Silo top slip-form lifting construction method adopting spatial horizontal supporting system

A technology of horizontal support and construction method, which is applied in the direction of formwork/formwork/work frame, preparation of building components on site, building type, etc., which can solve the problems of insufficient bearing capacity of steel pipe truss structure and inability to get rid of it, so as to shorten the construction period , cost saving, clear force transmission effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

[0025] In order to clearly illustrate the construction method of the present invention, at first refer to Figure 1-3 Explain the spatial horizontal support system built during the construction process.

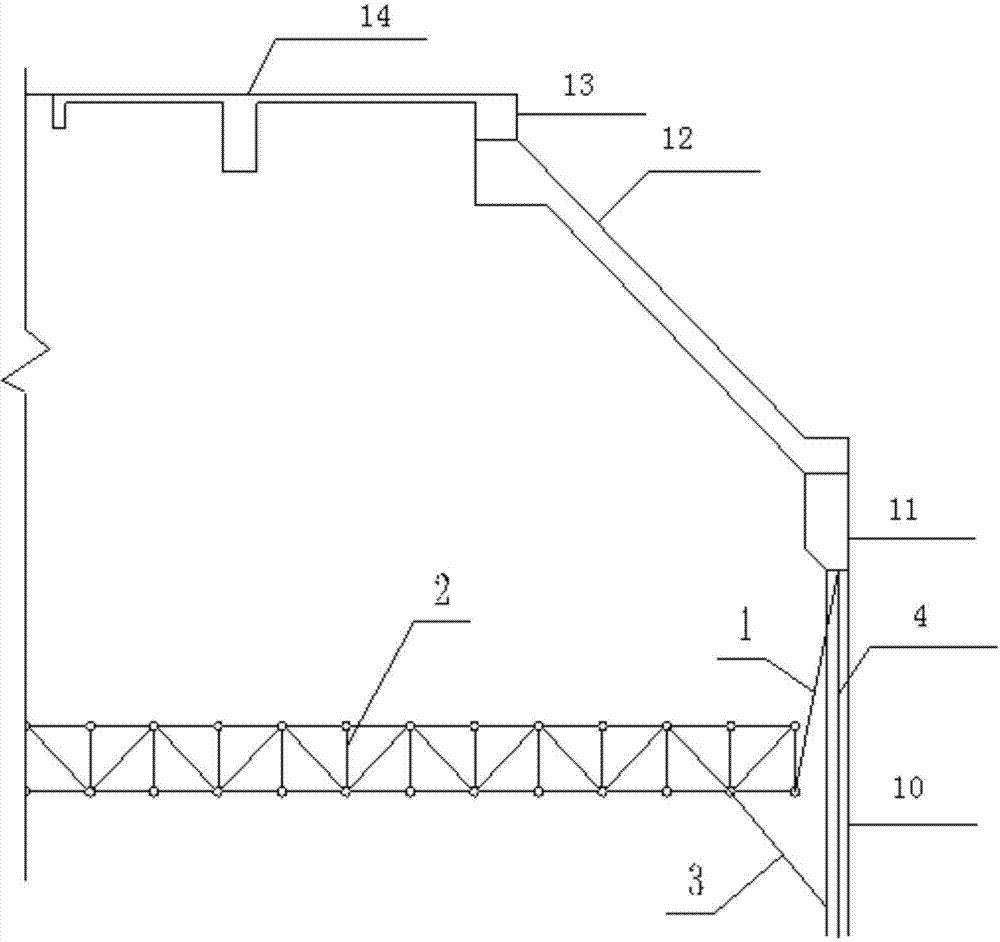

[0026] After the silo roof is constructed, it includes a large ring beam 11, an inclined cone shell 12, a small ring beam 13 and a platform beam plate 14. The silo roof steel pipe truss support system adopted in the present invention mainly includes multiple Steel wire rope 1, steel pipe truss 2, and lower support 3 several parts.

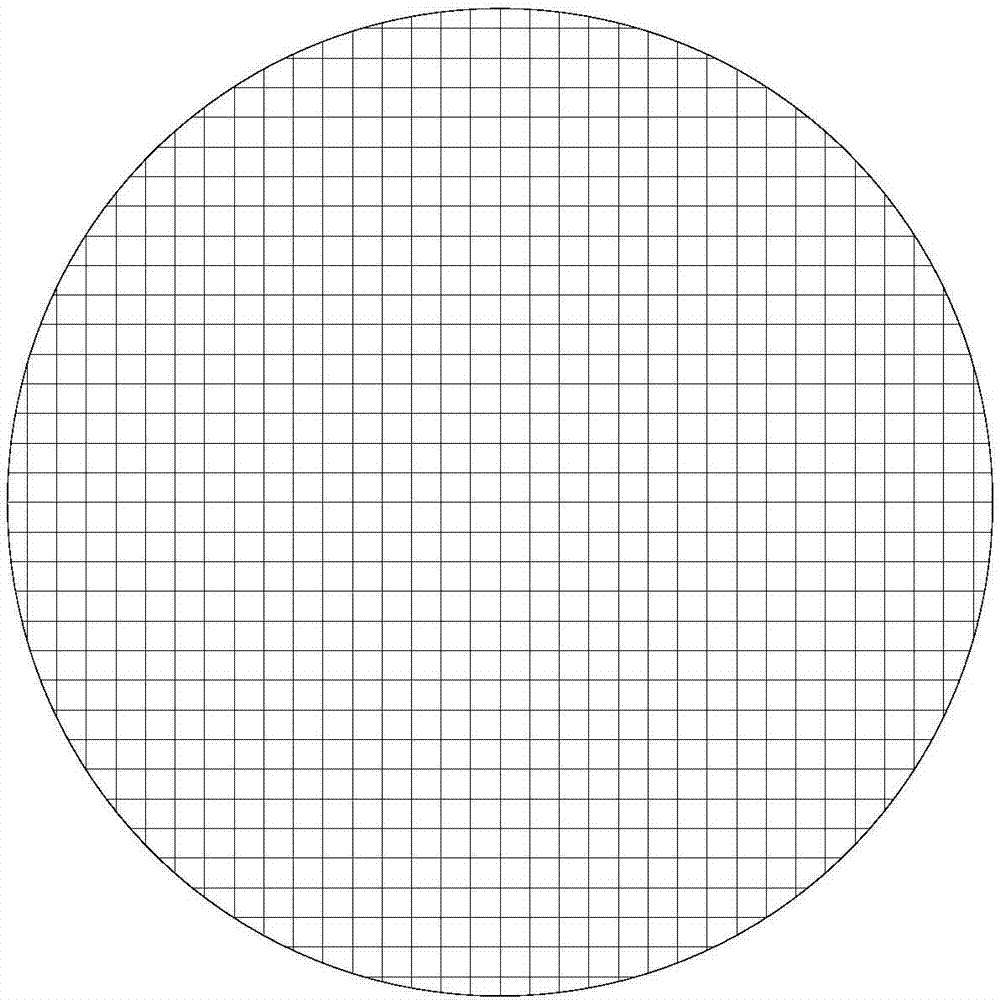

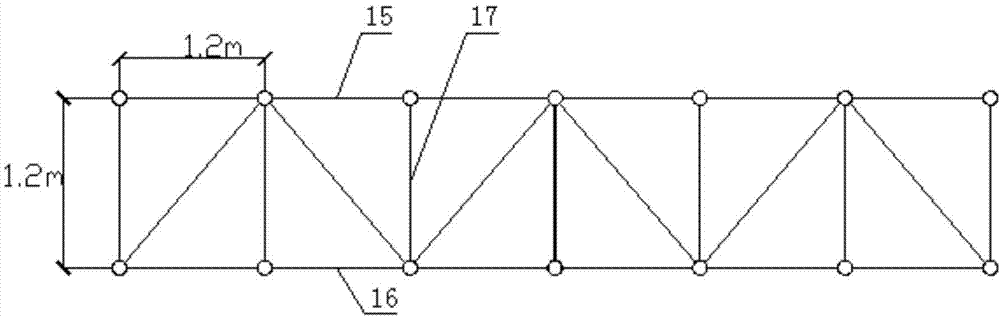

[0027] Steel pipe truss 2 is a space bar system formed by ordinary building scaffolding steel pipes and fasteners. It is an orthogonal space truss structure composed of a series of plane trusses, and its form is circular. The lengths of the upper chord 15 and the lower chord 16 of the steel pipe truss 2 are both 1.2m, and the hei...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap