Organic light-emitting display device and manufacturing method thereof

A technology of light-emitting display and manufacturing method, which is applied in the manufacturing of semiconductor/solid-state devices, semiconductor devices, electrical components, etc., can solve the problems of scratches, touches, low yield of OLED displays, and many defective products, etc., to improve the yield Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] As mentioned in the background section, the yield rate of OLED displays in the prior art is low.

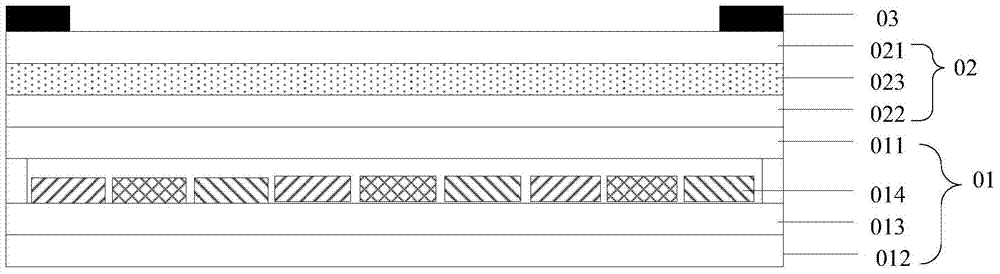

[0032] Moreover, in the OLED display in the prior art, the OLED display panel includes: an upper substrate and a lower substrate, a TFT wiring layer located on the lower substrate facing the surface of the upper substrate, and a TFT wiring layer located on the surface of the TFT wiring layer. Organic light-emitting layer; the touch panel includes: an upper substrate and a lower substrate, and a touch electrode layer located between the upper substrate and the lower substrate, so that after the OLED display panel and the touch panel are assembled together, As a result, the thickness of the OLED display in the prior art is relatively large.

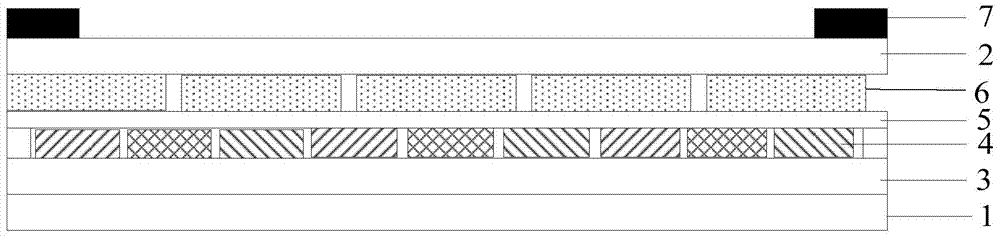

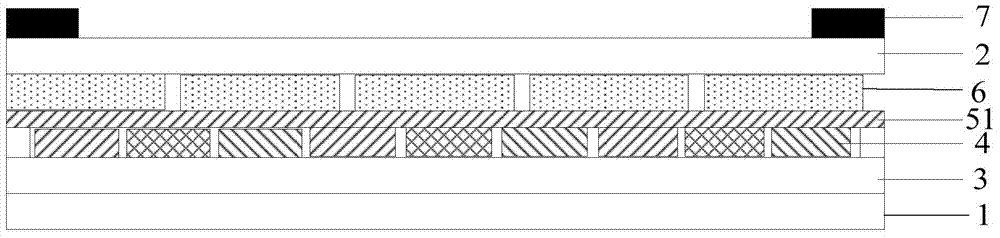

[0033] In view of this, an embodiment of the present invention provides an organic light emitting display device, including:

[0034] a first substrate and a second substrate oppositely arranged;

[0035] a TFT wiring layer disposed o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com