Mulberry leaf picking machine

A picking machine and mulberry leaf technology, applied in the field of household crop picking machinery, can solve the problems of inability to meet feeding needs, labor and time consumption, and reduced economic benefits, and achieve the effects of convenient machine operation, reduced machine weight, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

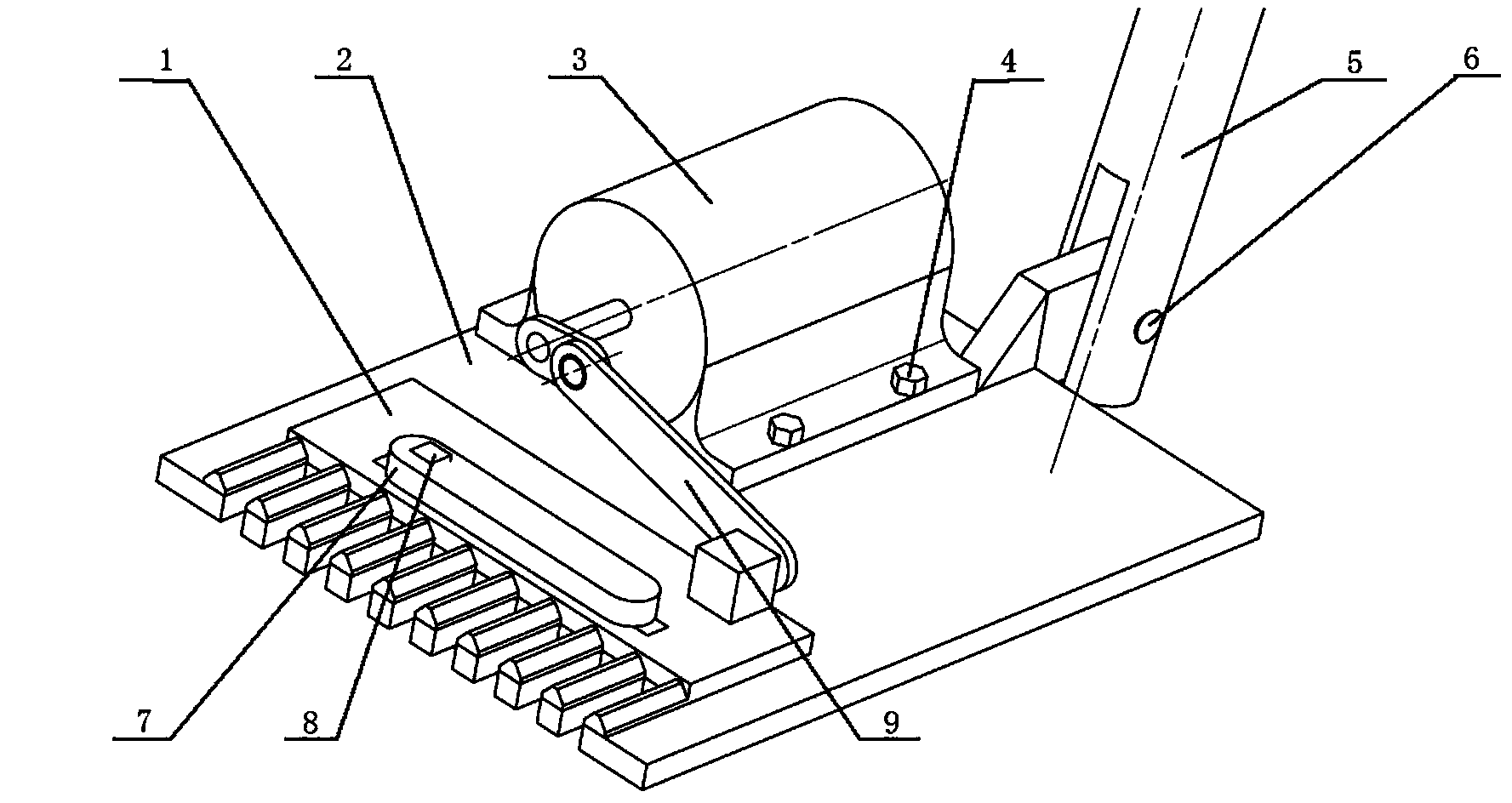

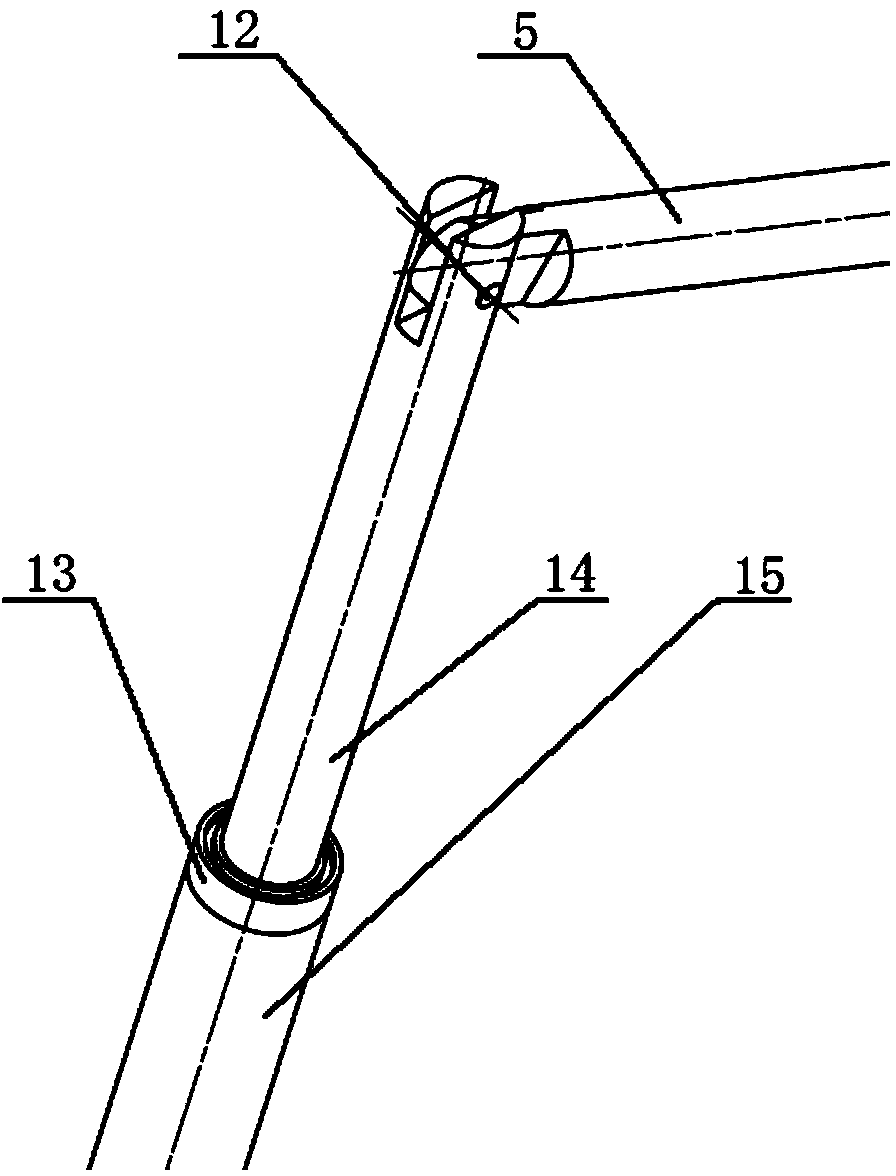

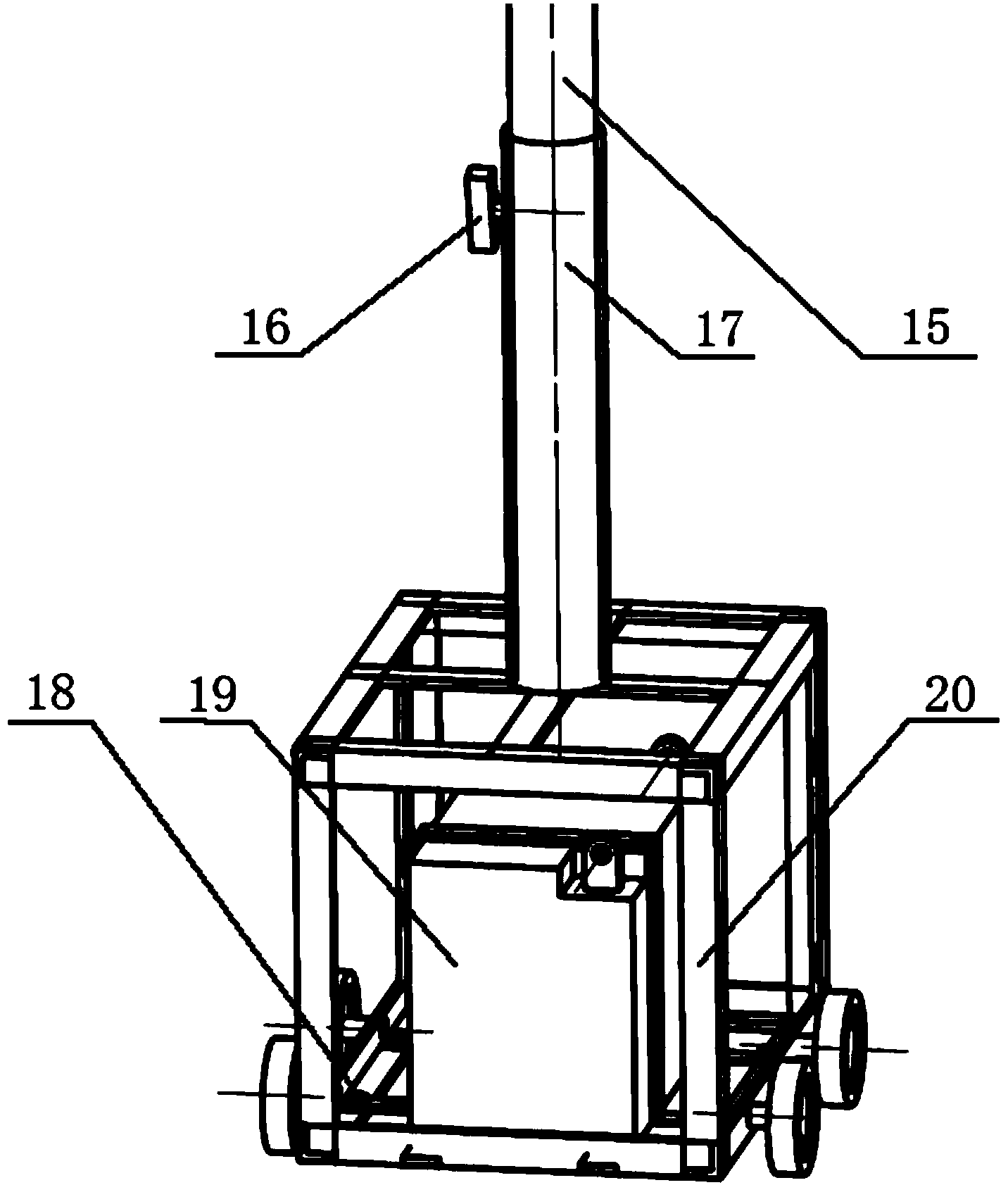

[0022] like Figure 1 to Figure 6 As shown, the mulberry leaf picking machine of the present invention includes an upper blade 1, a lower blade 2, a motor 3, a motor fixing screw 4, a first support rod 5, a first sliding bearing 6, an annular clamp 7, and a positioning block 8 , connecting rod mechanism 9, guide groove 10, sipe 11, second sliding bearing 12, rolling bearing 13, second support rod 14, third support rod 15, adjusting and fixing device 16, fourth support rod 17, fixing fixture 18, Storage battery 19, trolley 20, operating handle 21, shell 22 and shell fixing screw 23. The specific structure and connection method are as follows: the storage battery 19 is fixed on the dolly 20 through the fixing fixture 18, the fourth support rod 17 is welded together with the dolly 20, the fourth support rod 17 is connected with the third support rod 15 by adjusting the fixing device 16, and the fourth support rod 17 is connected with the third support rod 15 by adjusting the fixi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com