Turning and milling compound machine for screwdriver head

A screwdriver head and compound machine technology, applied in the direction of metal processing machinery parts, other manufacturing equipment/tools, large fixed members, etc., can solve the problems of reduced processing accuracy, processing efficiency, and high processing cost, and achieve fast processing speed and processing accuracy High, space-saving and processing cost-effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

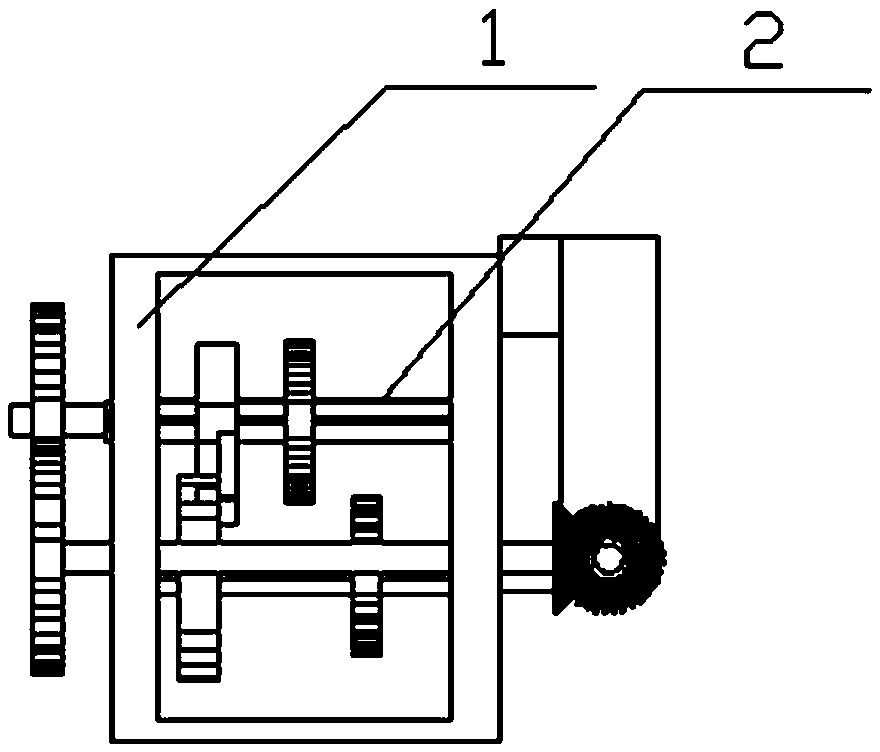

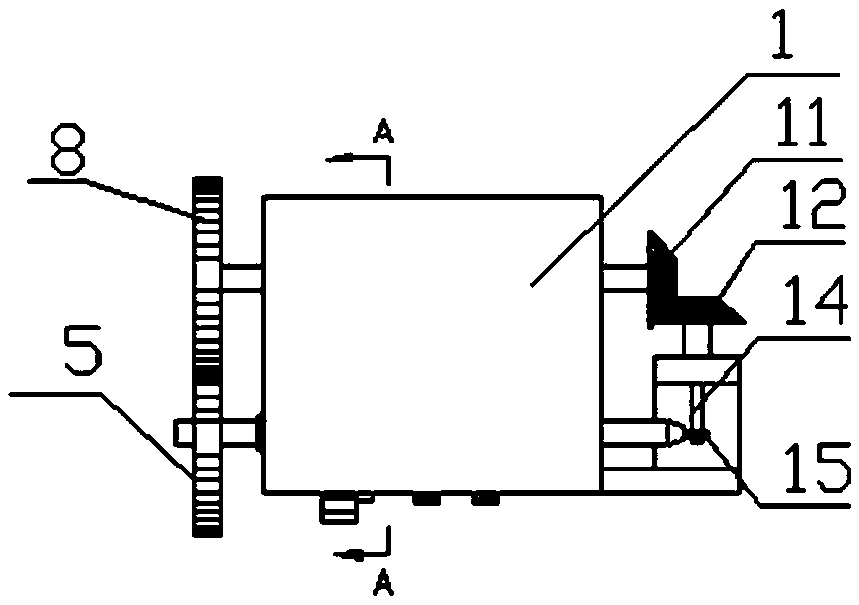

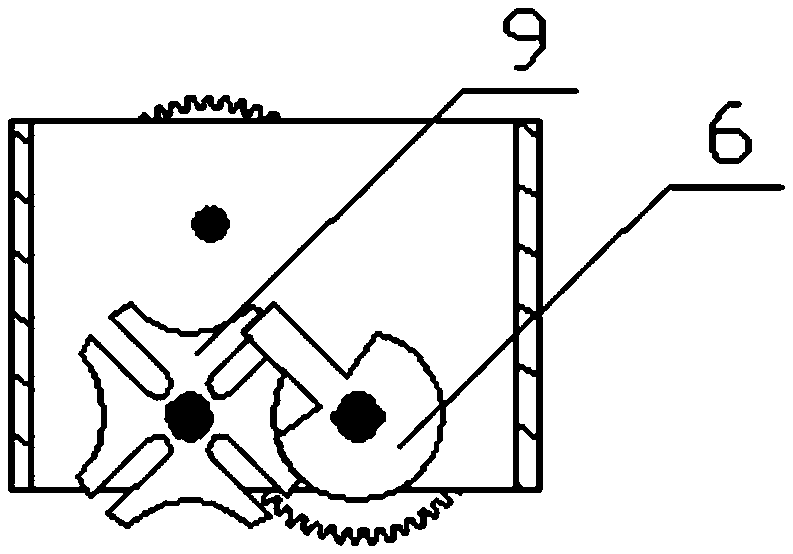

[0019] Embodiment: A screwdriver head turning and milling compound machine, including a spindle box 1, a driving shaft 2, a driven shaft 3, a turning and milling spindle 4, a first driving meshing wheel 5, a second driving meshing wheel 6, and a third driving meshing wheel 7. The first driven meshing wheel 8, the second driven meshing wheel 9, the third driven meshing wheel 10, the first bevel gear 11, the second bevel gear 12, the knife rest 13 and the power output device, the drive shaft 2. The driven shaft 3 and the turning-milling spindle 4 can be rotated and positioned in parallel in the headstock 1. The power output device drives the driving shaft 2 to rotate. The first driving meshing wheel 5 is fixed on one end of the driving shaft 2. The first driven meshing wheel 8 is fixed on one end of the driven shaft 3, and the first driving meshing wheel 5 is meshed with the first driven meshing wheel 8 for transmission, the second and third driving meshing wheels can be synchron...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com