Assembled low-gravity-center efficient vertical shaft wind turbine

A low-center-of-gravity, vertical-axis technology, applied in the field of wind power generation equipment, can solve the problems of reducing the weight of the wind rotor, airflow interference, low strength and stiffness, etc., to reduce the weight of the wind rotor, easy to start and rotate the wind rotor, and avoid disturbing the airflow Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

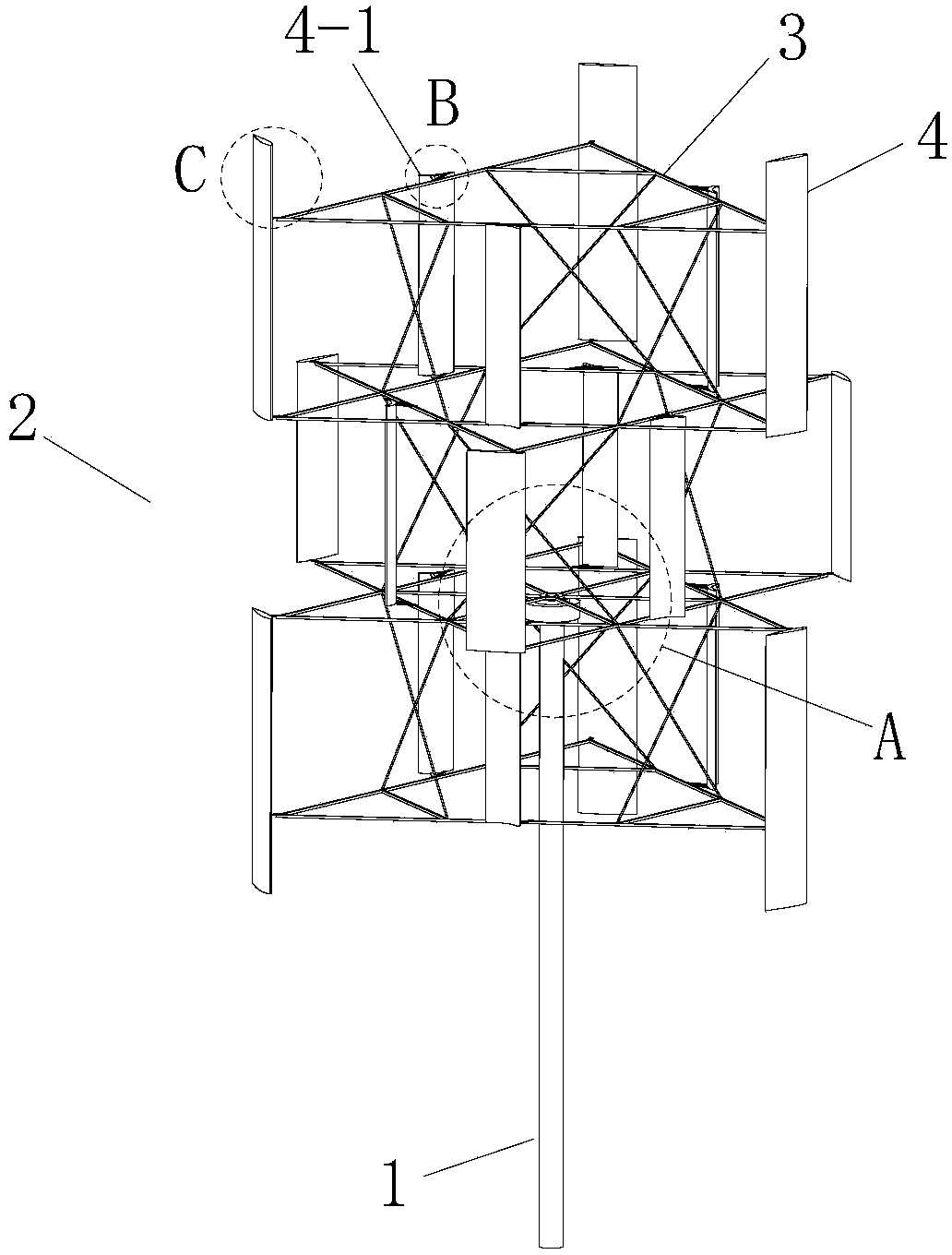

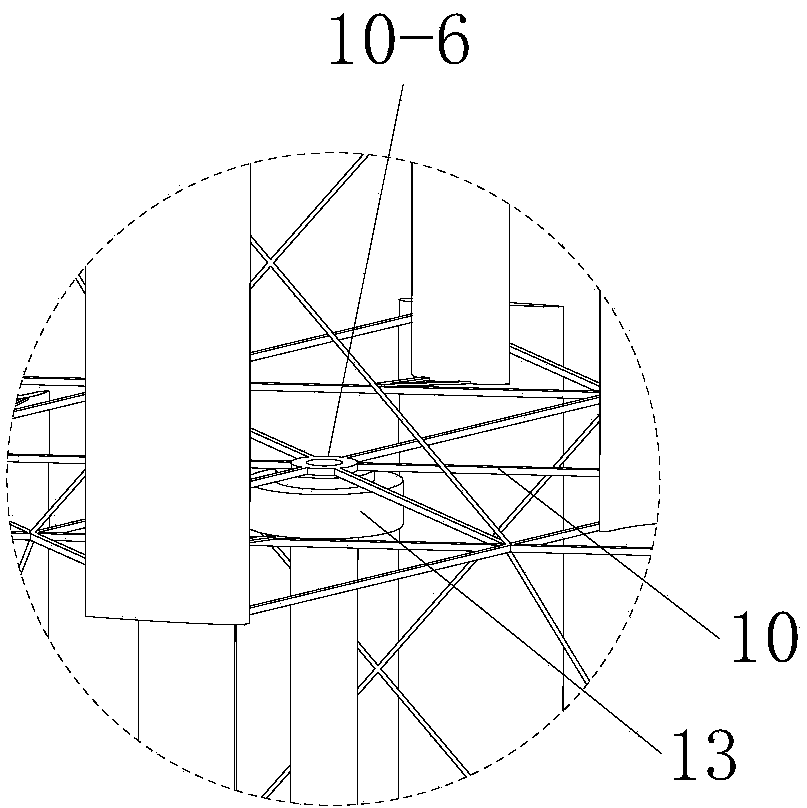

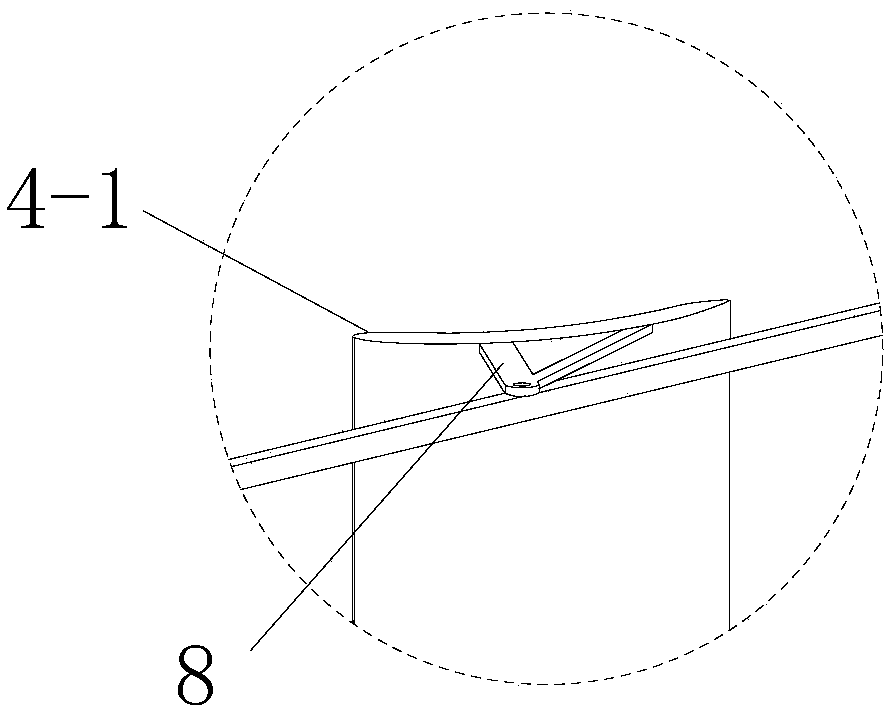

[0065] In this embodiment, the assembled low-gravity high-efficiency vertical axis wind turbine is as follows: Figure 1 to Figure 4 As shown, it includes a fixed tower 1 that determines the vertical axis of rotation and a wind wheel 2 supported on the tower 1, and the wind wheel 2 and the tower 1 constitute a horizontal rotation pair that is axially constrained; the wind wheel 2 includes a center of rotation supported on The wheel frame 3 of the tower 1, and the blades distributed on the periphery of the wheel frame 3; the blades include a group of alternately spaced first blades 4 and second blades 4-1; the first and second blades 4, 4-1 are respectively It is a vertically extending streamlined cross-section blade, the first blade 4 has an outward blade surface and an inward blade surface which are respectively convex and asymmetrically distributed on both sides of the blade chord; the second blade 4-1 The outer blade surface is concave and the inner blade surface is convex;...

Embodiment 2

[0073] In this embodiment, the assembled low-gravity high-efficiency vertical axis wind turbine is as follows: Figure 12 to Figure 17 Shown, its basic structure is identical with embodiment 1, and difference is only in:

[0074] (1) This embodiment adopts a single-layer structure formed by a connection frame 7 and a transmission frame 6 .

[0075] (2) A controller 12 for turning the angle of the blade is provided between the part of the fixing part 8 close to the blade 4-1 and the spokes of the transmission frame 6 or the connection frame 7 .

[0076] (3) if Figure 17 As shown, the transmission frame 6 is triangular as a whole.

[0077] (4) The connecting frame 7 has only one structural form, which is the same as Figure 8 Same as shown.

[0078] (5) The structure of the fixing part 4-2 is the same as that of the fixing part 8, both of which are the same as Figure 11 Same as shown.

Embodiment 3

[0080] In this embodiment, the assembled low-gravity high-efficiency vertical axis wind turbine is as follows: Figure 18 to Figure 23 Shown, its basic structure is identical with embodiment 1, and difference is only in:

[0081] (1) This embodiment adopts a double-layer structure formed by two connecting frames 7 and one transmission frame 6 .

[0082] (2) The connecting frame 7 has only one structural form, which is the same as Figure 8 Same as shown.

[0083] (3) The structure of the fixing part 4-2 is the same as that of the fixing part 8, both of which are the same as Figure 11 Same as shown.

[0084] (4) Telescopic controllers 12 for rotating the angle of the blades are respectively provided between the parts of the fixing part 4-2 and the fixing part 8 close to the blade 4-1 and the spokes of the transmission frame 6 or the connecting frame 7 .

[0085] In addition, if Figure 22 As shown, the rotation connection point between the fixed piece and the transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com