Device and method for detecting size of silicon briquette

A technology for size detection and silicon blocks, applied in measuring devices, optical devices, instruments, etc., can solve problems such as chipping of silicon blocks, achieve the effects of reducing cost losses, reducing labor intensity, and avoiding errors or reading errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

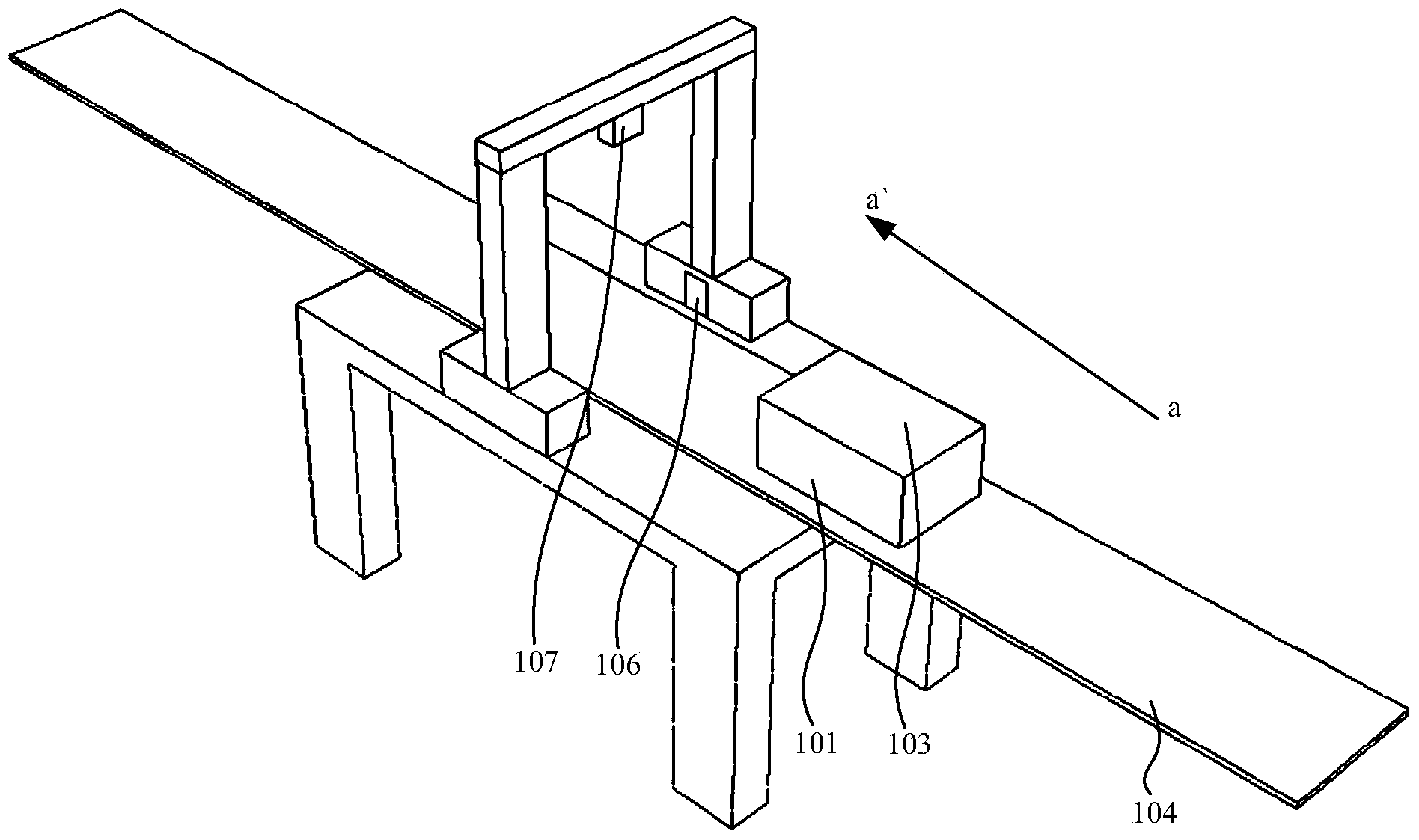

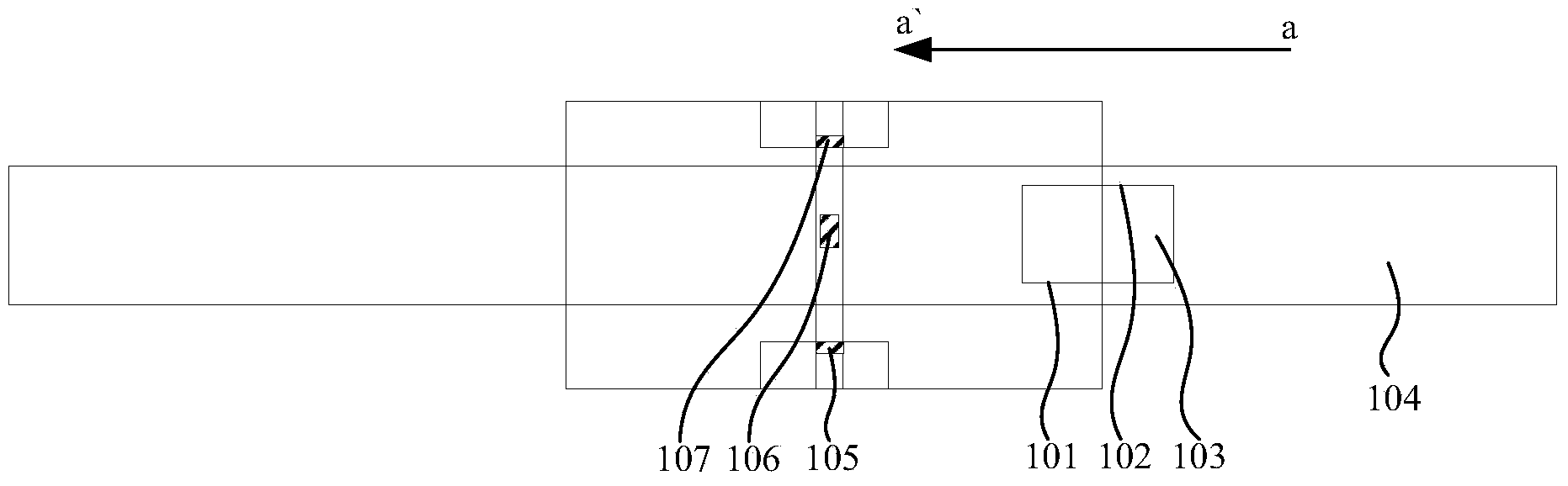

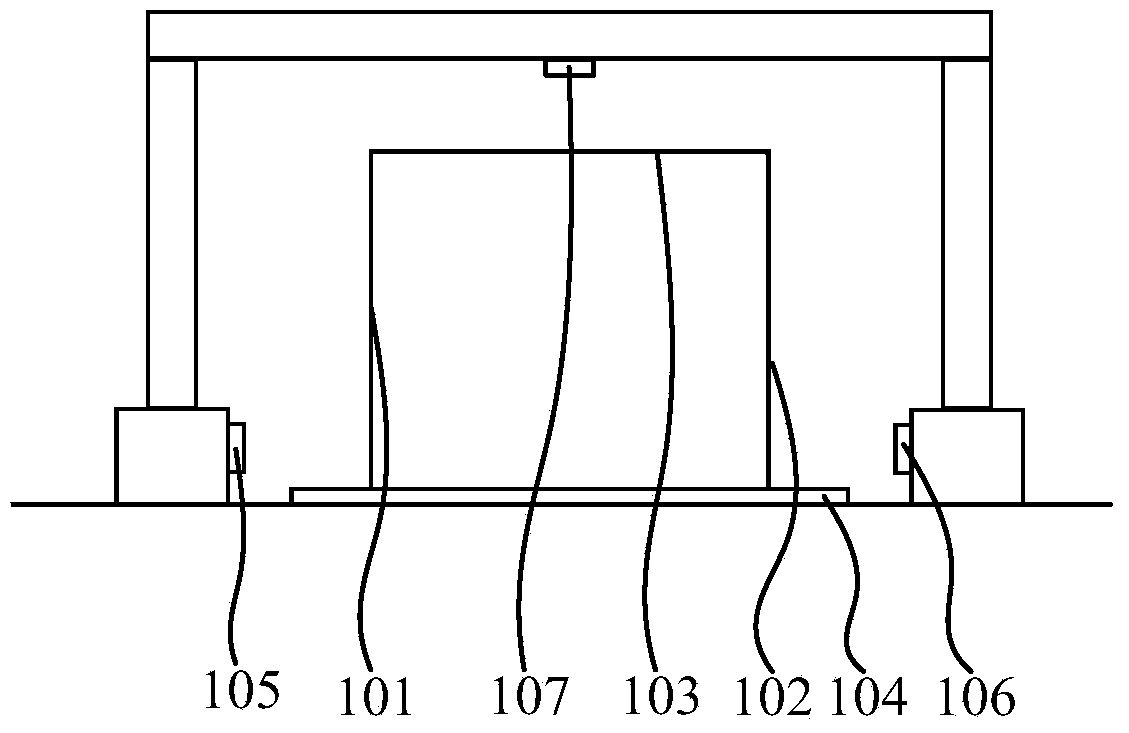

[0035] This embodiment provides a silicon block size detection device, combined with such figure 1 , figure 2 and image 3 As shown, the silicon block size detection device includes: a first laser generator 105, a second laser generator 106, a third laser generator 107 and a processor (not shown in the figure).

[0036] Wherein, the first laser generator 105 is arranged on the left side of the conveyor belt 104, and the laser light emitted by it is perpendicular to the first surface 101 of the silicon block;

[0037] The second laser generator 106 is arranged on the right side of the conveyor belt 104, and the laser light emitted by it is perpendicular to the second surface 102 of the silicon block;

[0038] The third laser generator 107 is arranged above the conveyor belt 104, and the laser light emitted by it is perpendicular to the third surface 103 of the silicon block;

[0039] The processor is respectively connected with the first laser generator 105 , the second las...

Embodiment 2

[0063] This embodiment provides a silicon block size detection method, which is applied to the silicon block size detection device described in Embodiment 1, and the method includes the following steps:

[0064] Step S1: Place the silicon block on the conveyor belt so that the laser emitted by the first laser generator is perpendicular to the first surface of the silicon block, the laser emitted by the second laser generator is perpendicular to the second surface of the silicon block, and the third The laser emitted by the laser generator is perpendicular to the third surface of the silicon block;

[0065] In this embodiment, the conveyor belt keeps moving in one direction. After the silicon block is placed on the conveyor belt, the placement position of the silicon block needs to be manually or mechanically adjusted so that the laser light emitted by each laser generator is perpendicular to the respective corresponding laser beams. surface of the silicon block.

[0066] In t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com