Country prefabricated steel structure residence system and construction method thereof

A steel structure and assembly technology, applied in the direction of residential buildings, building structures, columns, etc., can solve the problems of unguaranteed seismic performance, long construction period, and damage to farmland, so as to avoid local buckling damage and facilitate construction Fast, good force and deformation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

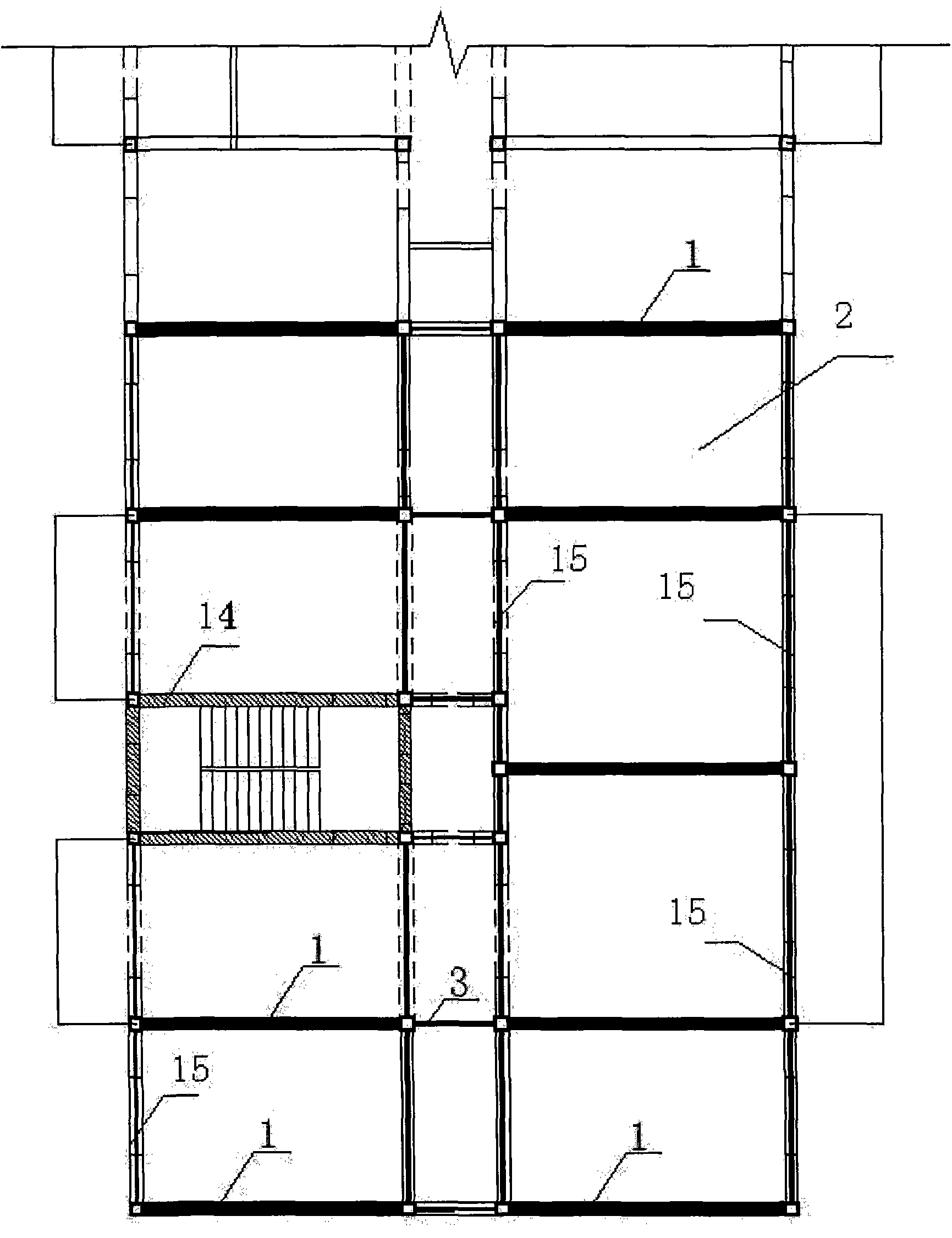

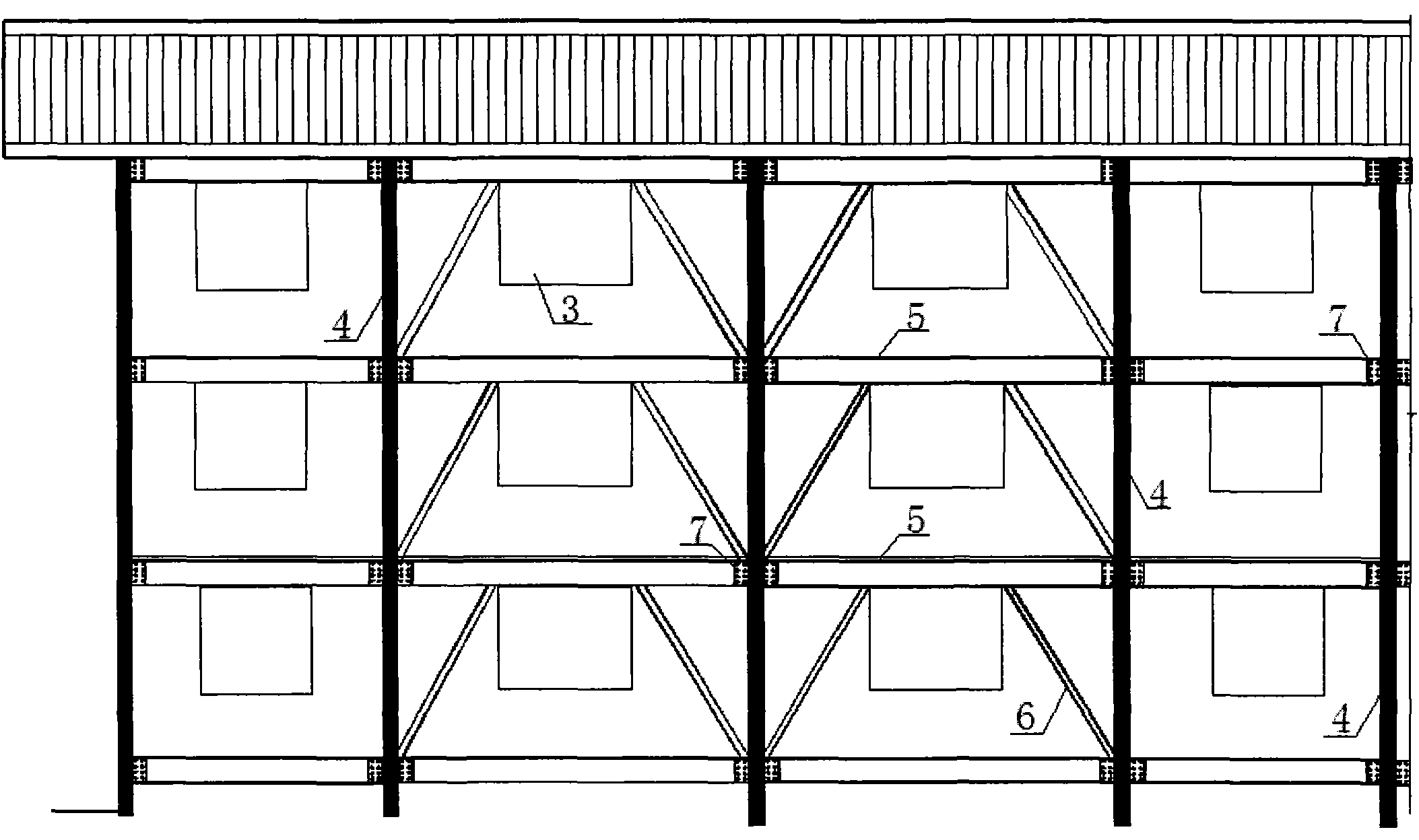

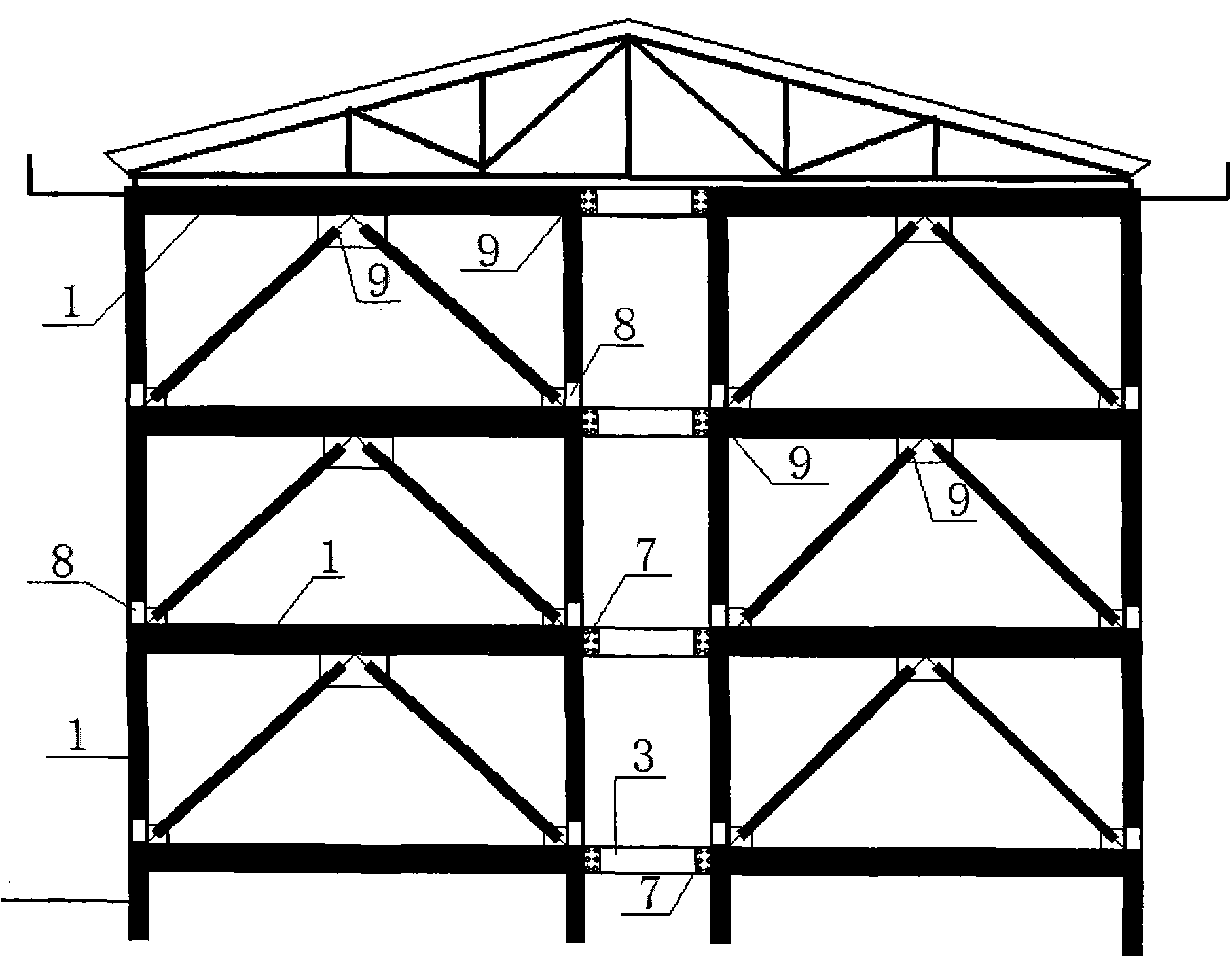

[0034] The specific embodiment of the present invention is as Figure 1-5 shown.

[0035] A prefabricated rural steel structure housing system, see Figure 1 to Figure 5 As shown, it includes plane assembly unit 1, three-dimensional assembly unit 2, staircase assembly unit 14 and individual component assembly unit 3, see figure 1 , the plane assembling unit 1 comprises a steel pipe concrete column 4 and an H steel beam 5 constituting a rectangular frame, four said plane assembling units 1 encircle said three-dimensional assembling unit 2, and at least one of said three-dimensional assembling unit 2 is said to be flat The herringbone support 6 is also set in the assembly unit 1, and the steel tube concrete column 4, the H steel beam 5 and the herringbone support 6 are used as load-bearing members, see figure 2 , image 3 . The square concrete-filled steel tube columns 4, H steel beams 5 and herringbone supports 6 form the plane assembly unit 1 of this housing system, such ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Section height | aaaaa | aaaaa |

| Storey height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com