Method and system for testing OLED display device

A technology for display devices and testing methods, applied in photometry, static indicators, electrical solid devices, etc., can solve problems such as restricting the testing and repairing of OLED backplane finished products, limited accuracy, data analysis, etc., to improve testing efficiency. and test intuitiveness, reducing the effect of test cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

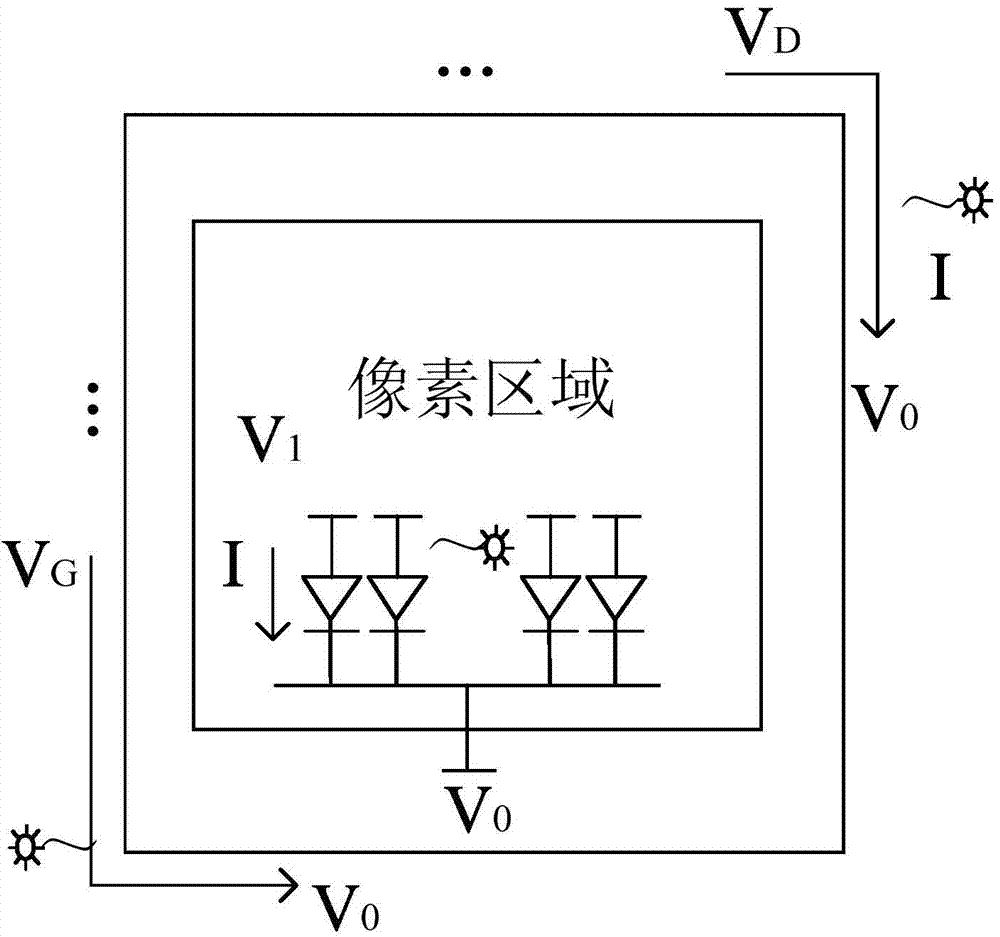

[0101] Example 1: The OLED display device to be tested is an AMOLED-IGZO-TFT backplane with a 2T1C structure

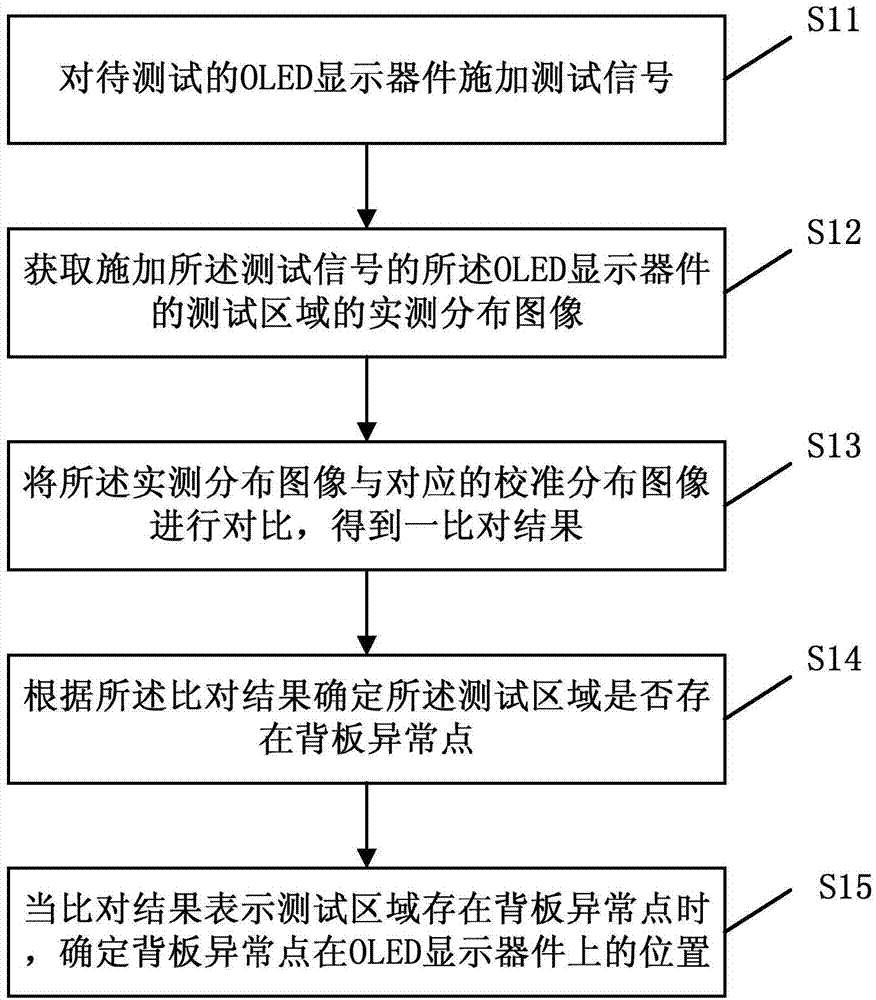

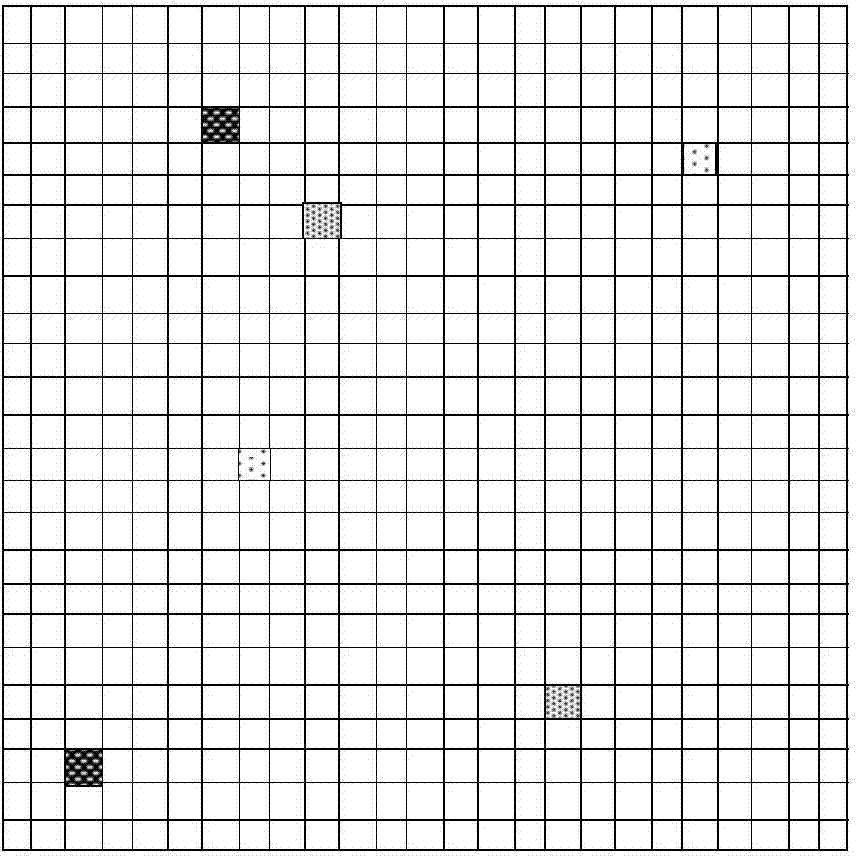

[0102] The testing method of the OLED display device according to Embodiment 1 of the present invention comprises the following steps:

[0103] Step S21: placing the to-be-tested IGZO-TFT backplane that has completed the array substrate (Array) process on the test platform;

[0104] Step S22: using a photon-sensing infrared CCD imager to capture the alignment mark (Mark) of the IGZO-TFT backplane, and align the position of the IGZO-TFT backplane according to the alignment mark.

[0105] Step S23: After aligning the position, attach an OLED circuit simulation board on the IGZO-TFT backplane, after the circuit simulation board is bonded to the IGZO-TFT backplane, the IGZO-TFT backplane The circuit elements are connected with the circuit elements on the OLED circuit simulation board to form a test loop. A photon-sensing infrared CCD imager is used to scan and move from...

Embodiment 2

[0109] Embodiment 2: The OLED display device to be tested is an AMOLED-LTPS-TFT backplane with a 4T2C structure including a compensation circuit

[0110] The testing method of the OLED display device of the second embodiment of the present invention comprises the following steps:

[0111] Step S31: placing the to-be-tested LTPS-TFT backplane on which the array substrate process has been completed on the test platform;

[0112] Step S32: Using a photon-sensing infrared CCD imager to capture the alignment mark on the LTPS-TFT backplane, and align the position of the LTPS-TFT backplane according to the alignment mark.

[0113]Step S33: After aligning the position, attach an OLED circuit simulation board on the LTPS-TFT backboard, and after the OLED circuit simulation board is bonded to the LTPS-TFT backboard, the LTPS-TFT backboard The circuit elements are connected with the circuit elements on the OLED circuit simulation board to form a test loop. A photon-sensing infrared CCD...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com