Hard alloy cutter surface coating etchant and application method thereof

A cemented carbide and surface coating technology, applied in the field of alloy cutting tools, can solve the problems of complex sample production and inability to track in time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 1. Sample preparation: (1) Hot-press mounting: Take the sample (alumina hard-coated tool prepared by high-temperature chemical vapor deposition method), and use phenolic resin powder as filler to make a regular cylinder with a diameter of 30mm on a hot-press mounting machine For the sample, the molding temperature is 130°C, and the pressure is kept for 5 minutes. (2) Grinding: The inlaid samples are fully coarsely ground and finely ground on 600 mesh and 1200 mesh diamond grinding wheel discs respectively, and the time of coarse and fine grinding is controlled at about 5 minutes. The temperature is 500r / min, and the cooling water is continuously passed during the grinding process. The sample should be fully ultrasonically cleaned between coarse and fine grinding (ultrasonic cleaning time in anhydrous ethanol for 2min) and dried in an oven at 100°C to remove abrasive particles. crumbs and oil.

[0022] (3) Polishing: After the sample is ground, it is polished with W2.5 ...

Embodiment 2

[0027] 1. Sample preparation: (1) Hot press mounting: Same as Example 1. (2) grinding: with embodiment 1. (3) polishing: same as embodiment 1.

[0028] 2. Preparation of etchant: measure 35ml of concentrated HNO with a glass measuring cylinder 3 , 5ml concentrated HCl and 10ml H 2Add O into a plastic beaker, then use a plastic measuring cylinder to measure 10ml of concentrated HF, add it to the beaker, put it in an ultrasonic machine and sonicate for 2 minutes until the solution is evenly mixed.

[0029] 3. Etching operation: Etching is carried out as in Example 1, and the etching time is 30s.

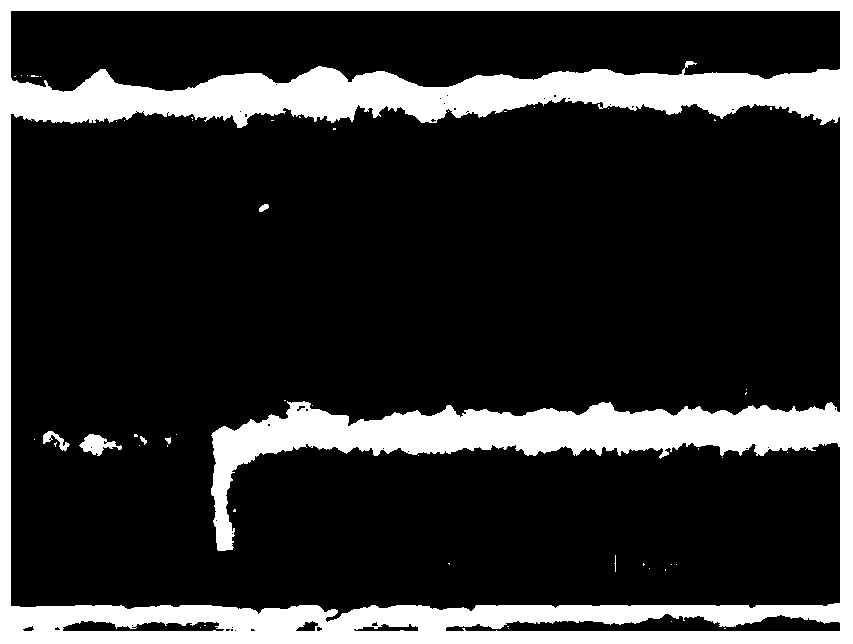

[0030] figure 2 It is the cross-sectional morphology of the sample after etching. Compared with Example 1, the volume of concentrated hydrochloric acid in the etchant composition increases, but the etching time is reduced to 30s. Compared with the morphology of Example 1, it is found that the coating shows The area of the prismatic structure increases, and some grain boundaries...

Embodiment 3

[0032] 1. Sample preparation: (1) Hot press mounting: Same as Example 1. (2) grinding: with embodiment 1. (3) polishing: same as embodiment 1.

[0033] 2. Preparation of etchant: Measure 35ml of concentrated HNO with a glass measuring cylinder 3 , 5ml concentrated HCl and 10ml H 2 Add O into a plastic beaker, then use a plastic measuring cylinder to measure 10ml of concentrated HF, add it to the beaker, put it in an ultrasonic machine and sonicate for 2 minutes until the solution is evenly mixed.

[0034] 3. Etching operation: Etching is carried out as in Example 1 for 40 s.

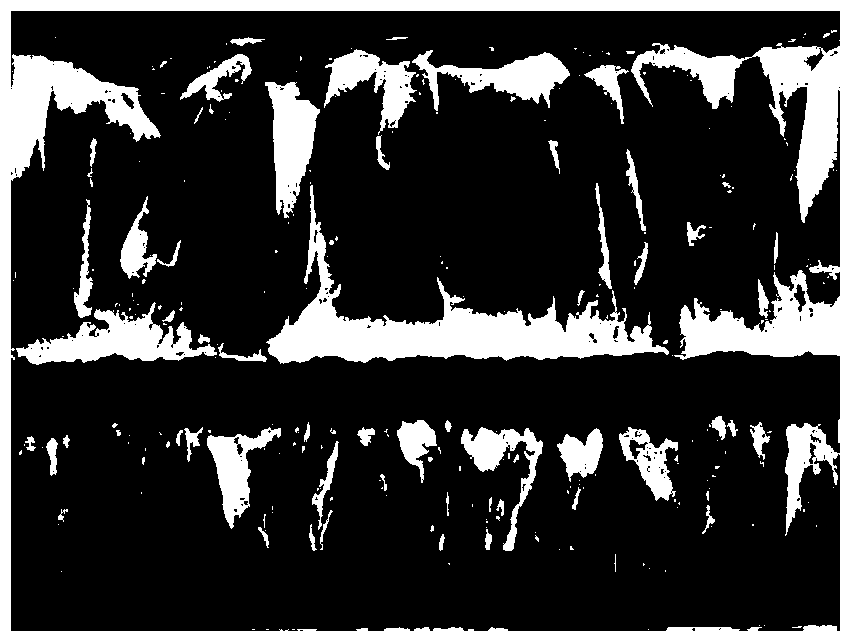

[0035] image 3 It is the cross-sectional morphology of the sample after etching. The volume of hydrochloric acid in the etchant in this example has increased compared with Example 1. Compared with Example 2, the etching time has increased to 40s. It can be clearly observed from the figure The irregular prismatic grains of the alumina coating and the columnar crystal growth method can also effective...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com