Asphalt regenerant that can be recycled multiple times and its preparation method and application process

A kind of asphalt regenerant and multiple regeneration technology, which is applied in the direction of building components, building insulation materials, buildings, etc., can solve the problems of negative impact on road performance, waste of natural resources, and reduction of economic benefits, so as to achieve rich sources of raw materials and realize Simple method and good regenerative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

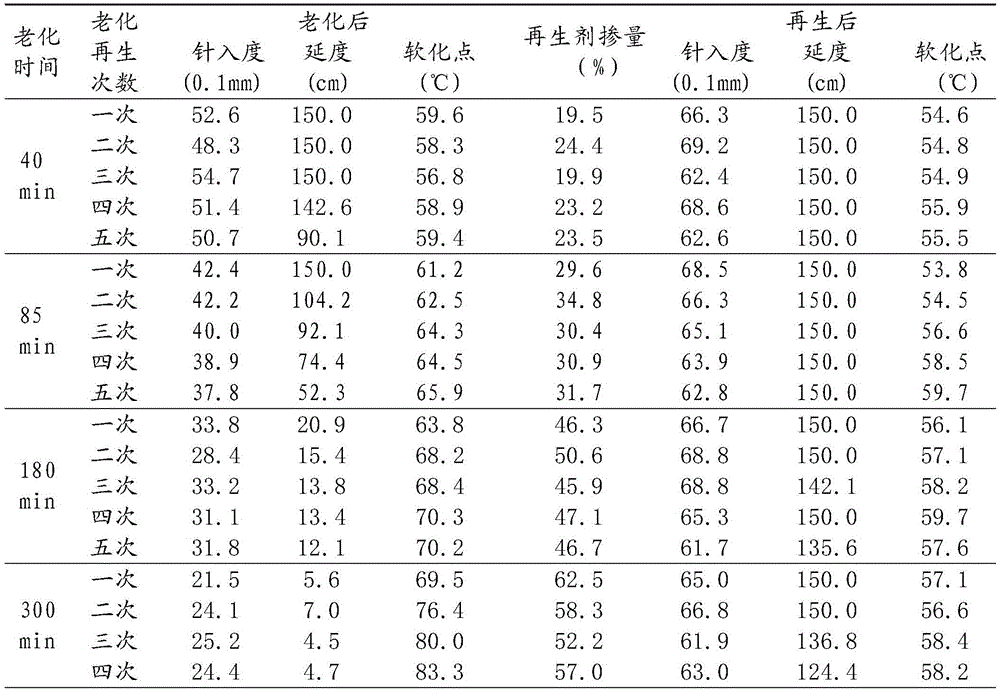

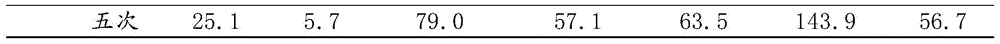

Image

Examples

Embodiment

[0017] Raw materials: 2.8g of epoxy resin, 4.0g of waste engine oil, and 81.1g of No. 90 asphalt.

[0018] (1) Put No. 90 asphalt in a film oven at 110°C for 1.5 hours at a constant temperature;

[0019] (2), 2.8g epoxy resin and 4.0g waste engine oil are mixed and heated and stirred evenly, so that the temperature of the mixture of epoxy resin and waste engine oil reaches 140°C to 160°C;

[0020] (3) When the temperature of the mixture of epoxy resin and waste engine oil reaches 140°C to 160°C, add 81.1g of No. 90 asphalt prepared therein, continue to heat on low heat and stir continuously, so that it is fully mixed until it becomes liquid. It can be made by regenerating agent many times.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com