Efficient and energy-saving vertical mill grading system

A grading system, high-efficiency and energy-saving technology, applied in the direction of grain processing, etc., can solve the problems of low precision, high energy consumption, qualified particles cannot be sent to the powder separator with high efficiency, etc., to reduce the internal circulation load and increase energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

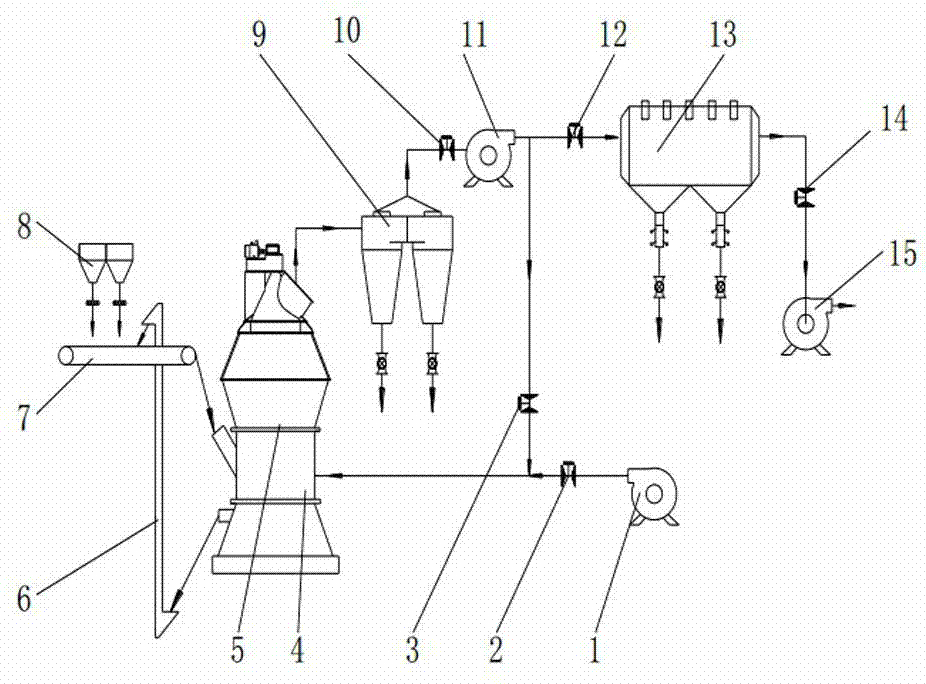

[0012] An embodiment of the present invention is as shown in the accompanying drawings of the specification, and it is realized by adding a circulating air device on the basis of the existing vertical mill classifier, and its circulating air device consists of a circulating fan 11 and a circulating air valve 12 composition. It includes hot air fan 1, hot air valve 2, mill air inlet valve 3, vertical mill 4, vertical mill powder separator 5, elevator 6, conveyor 7, batching device 8, cyclone 9, cyclone outlet valve 10, Circulating fan 11, circulating air valve 12, dust collector 13, dust collector air outlet valve 14, harvester fan 15, the inlet of its circulating fan 11 is connected with the harvester fan 15 and the outlet passes through the circulating air valve 12 and the mill The air inlet valve 3 is connected, and the air volume of the vertical mill classification process system can be changed by adjusting the frequency of the circulating fan 11.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com