Welding management system applicable to hot melting welder for plastic pipes

A hot melt welding and management system technology, applied in data processing applications, program control in sequence/logic controllers, resources, etc., can solve the impact of surface temperature, cooling time, and non-traceable plastic pipe hot melt welding Management system, lack of plastic pipe hot-melt welding environmental monitoring, parameter records and other issues, to achieve the effect of convenient control and inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

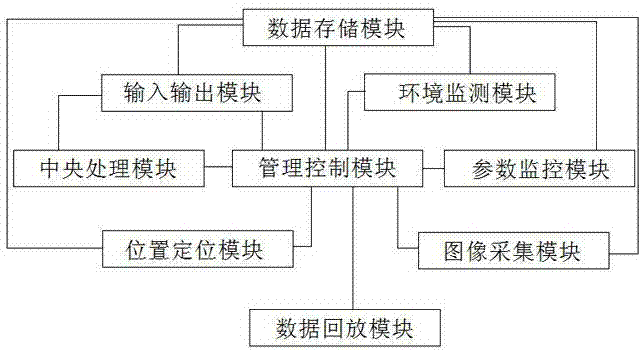

[0014] Such as figure 1 The welding management system of a plastic pipe hot-melt welding machine includes a central processing module, an environmental monitoring module, an input and output module, a parameter monitoring module, a position positioning module, an image acquisition module, a data storage module, a data playback module, and a management control module. module; before welding, the operator inputs welding-related data into the data storage module through the input and output module, and automatically monitors the longitude, latitude and height values of the position through the position positioning module, and monitors the humidity, temperature, and height of the welding operation site in real time through the environmental monitoring module The value of the air pressure, and these values are transmitted to the central processing module through the management control module, and input to the data storage module for recording, and the central processing module g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com