Industrial giant salamander breeding pond

A technology for breeding ponds and giant salamanders, applied in animal husbandry, etc., can solve problems such as reducing water exchange rate, achieve the effect of reducing consumption, reducing stress, and promoting large-scale high-density breeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

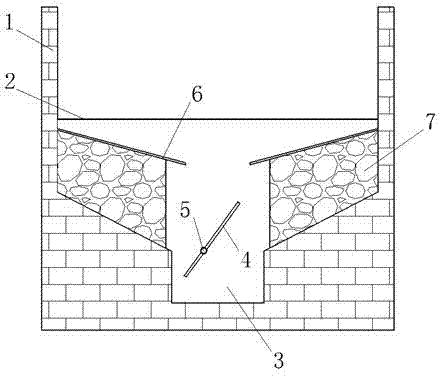

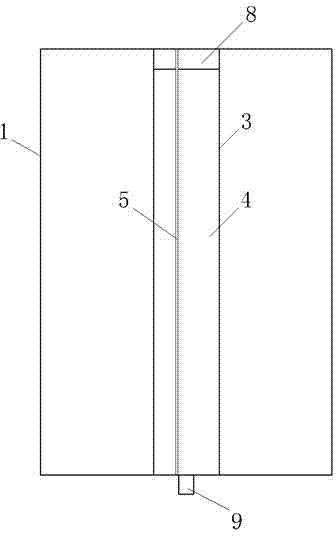

[0024] Giant salamander industrial culture pond of the present invention, its structure schematically is as follows figure 1 and figure 2 As shown, it includes a rectangular pool body 1 with a width of 1.4m-1.8m and a width of 0.6m-0.8m. A culture net 2 made of a flexible material that is detachably connected is provided at a depth of about 0.5m in the pool body. Along the length direction of the pool body 1, a drainage ditch 3 is provided in the middle of the bottom of the pool, and the bottom of the pool on both sides of the drainage ditch 3 is inclined to the water outlet 9. The upper part is provided with a cover plate 4 that can be opened and closed. The cover plate 4 can be opened and closed on the drain ditch 3 through the rotating shaft 5 along the length of the drainage ditch 3, and the rotating shaft 5 is set eccentrically on the axis of the length of the cover plate 4 to drain water. The pool body 1 at the end of the ditch 3 is provided with a drain 9 .

[0025] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com