A method of making enlarged seal rubbings

A seal and printing paper technology, which is applied in the field of making enlarged seal rubbings, can solve problems such as defect font size of text patterns, adverse effects of artistic effects of craft products, and uneven arrangement, so as to ensure accuracy, integrity and uniform coloring Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with accompanying drawing:

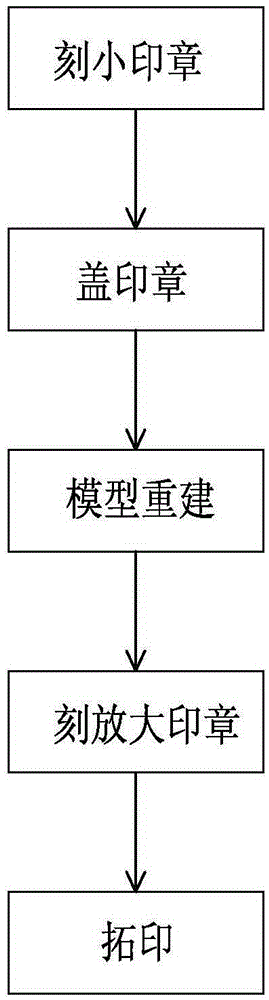

[0021] A method for making enlarged seal rubbings, comprising the steps of:

[0022] (1) Engraving a small seal: engraving reverse text patterns on the body of the small seal;

[0023] (2) Stamp: Stamp the stamp with the reverse character pattern on the paper to stamp the positive character pattern;

[0024] (3) Model reconstruction: scan the text pattern on the paper in step (2) with a laser copying machine to obtain the contour data of the text pattern, and reconstruct the model with the contour data and reverse engineering software to generate a CNC machining program; The said reverse engineering software is UG.

[0025] (4) Engraving enlarged seals: implant the CNC machining program obtained in step (3) into a computer engraving machine, and use the computer engraving machine to engrave enlarged positive text patterns on the large stamp body according to the required ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com