Cooling fin suitable for high-power LED lamp heat radiator

A technology of LED lamps and heat sinks, applied in lighting and heating equipment, cooling/heating devices of lighting devices, lighting devices, etc., can solve the problem of junction temperature affecting the service life of LED lamps, shortening the life of LED lamps, restrictions on use and promotion, etc. problems, to achieve the effect of lowering the temperature, increasing the number, and intuitive structure and shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0025] The present invention is applicable to the heat sink of the high-power LED lamp heat sink, and a plurality of branch heat sinks are drawn out from the heat sink of the traditional heat sink. Traditional radiators choose round radiators or rectangular radiators.

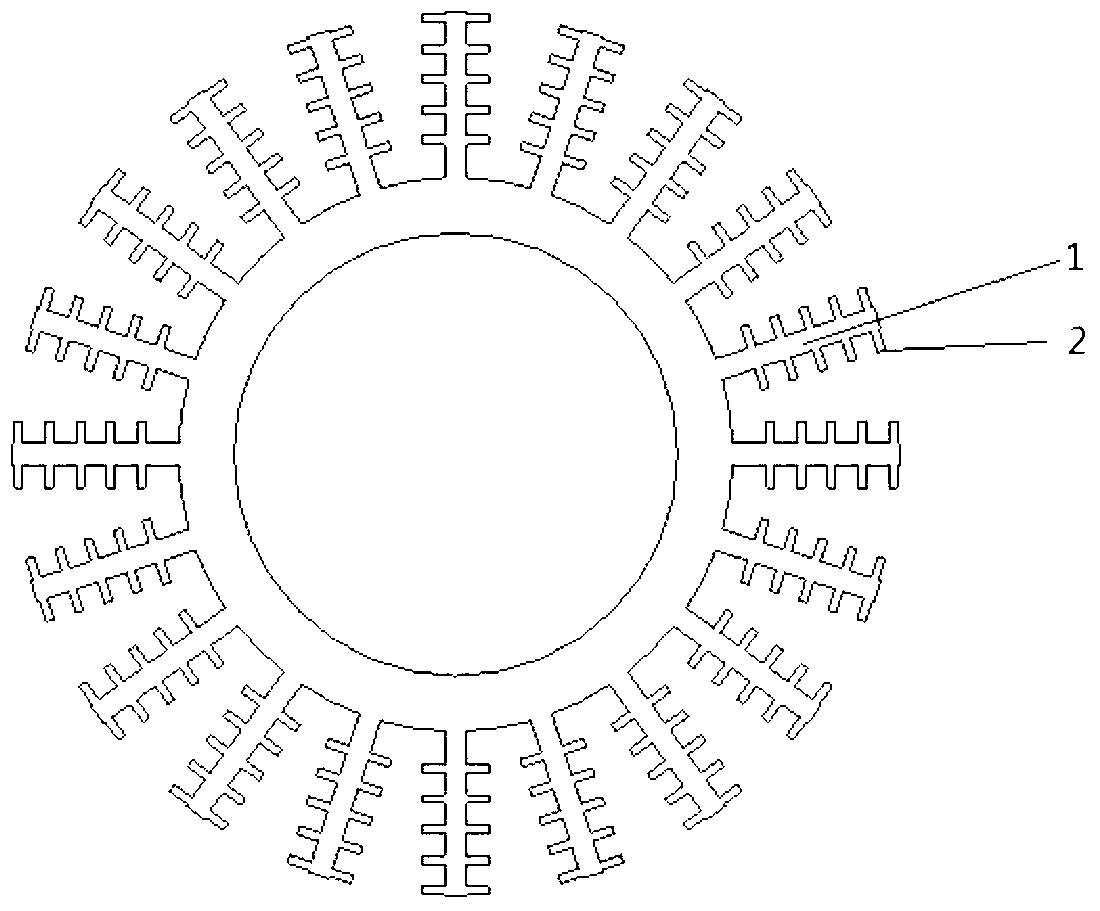

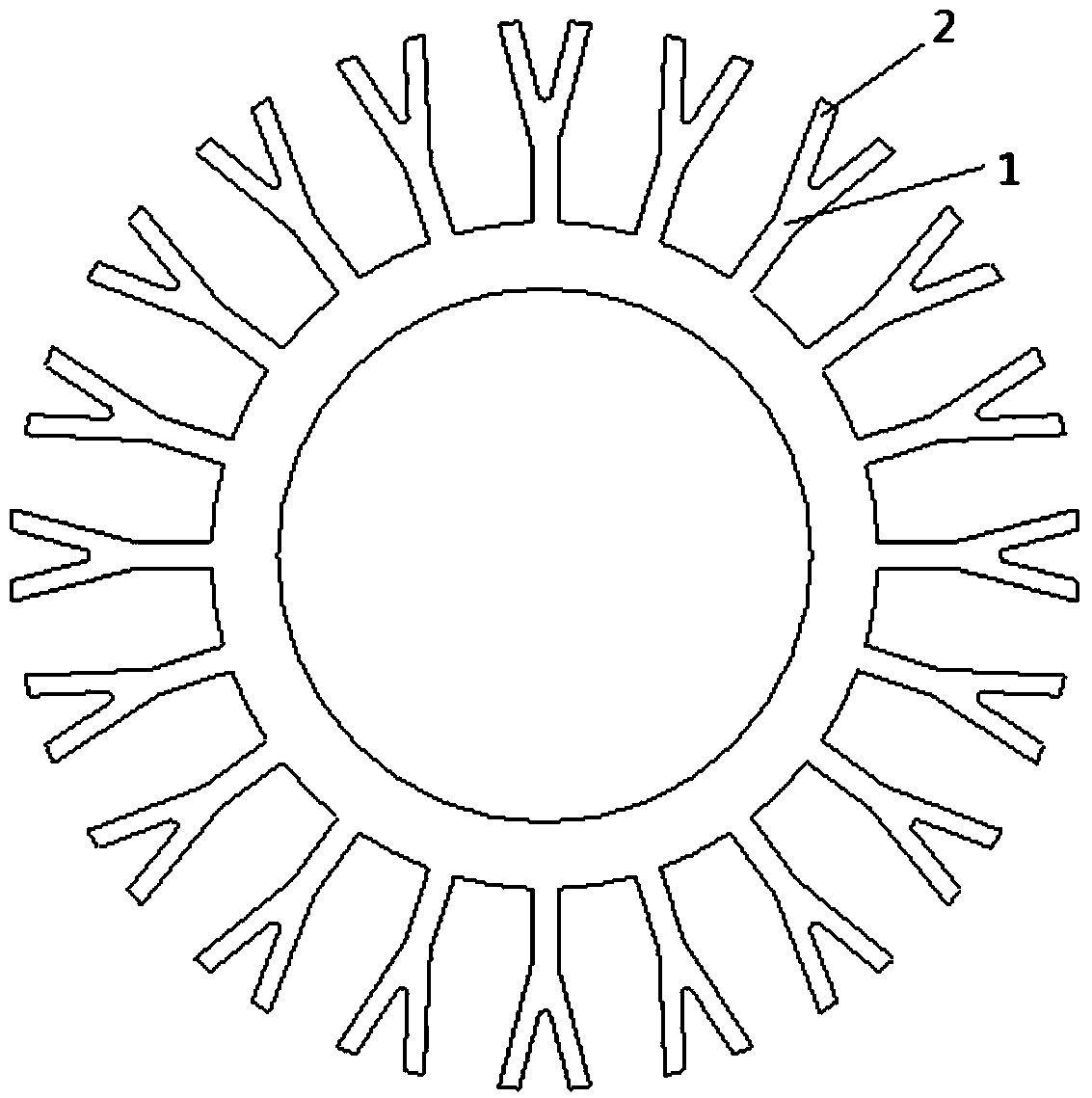

[0026] see figure 1 and image 3 , when a circular radiator is adopted, the present invention includes a plurality of trunk fins 1 evenly arranged in the circumferential direction of the radiator body; each trunk fin 1 is evenly arranged with a plurality of branch fins 2, and the radiator body is Cylindrical structure.

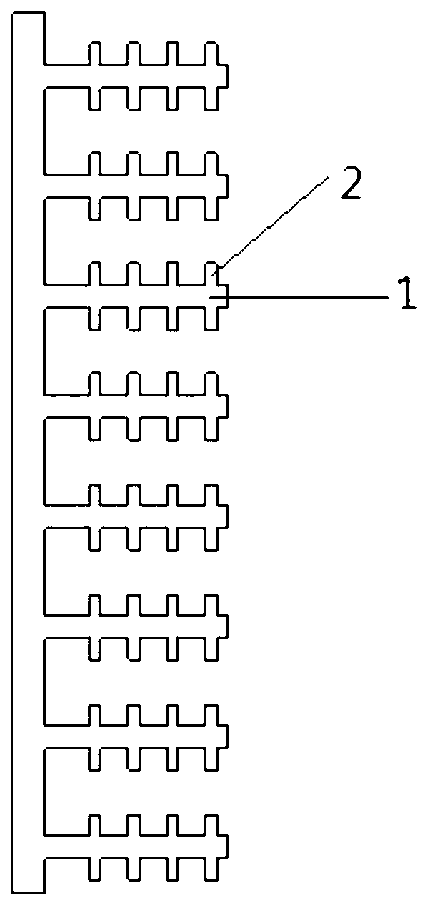

[0027] see figure 2 and Figure 4 , when a rectangular radiator is used, the present invention includes a plurality of trunk fins 1 vertically arranged on the radiator body; a plurality of branch fins 2 are evenly arranged on each trunk fin 1, and the radiator body is a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com