Industrial extracting method for ampelopsin

A technology of staphylophyllin and purification method, which is applied in the direction of organic chemistry, can solve the problems of high water viscosity, weak penetrating power, and low efficiency of water extraction process, and achieve the effect of improving work efficiency and extract yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

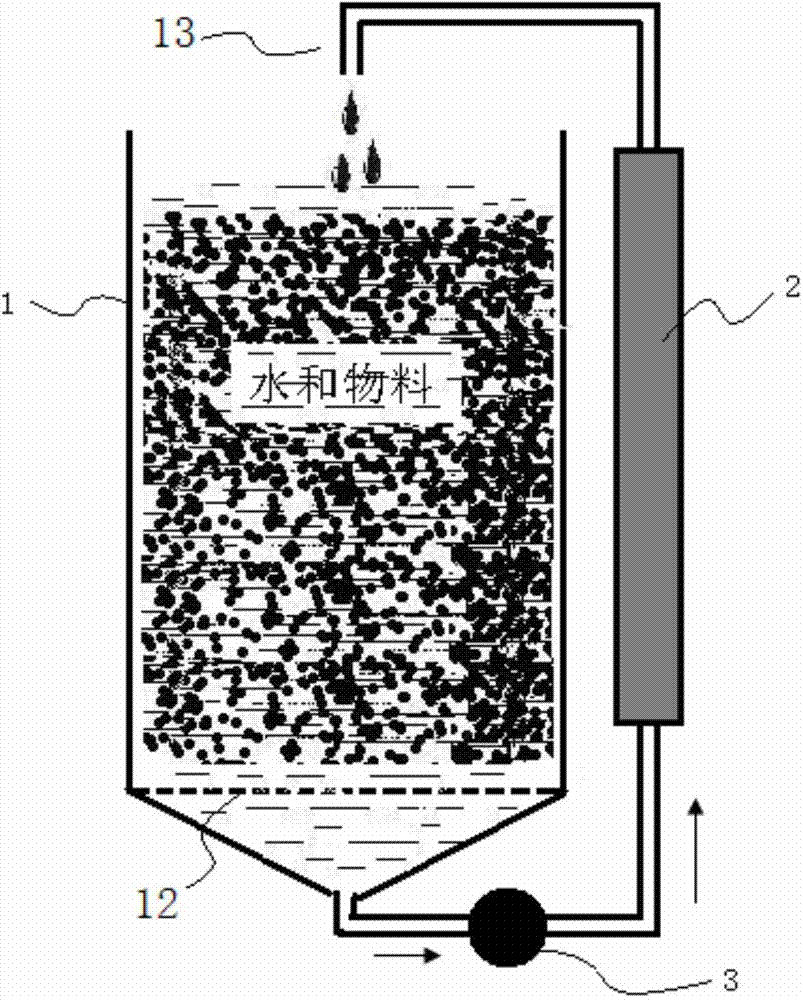

[0030] The extraction tank 1 has a water circulation pump 3 with two-way circulation function and a magnetizer 2 on the water circulation pipeline. The method of use is: after adding materials, inject pure water through the nozzle 13, and then turn on the reverse circulation pump 3 to start heating cycle extraction ; The bottom of the extraction tank 1 is provided with a filter plate 12 . The bottom of the extraction tank 1 sequentially passes through the circulation pump 3 and the magnetizer 2 to extract and magnetize the liquid at the bottom of the extraction tank 1 to the top of the extraction tank 1 .

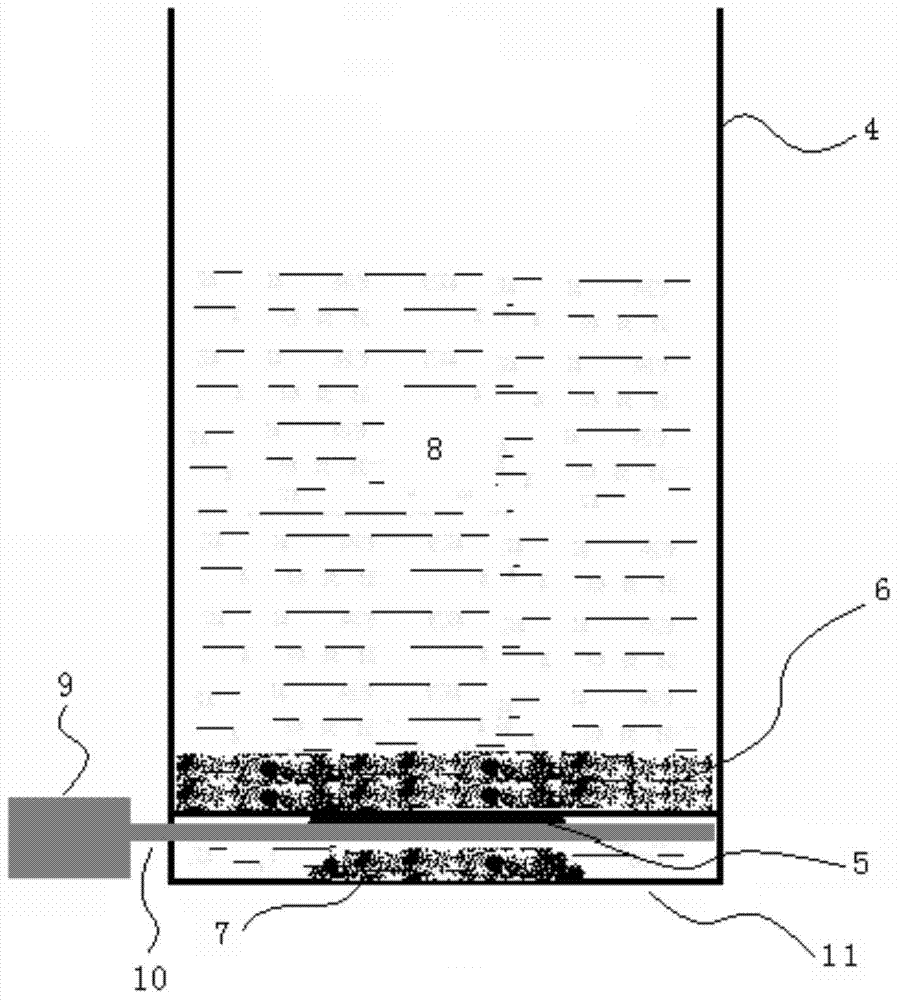

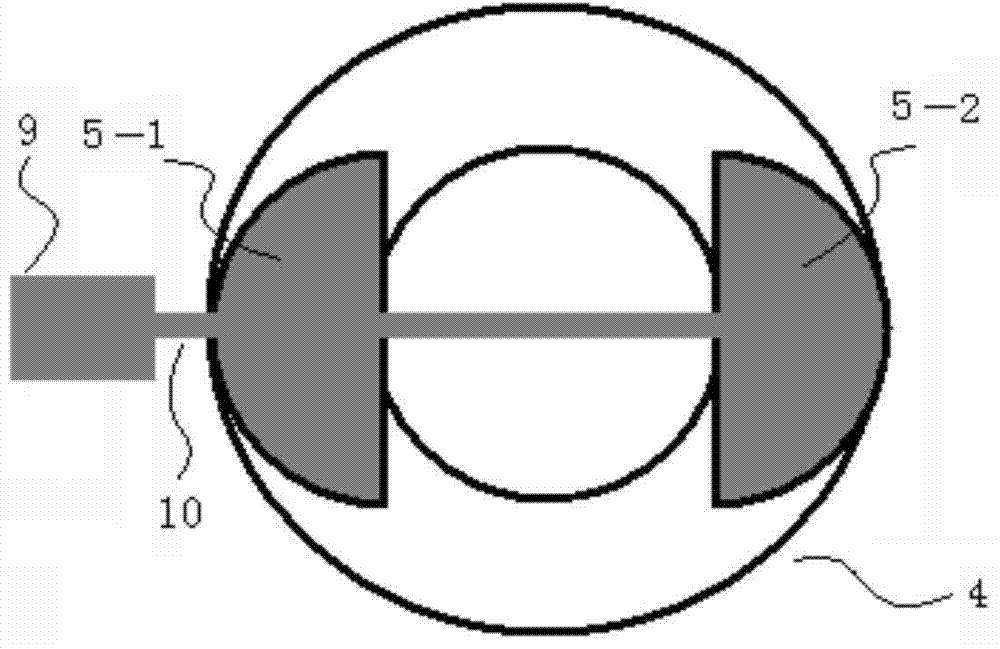

[0031] The center of the bottom of the sedimentation tank 4 is provided with a polyphenol sedimentation tank 11 whose height is one-twentieth to one-fifteenth of the height of the sedimentation tank. The top of the polyphenol sedimentation tank also has a bottom seal 5, which is Two semicircular fan blades (5-1, 5-2) are composed and automatically open and play the role of ...

Embodiment 2

[0047] The extraction tank 1 has a water circulation pump 3 with two-way circulation function and a magnetizer 2 on the water circulation pipeline. The method of use is: after adding materials, inject pure water through the nozzle 13, and then turn on the reverse circulation pump 3 to start heating cycle extraction ; The bottom of the extraction tank 1 is provided with a filter plate 12 . The bottom of the extraction tank 1 sequentially passes through the circulation pump 3 and the magnetizer 2 to extract and magnetize the liquid at the bottom of the extraction tank 1 to the top of the extraction tank 1 .

[0048] The center of the bottom of the sedimentation tank 4 is provided with a polyphenol sedimentation tank 11 whose height is one-twentieth to one-fifteenth of the height of the sedimentation tank. The top of the polyphenol sedimentation tank also has a bottom seal 5, which is Two semicircular fan blades (5-1, 5-2) are composed and automatically open and play the role of ...

Embodiment 3

[0063] The extraction tank 1 has a water circulation pump 3 with two-way circulation function and a magnetizer 2 on the water circulation pipeline. The method of use is: after adding materials, inject pure water through the nozzle 13, and then turn on the reverse circulation pump 3 to start heating cycle extraction ; The bottom of the extraction tank 1 is provided with a filter plate 12 . The bottom of the extraction tank 1 sequentially passes through the circulation pump 3 and the magnetizer 2 to extract and magnetize the liquid at the bottom of the extraction tank 1 to the top of the extraction tank 1 .

[0064] The center of the bottom of the sedimentation tank 4 is provided with a polyphenol sedimentation tank 11 whose height is one-twentieth to one-fifteenth of the height of the sedimentation tank. The top of the polyphenol sedimentation tank also has a bottom seal 5, which is Two semicircular fan blades (5-1, 5-2) are composed and automatically open and play the role of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com