Self-priming burner

A burner, self-priming technology, applied in burners, gas fuel burners, combustion methods, etc., can solve the problems of difficult flame adjustment, inconvenient use, narrow application range, etc. Well-designed effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

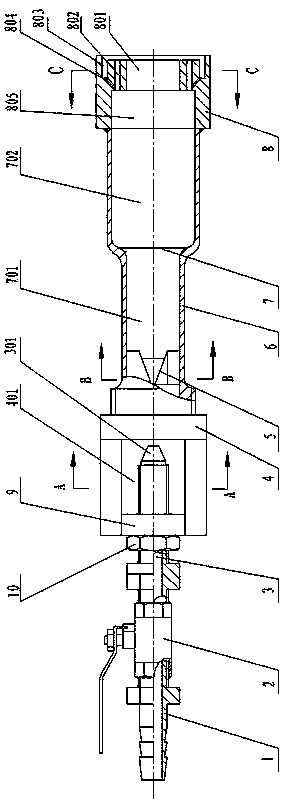

[0015] exist figure 1 Among them, a self-priming burner includes a body 6 , a gas connecting pipe 1 , a valve 2 , a gas nozzle 3 and a combustion nozzle 8 .

[0016] Such as figure 1 As shown, the valve 2 is installed between the gas connection pipe 1 and the gas nozzle 3 to control the connection or closure of the gas.

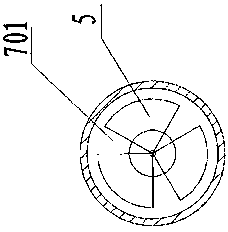

[0017] exist figure 1 Among them, the interior of the body 6 is opened with a through injection cavity 7 .

[0018] Such as figure 1 As shown, the injection cavity 7 is composed of a first injection cavity 701 and a second injection cavity 702 , wherein the cross-sectional area of the second injection cavity 702 is larger than that of the first injection cavity 701 . According to the entry path of the mixed gas, the cross-sectional area of the gas channel changes from small to large, so that the mixed gas entering the second injection cavity 702 can be mixed again.

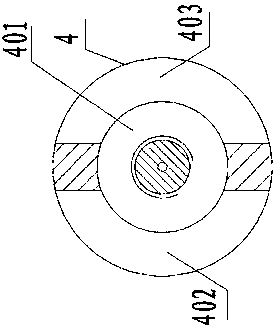

[0019] exist figure 1 Among them, a gas regulating seat 4 is installed on the begin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com