1216-nm all-solid raman laser

A Raman laser, all-solid-state technology, applied in the laser field, achieves the effect of strong absorption, increased output power, and small water absorption coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

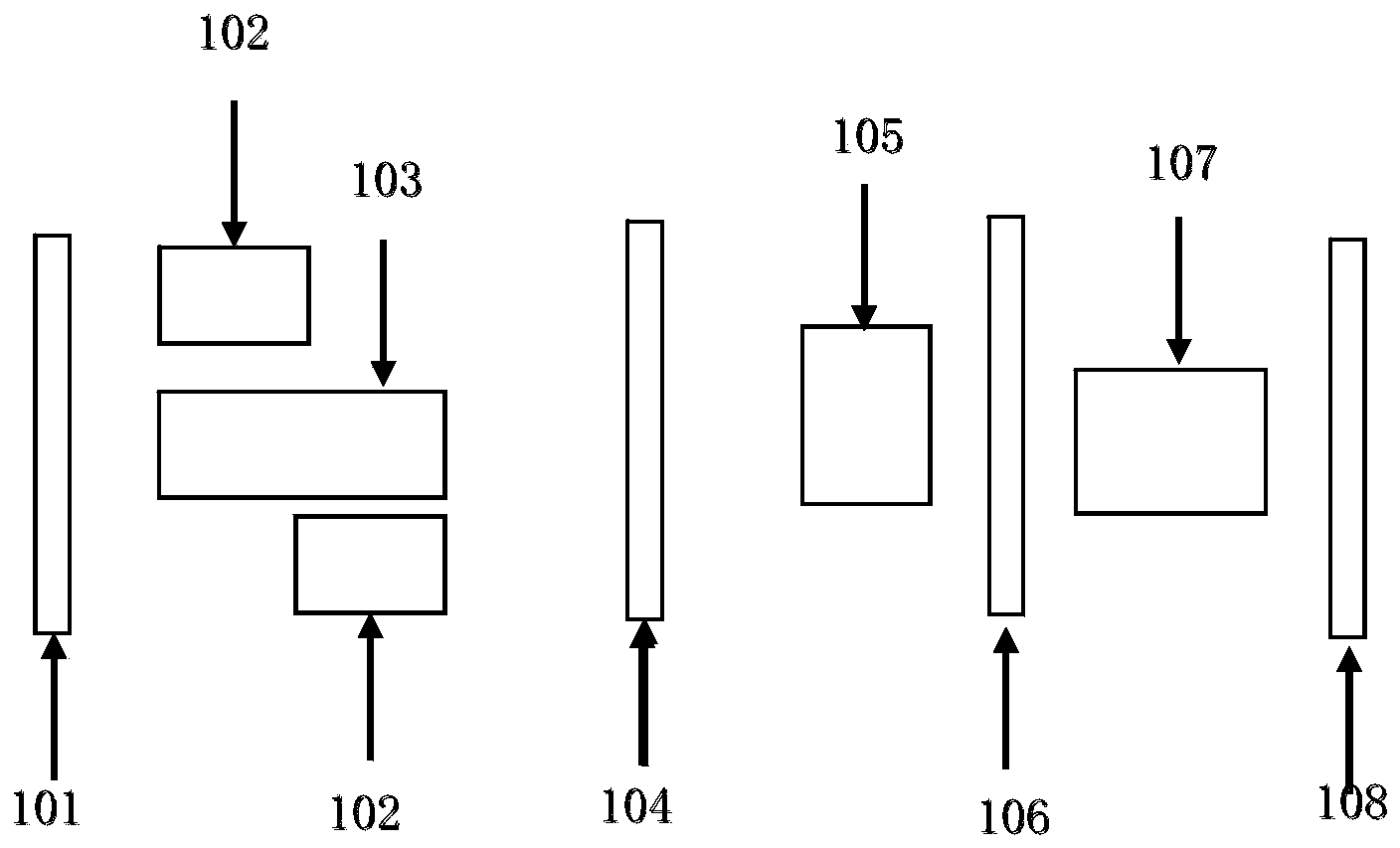

[0009] The following is attached figure 1 The present invention is further described with embodiment:

[0010] The structure of a 1216nm all-solid-state Raman laser is as follows figure 1 As shown, it includes a 1079nm fundamental frequency optical resonator front cavity mirror 101, a side pump source 808nm semiconductor laser 102, a Nd:YAP crystal 103, a 1079nm quarter-wave plate 104, a KD*P electro-optic Q-switched crystal 105, and a Raman Resonant cavity front cavity mirror 106, Raman crystal Ba(NO 3 ) 2 107 and coupled out mirror 108. Nd:YAP crystal 103, 1079nm quarter-wave plate 104, KD*P electro-optic Q-switching crystal 105, pump The source 102 is placed on both sides of the Nd:YAP crystal 103, and it is ensured that the pump light does not enter the opposite semiconductor laser to avoid damage to the pump source. Raman crystal Ba(NO 3 ) 2 . The front cavity mirror 106 of the Raman resonator is coated with a 1079nm high reflection film on the front cavity mirror...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com