Anti-flaming fireproof cable for electric welding machine

A flame-retardant, fire-resistant, electric welding machine technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of affecting cable protection, insulation performance, high cable production cost, over-sulfur conductors, etc., to solve the problem of cable damage and reduce short circuits. Accident hidden danger, the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

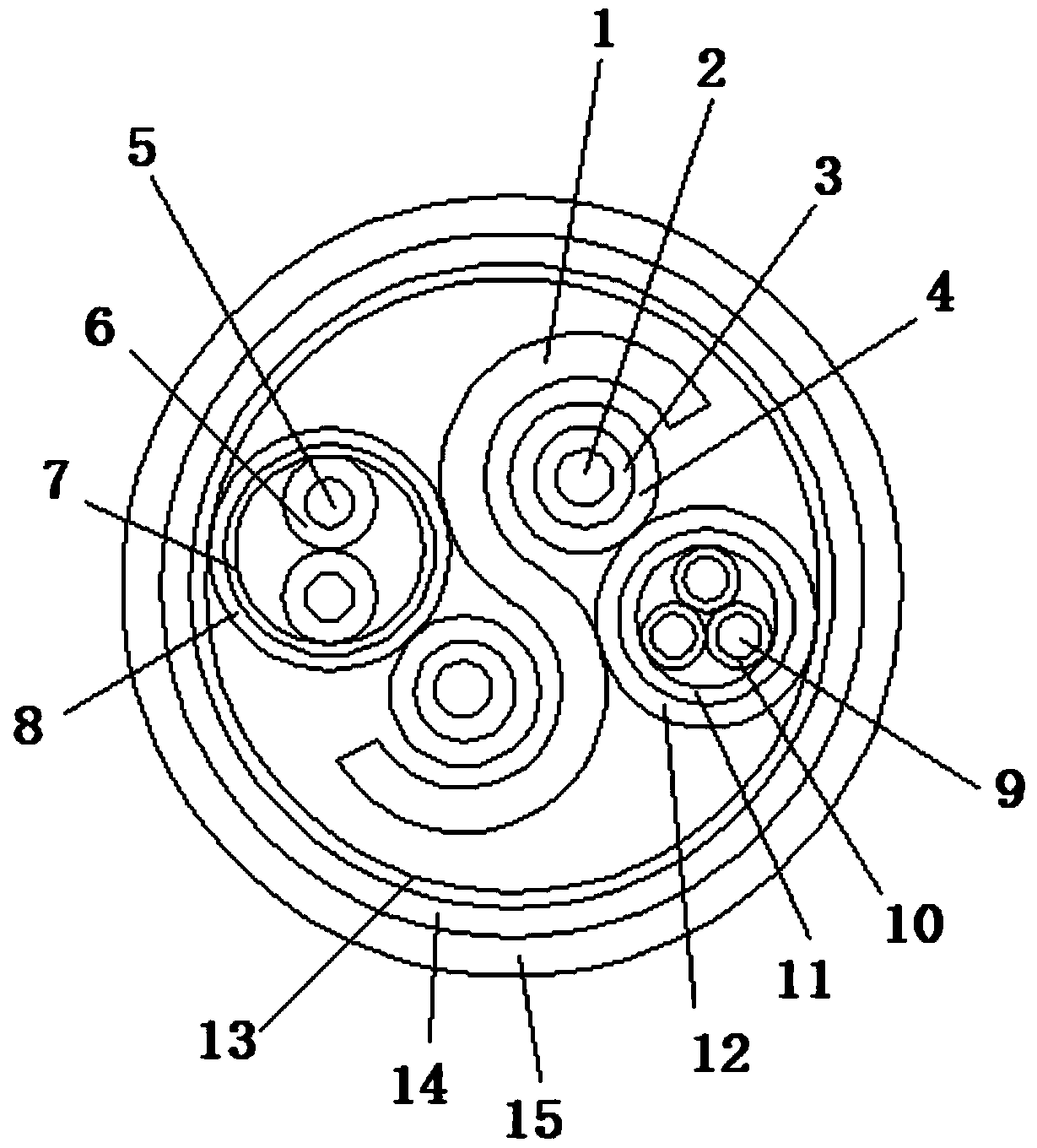

[0015] Such as figure 1 As shown, a flame-retardant and fire-resistant cable for an electric welding machine includes a cable core, and the cable core includes an S-shaped nylon skeleton 1, and a main conductor 2 is respectively arranged in a semicircular arc at both ends of the S-shaped nylon skeleton 1, and the main conductor 2. TPE thermoplastic elastomer 3 and flame-retardant nylon composite insulating layer 4 are wrapped to form the main wire core. The two sides of the S-shaped nylon skeleton 1 are respectively equipped with a power wire core and a control wire core. The power wire core includes two The power conductor 5 and the power conductor 5 are respectively wrapped with a polyvinyl chloride insulating layer 6 and then twisted, and the outside of the twisted pair is covered with an inner lining layer 7 and a mica layer 8 in turn; the control line core includes three control conductors 9, the control conductor 9 Wrapped with silicone rubber insulating layer 10 and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com