A method for cooling and cooling cogeneration coal seams by water injection

A coal seam water injection, cooling and heating technology, applied in earthwork drilling, safety devices, mining equipment, etc., can solve the problems of resource waste, low temperature water not being fully utilized, etc., and achieve energy saving and good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0014] The cooling and heating cogeneration coal seam water injection cooling method of the present invention, its preferred embodiment is:

[0015] The low-temperature waste water generated by the ground heat pump is comprehensively used, and sent to the underground through the insulated water pipe, and the drill holes are arranged in the roadway near the coal mining face, and the low-temperature water is injected into the high-temperature coal body through the drill holes, so that the rock mass around the coal mining face is cooled.

[0016] The water outlet of the evaporator of the heat pump is externally connected with a large-diameter thermal insulation water pipe, which is used as a water injection main pipe and sent to the downhole through the auxiliary well;

[0017] The water injection main pipe is sent to each mining area along the air inlet road, and is tapped with small-diameter thermal insulation water pipes, which are water injection branch pipes, which are sent t...

specific Embodiment

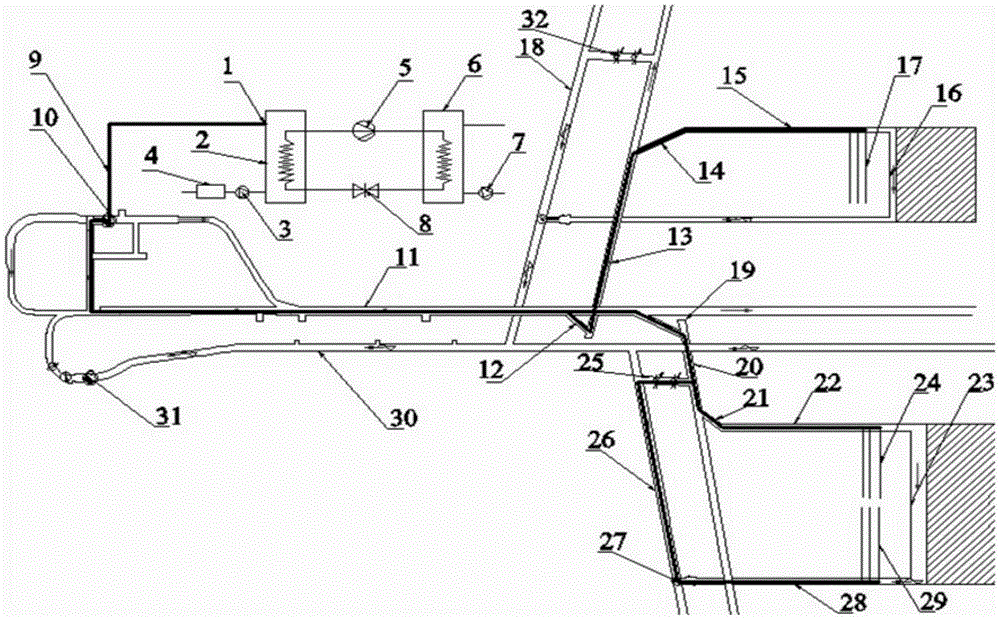

[0022] Such as figure 1 As shown, the water outlet 1 of the heat pump evaporator 2 is externally connected with a large-diameter thermal insulation water pipe 9, which is sent to the underground through the auxiliary shaft 10 (inlet shaft), and sent to each mining area along the air inlet road 11. Face 16, thermal insulation water pipe 9 enters the wind uphill through the mining area 13, the short working face enters the wind along the trough 15, and sends it to the vicinity of the short working face 16, and drills a downward long hole with a length of 30-100m along the direction of the coal seam inclination parallel to the working face 17. Perform static pressure or dynamic pressure water injection; for the long working face 23 with a long length, the thermal insulation water pipe 9 passes through the mining area and goes down the mountain 20. The direction is parallel to the working face, and the downward long hole 24 with a length of 30-100m is drilled to perform static pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com