Millet wine production and fermentation device and production technology thereof

A fermentation device and production process technology, applied in the field of food fermentation devices, can solve the problems of too long production time and insufficient improvement of production equipment, etc., and achieve the effects of less equipment, shortened rice soaking time, and low labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make it easier for those skilled in the art to understand and implement the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

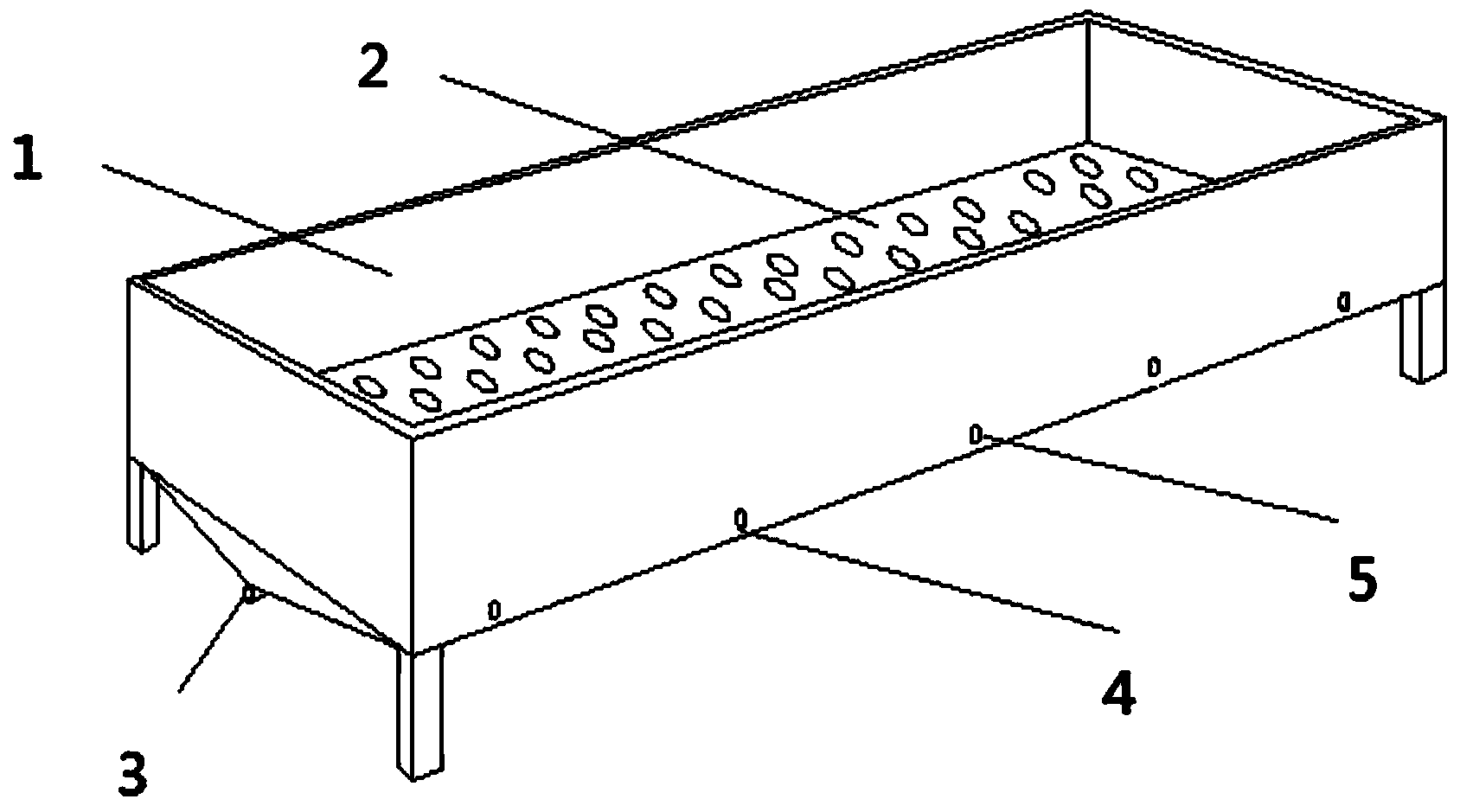

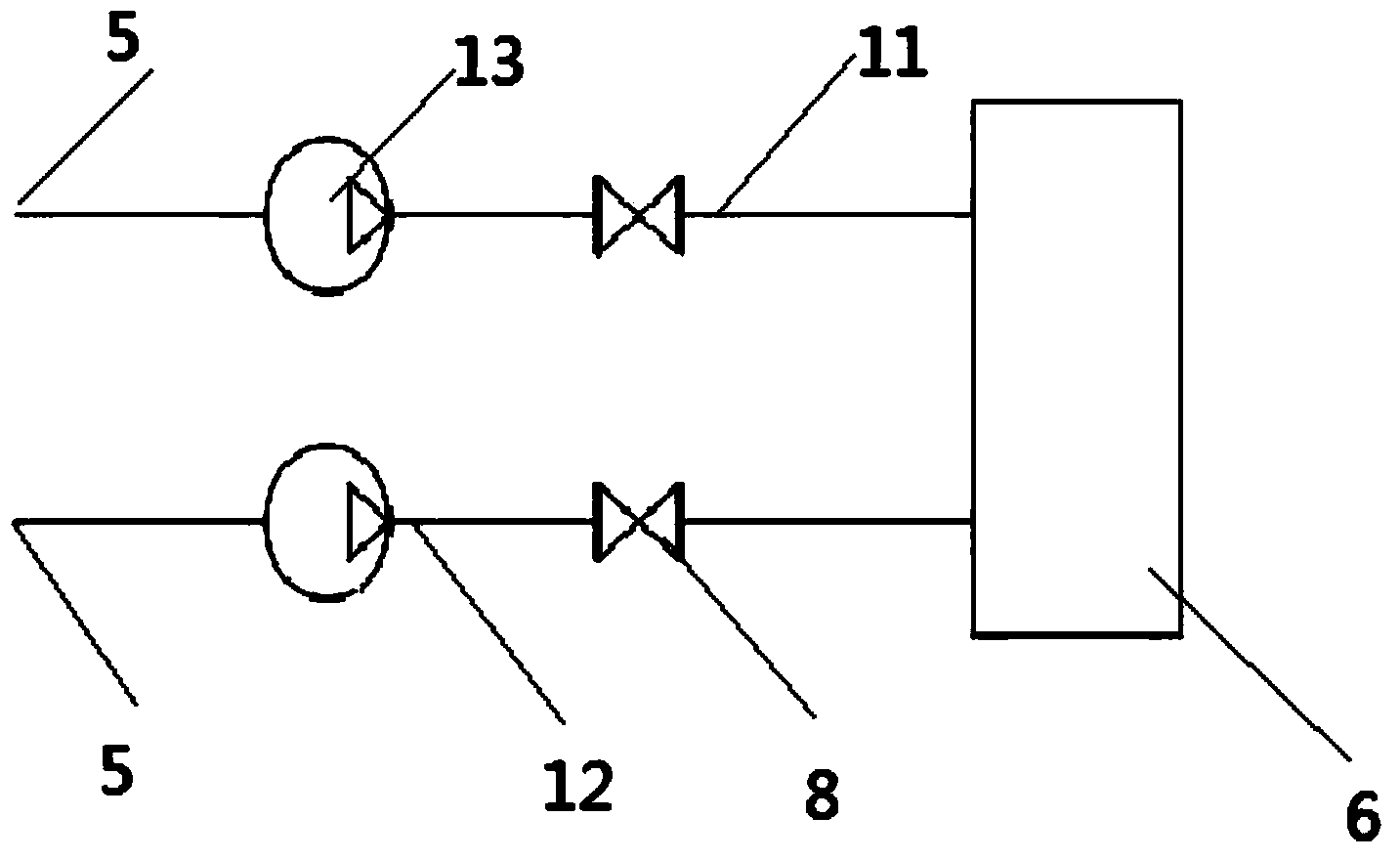

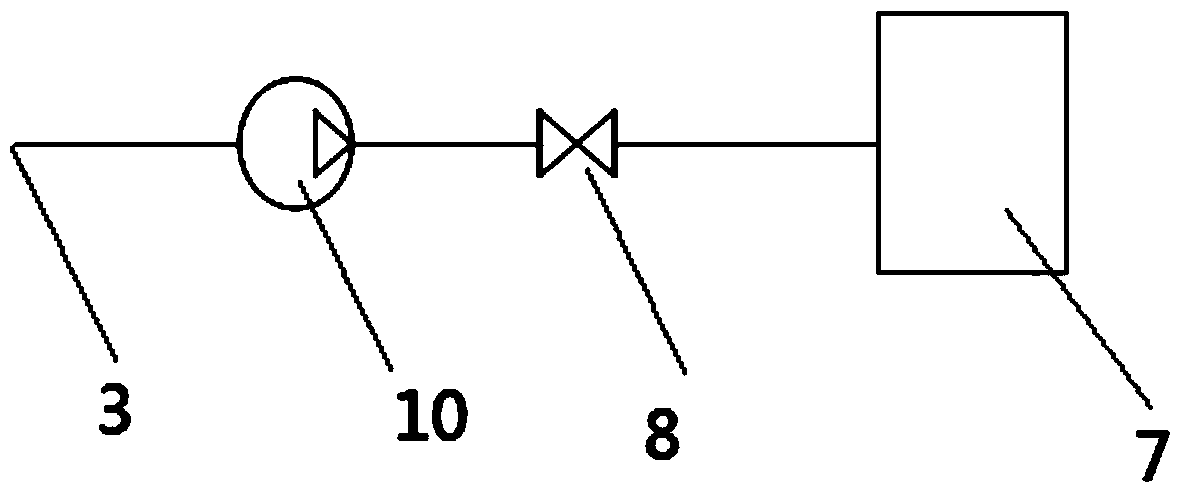

[0038] Such as figure 1 Shown, be that a specification is: 800x244x122 (mm), use the yellow rice wine fermenting vat 1 of an upper opening of stainless steel material to make, set up one deck mesh sieve plate 2 with the mesh of stainless steel making at 50mm place on its bottom, and An interlayer is formed at the bottom of the fermentation tank, and the interlayer is equipped with an air blowing device. The whole mesh screen plate can be removed from the bottom of the fermentation tank with a hook. The bottom is provided with a discharge hole 3, and the lower part of the side wall is provided with a ventilation hole 4 and a water inlet and outlet hole. 5. It can input or discharge clean water and rice milk water, as well as steam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com