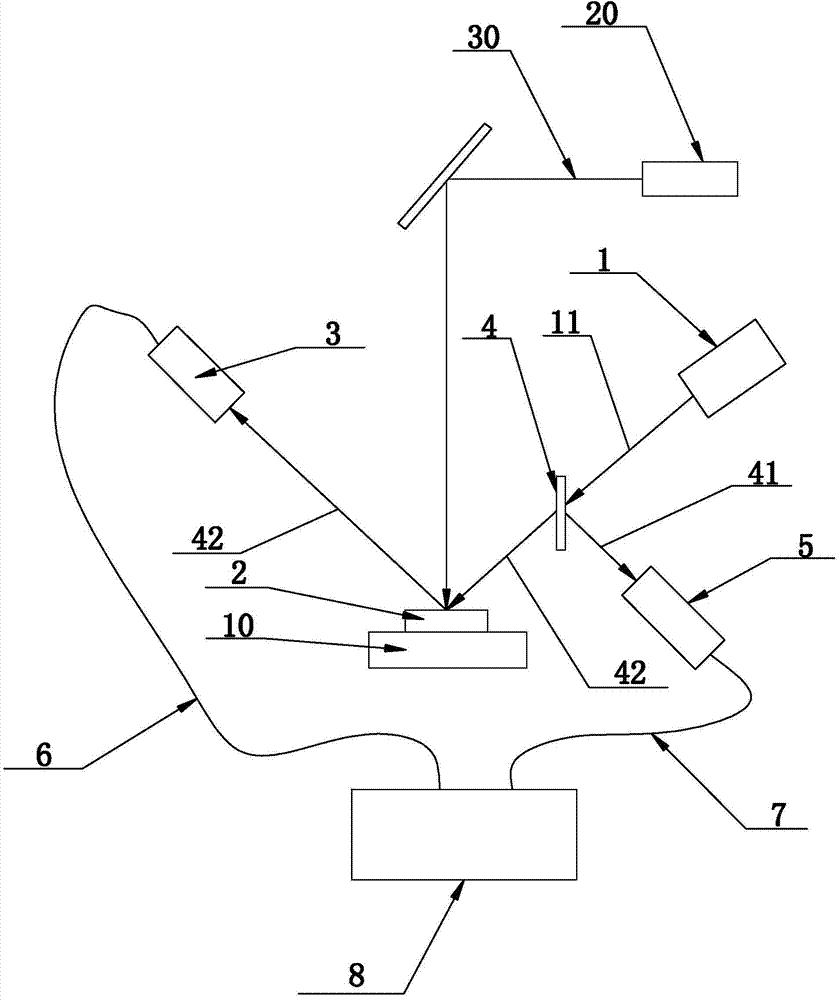

[0014] see figure 1 , a reflective monitoring device for a laser micromachining process disclosed by the present invention, comprising a helium-neon laser 1, a detection laser beam 11 emitted from the front end of the helium-neon laser 1 is provided with a workpiece 2 on the emission line, and the workpiece 2 A first photoelectric probe 3 is arranged on the reflection line of the detection laser beam 11, and a laser beam splitter 4 is arranged in the middle of the emission line of the detection laser beam 11 at the front end of the helium-neon laser 1, through which the detection laser beam 11 is specifically It is divided into a reference signal 41 and a reflected light signal 42. The reflected light signal 42 enters the first photoelectric probe 3 after being reflected by the workpiece 2. The front end of the reference light signal 41 is provided with a second photoelectric probe 5, and the reference light signal 41 directly enters the first photoelectric probe 3. Two photoe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com