Vehicle-mounted air energy power machine

An air energy and power machine technology, applied in the direction of machine/engine, rotary piston engine, rotary or oscillating piston engine, etc., can solve the problem of unsatisfactory vehicle power machine, achieve high kinetic energy utilization, less friction loss, long life of parts Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

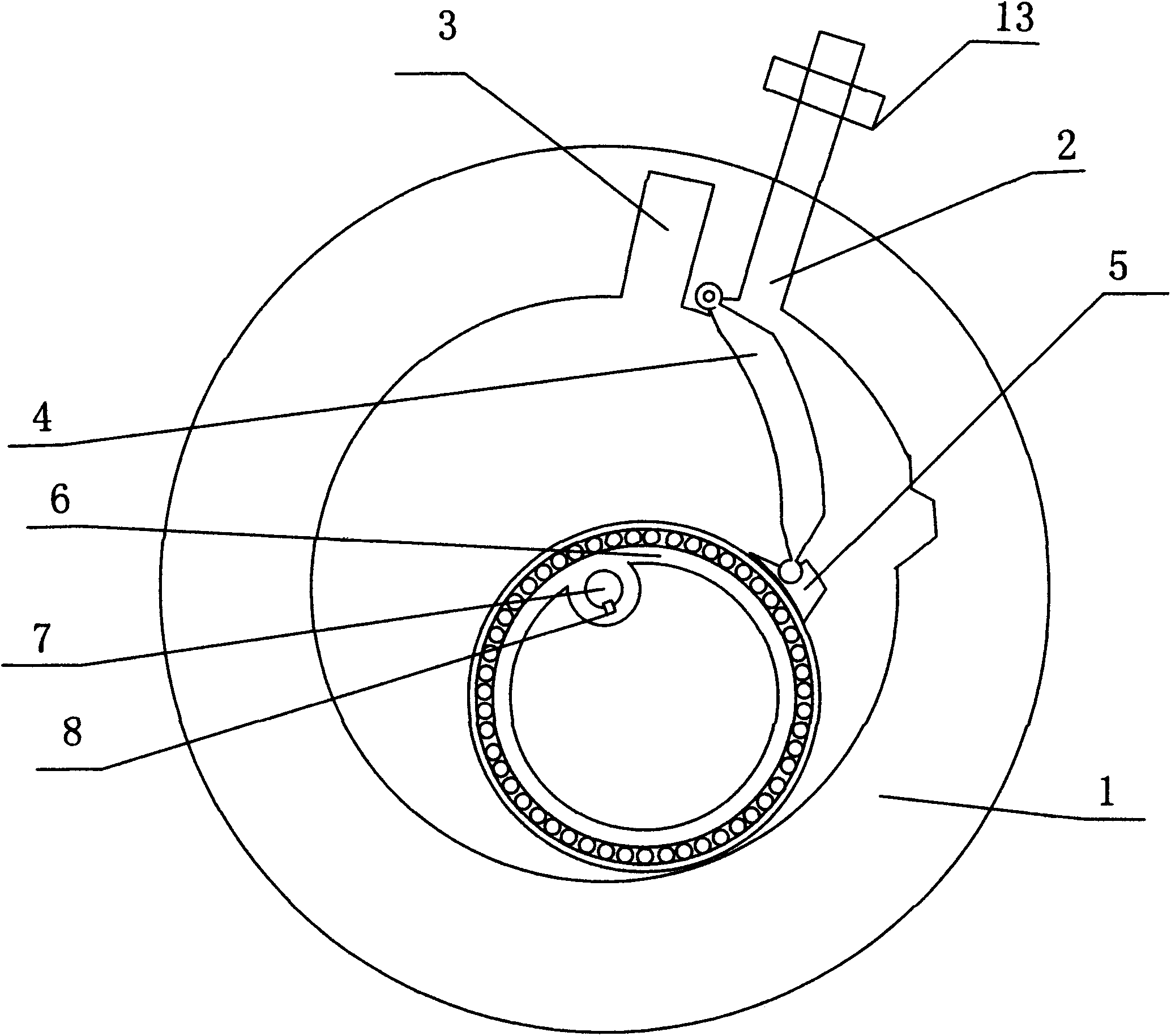

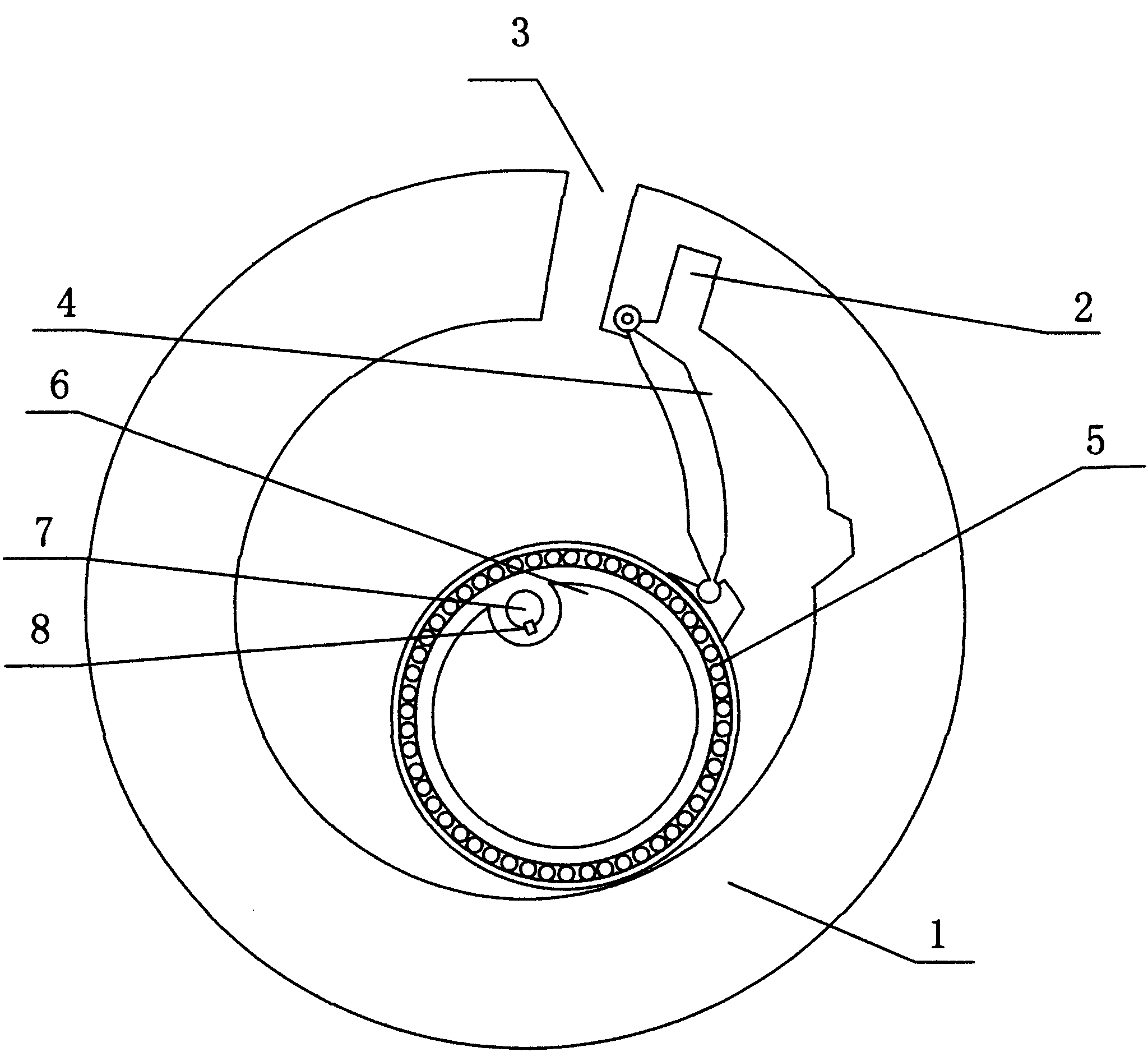

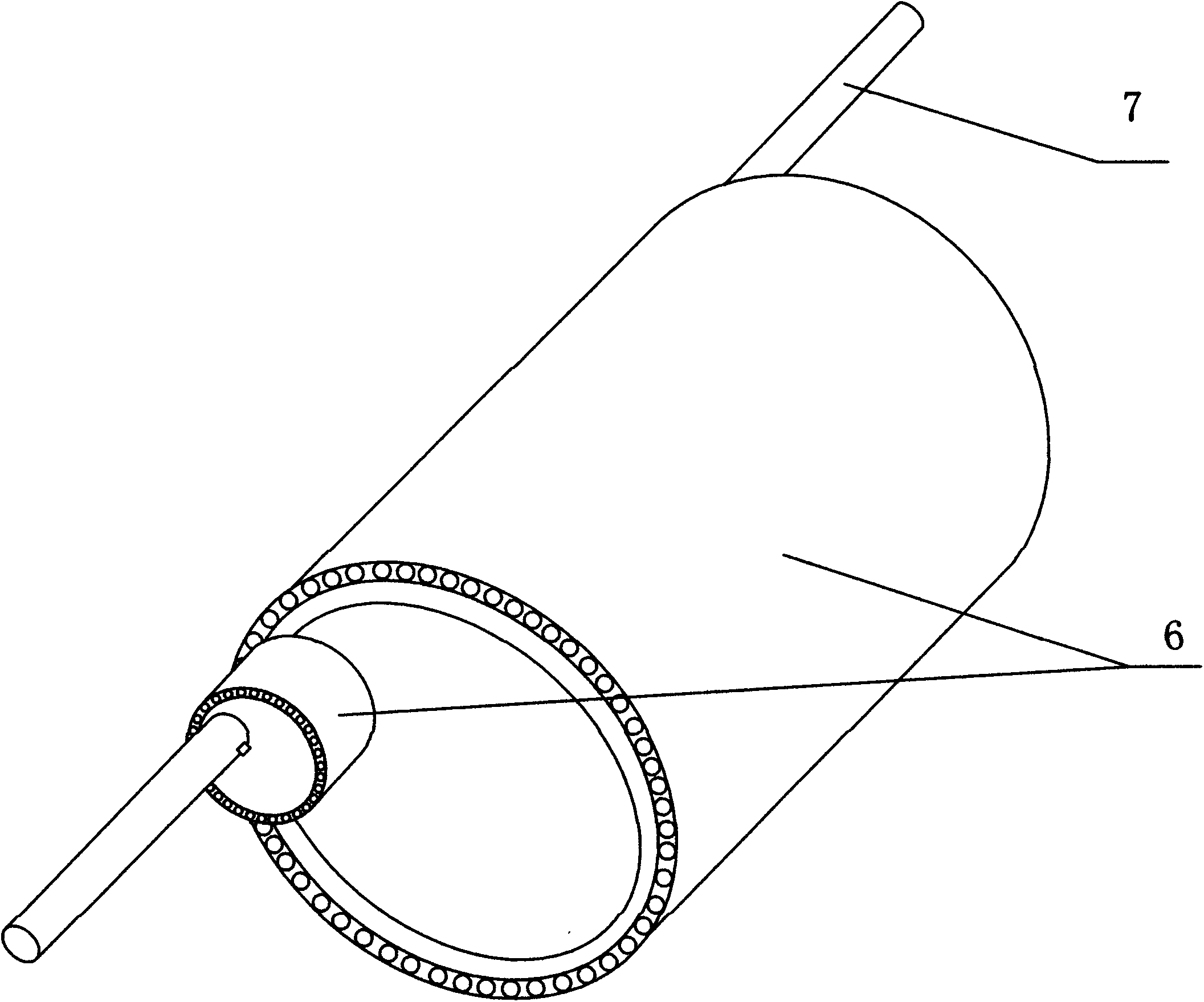

[0014] Figure 5 In the shown example, vaporization chamber (10) absorbs the heat in the air to vaporize the liquid nitrogen flowing in from liquid nitrogen tank (9), produces high-pressure nitrogen, opens switch (13), and high-pressure nitrogen enters the inlet of small working chamber (11) The air hole (2), the dividing plate (4) and the air pressure bearing (6) of the small working chamber (11) are pressed to move clockwise, driving the rotating shaft (7) to rotate clockwise to do work; Figure 6 , Figure 9 Shown: when the air pressure bearing (6) of small working chamber (11) rolled to the exhaust hole (3) of small working chamber (11), the air pressure bearing (6) of large working chamber (12) put dividing plate (4 ) withstand the air intake (2) of the large working chamber (12), and seal the air intake (2), which can prevent high-pressure nitrogen from leaking from the outside; Figure 7 , Figure 10 Shown: when the air pressure bearing (6) of small working room (11)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com