Rear Suspension of Hydraulic Interconnected Torsion Elimination Suspension

A hydraulic and torsion suspension technology, applied in the suspension, interconnection system, transportation and packaging, etc., can solve the problems of severe torsional load, poor oil coupling and high cost of the car body, and achieve the elimination of torsional load of the car body and enhanced acceleration performance, the effect of improving grounding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with accompanying drawing and embodiment.

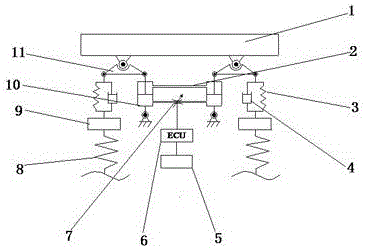

[0011] Such as figure 1 As shown, the rear suspension of the present invention includes a sprung mass 1 and a group of hydraulically interconnected torsion-removing components, which are respectively located at the bottom ends of both sides of the sprung mass 1. Spring 3, shock absorber 4, double-acting hydraulic cylinder 10, unobstructed pipeline 2, electronic control unit 6 and display screen 5; wherein, isosceles triangle with vertex angle greater than 120° for isosceles lever 11, unobstructed pipeline 2 is High-pressure pipeline.

[0012] The apex of the upper end of the equal arm lever 11 is hinged with the bottom ends on both sides of the sprung mass 1, and the upper end of the parallel body of the spring 3 and the shock absorber 4 and the upper end of the double-acting hydraulic cylinder 10 are respectively connected to the upper end of the equal arm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com