Finished hybrid power automobile torque distribution system and method based on parallel control

A hybrid electric vehicle, vehicle torque technology, applied in hybrid electric vehicles, motor vehicles, control devices, etc., can solve problems such as strong coupling, inability to adjust controller parameters, low average load rate of the engine and low fuel utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the drawings.

[0037] 1. System composition

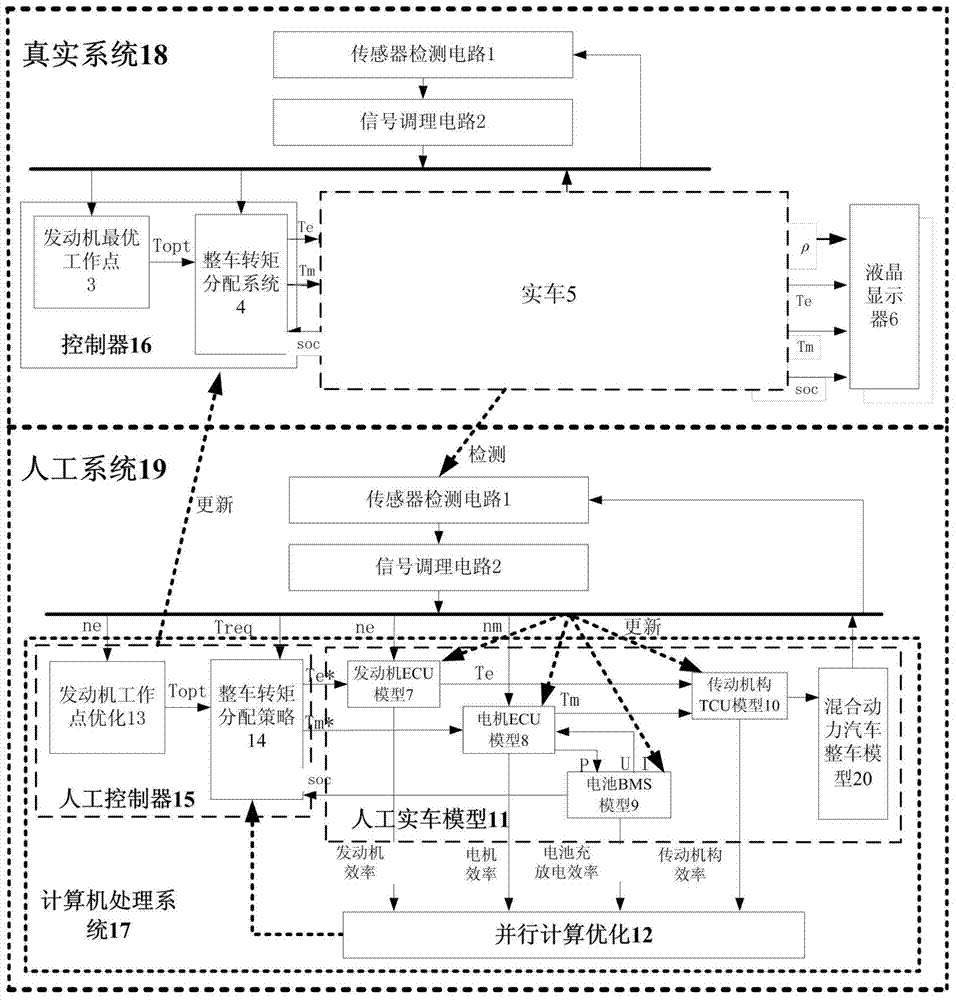

[0038] Such as figure 1 As shown, the hybrid vehicle torque distribution system based on parallel control of the present invention includes two parts: a real system 18 and an artificial system 19; the real system 18 is composed of a sensor detection circuit 1, a signal conditioning circuit 2, a controller 16, and a liquid crystal display 6. The controller 16 includes two parts: the engine optimal operating point module 3 and the vehicle torque distribution system 4; the manual system 19 is composed of a sensor detection circuit 1, a signal conditioning circuit 2, a computer processing system 17, and the computer processing system 17 is composed of The manual controller 15, the manual actual vehicle model module 11, and the parallel computing optimization module 12. The manual controller 15 includes the engine operating point optimization module ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com