Flexible structure-variable compressed air energy storage system with vortex machines

A technology of compressed air energy storage and flexible variable structure, which is applied in the direction of compressors, irreversible cycle compressors, pump combinations for elastic fluid rotary piston type/swing piston type, etc., and can solve short-term fast-changing transient power Improve the problems of limited ability, slow dynamic response, and fixed structural power level, etc., to achieve the effect of solving insufficient power stabilization ability, reducing system power loss, and improving dynamic response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

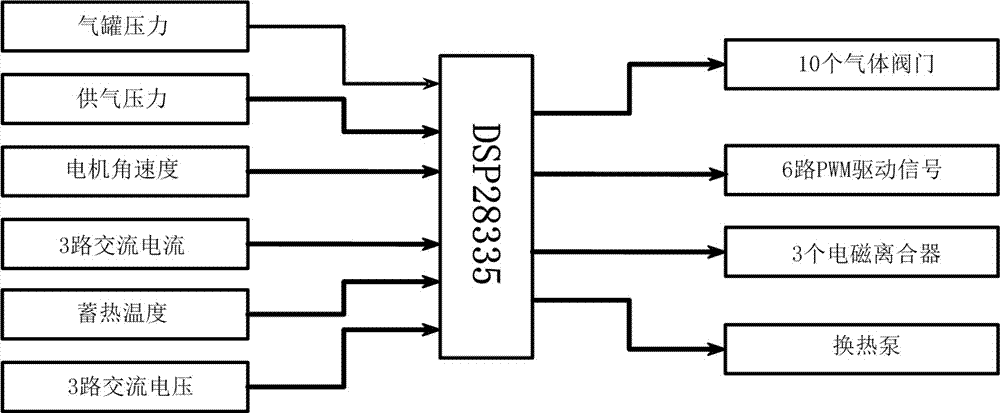

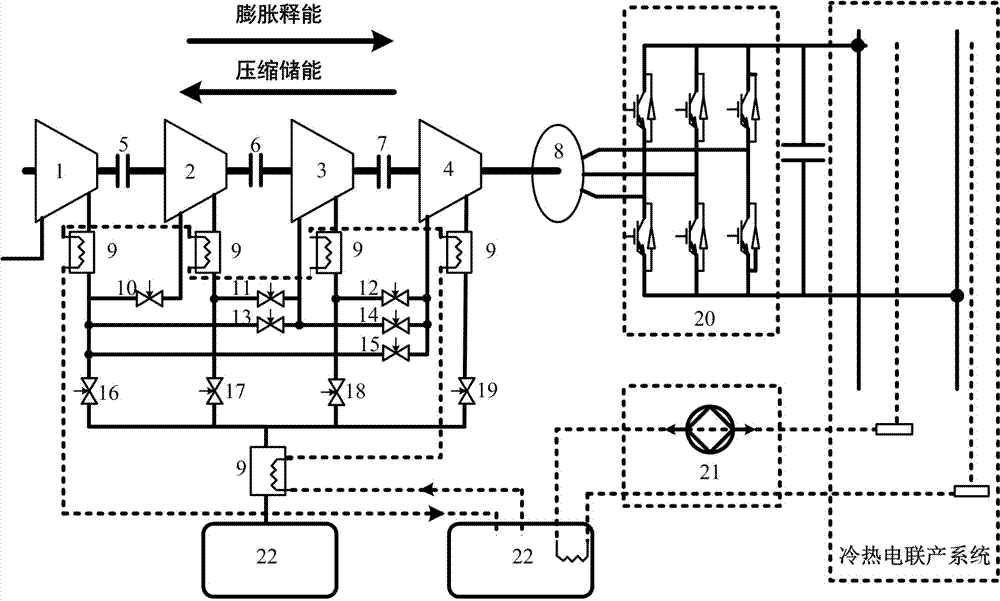

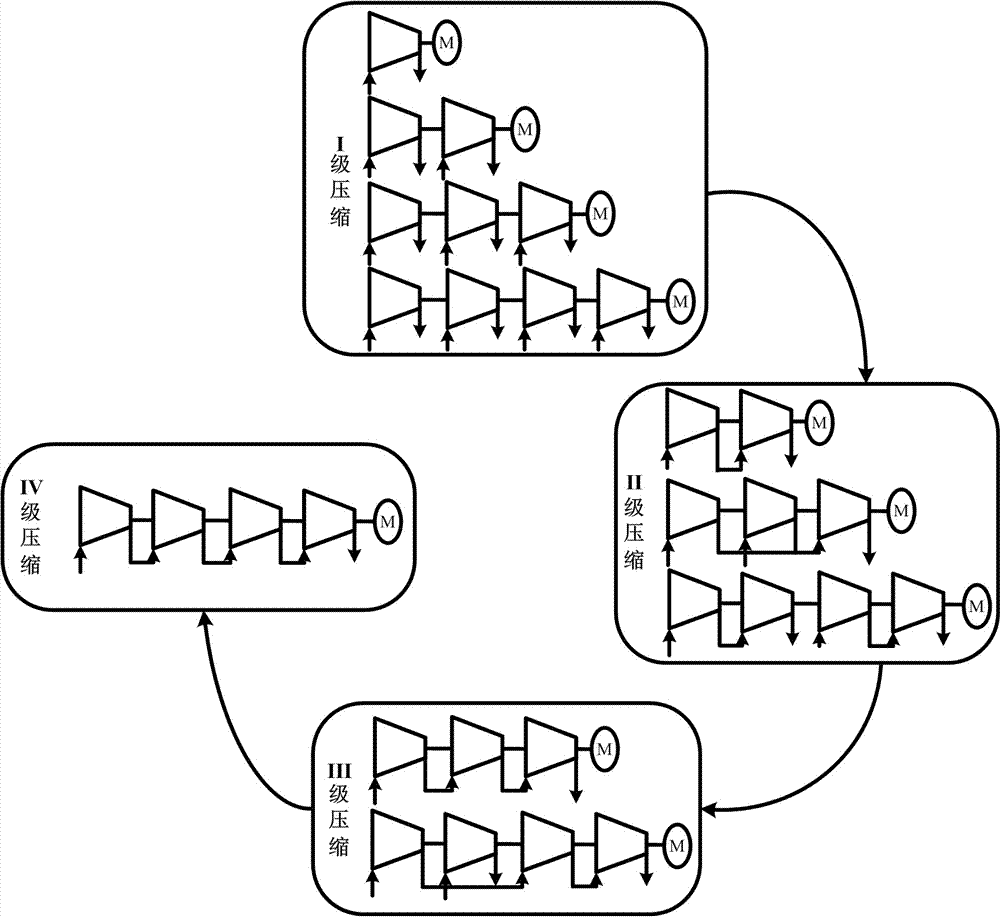

[0020] The salient feature of the present invention is that the flexible adjustment of the structure of the energy storage system can be formed through the optimized combination of the electromagnetic clutches (5-7) and the gas circuit valves (10-19), respectively. figure 2 Compression energy storage mode structure and image 3 Expansion energy release mode structure, because the air pressure of the gas tank gradually increases in the compression mode, the mechanism adjustment in the compression mode follows the single-stage to multi-stage arrows ( figure 2 ) transformation process, and at the same time, in order to reduce the impact caused by the structural adjustment, the scroll machines are coupled step by step (5-6-7); image 3 ). As for the flexible structure adjustment algorithm of the energy storage system, it is determined by Figure 4 The DS...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com