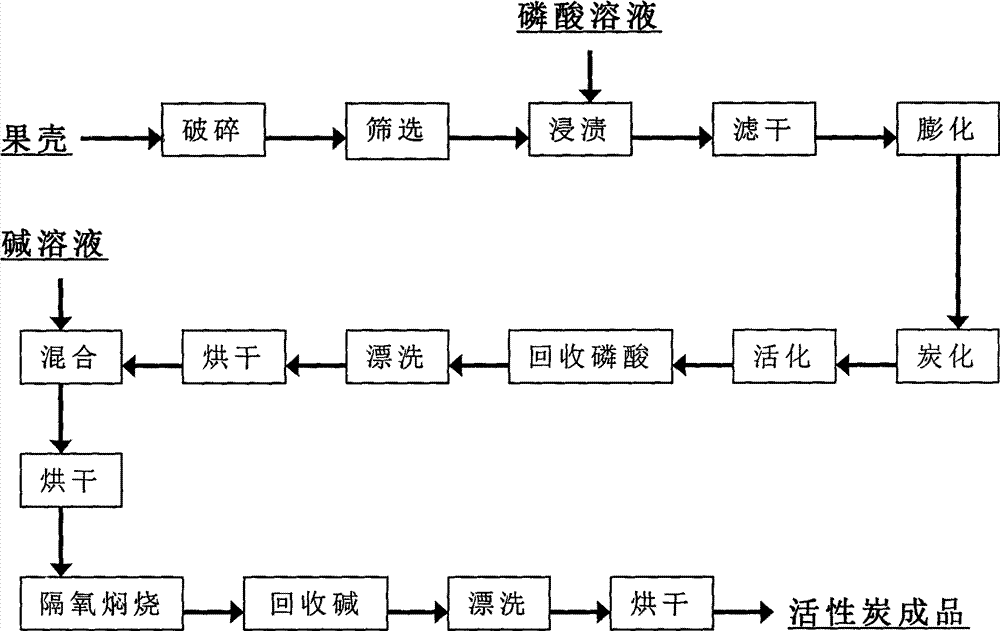

Method and equipment for preparing activated carbon carrier for storing natural gas from hard husks

A technology of natural gas and hard nutshells, applied in chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of reducing the adsorption capacity of finished activated carbon, and achieve easy recycling, large specific surface area, good swelling and expansion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

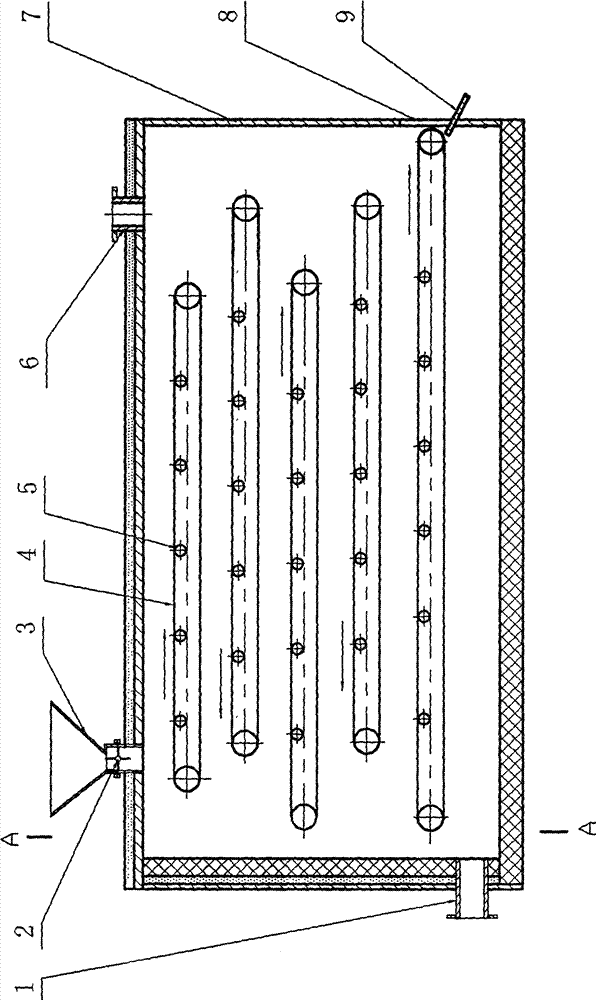

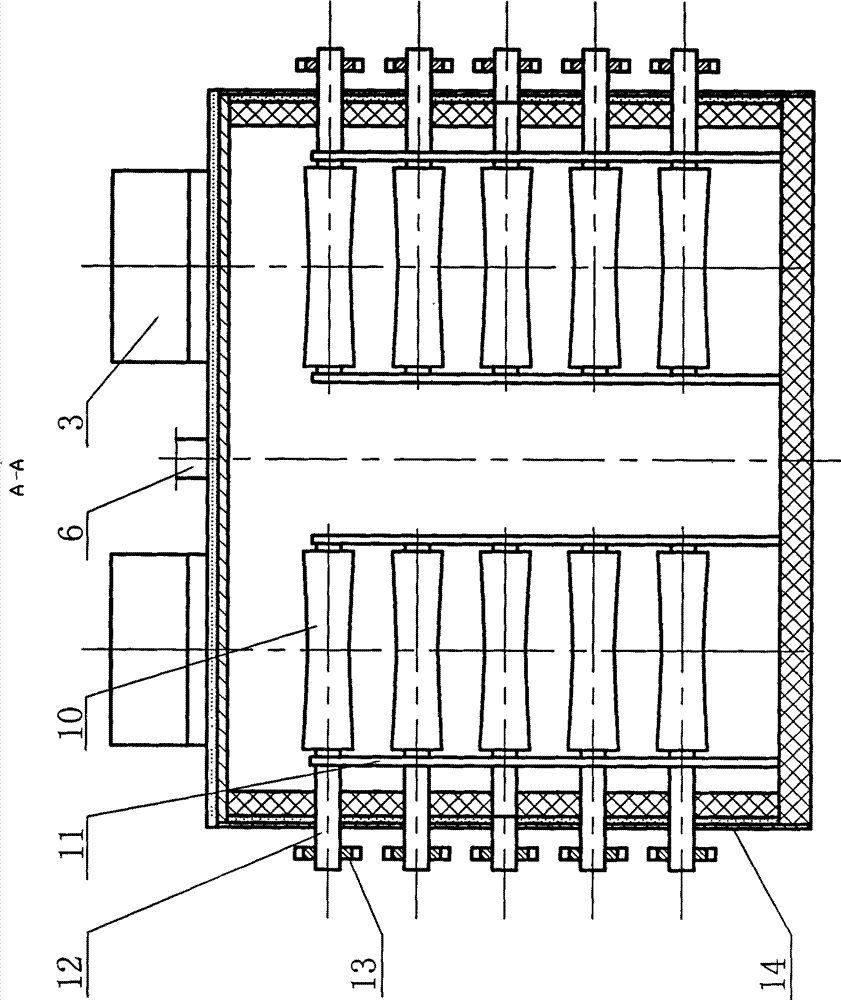

[0016]Crush the raw material of the fruit shell to 10-20 meshes, soak it with 85% phosphoric acid solution at 90-100°C for 1 hour, then filter it dry and use a three-dimensional plasticizing equipment to expand and expand at a temperature of 120-130°C to adjust the conveyor belt. The running speed is 1.5 m / min. The conveyor belt of the plasticizing equipment is 40 meters long, and there are 5 layers of conveyor belts. The plasticized shell material is output from the discharge port (8), and the residence time of the shell material in the plasticizing equipment is about For 133 minutes, the shell material was expanded and the inside of the particles became looser, and then the expanded material was added Figure 4 In the vertical charcoal activation furnace shown, carbonization and activation are carried out at a temperature of 250-480°C, the activation material is released at an appropriate discharge speed, and then the activation material is soaked in hot water for 7 times, ea...

example 2

[0019] Crush the raw material of fruit shells to 10-20 meshes, dip in 75% phosphoric acid solution at 90-100°C for 1 hour, then filter dry and use plasticizing equipment to expand and expand at a temperature of 120-130°C to adjust the running speed of the conveyor belt The conveyor belt of the plasticizing equipment is 40 meters long, and there are 5 layers of conveyor belts. The plasticized shell material is output from the discharge port (8), and the residence time of the shell material in the plasticizing equipment is about 133 Minutes, so that the shell material is puffed and the inside of the granule becomes looser, and then the puffed material is added Figure 4 In the vertical charcoal activation furnace shown, carbonization and activation are carried out at a temperature of 250-480°C, and the activation material is discharged at an appropriate discharge speed, and then the activation material is soaked in hot water for 7 times, each time for 15 minutes, and recovered T...

example 3

[0022] Crush the raw material of the fruit shell to 5-10 meshes, soak in boiling water for 4 hours, then filter and dry until the water content is 20-30%, soak in 85% phosphoric acid solution at 90-100°C for 1 hour, then filter and dry with plastic The plasticizing equipment is swollen and puffed at a temperature of 120-130°C, and the running speed of the conveyor belt is adjusted to 1.5 m / min. The conveyor belt of the plasticizing equipment is 40 meters long, with a total of 5 layers of conveyor belts. Port (8) output, the residence time of the shell material in the plasticizing equipment is about 133 minutes, so that the shell material is expanded and the inside of the particle becomes looser, and then the expanded material is added Figure 4 In the vertical charcoal activation furnace shown, carbonization and activation are carried out at a temperature of 250-480°C, and the activation material is discharged at an appropriate discharge speed, and then the activation material ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com