Automation detection device of vibration screen I-shaped beam

An automatic detection and I-shaped screening technology, which is applied in the direction of measuring devices, measuring instrument components, instruments, etc., can solve the problems of inability to realize automation, achieve the effects of reducing manual labor, good motion stability, and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

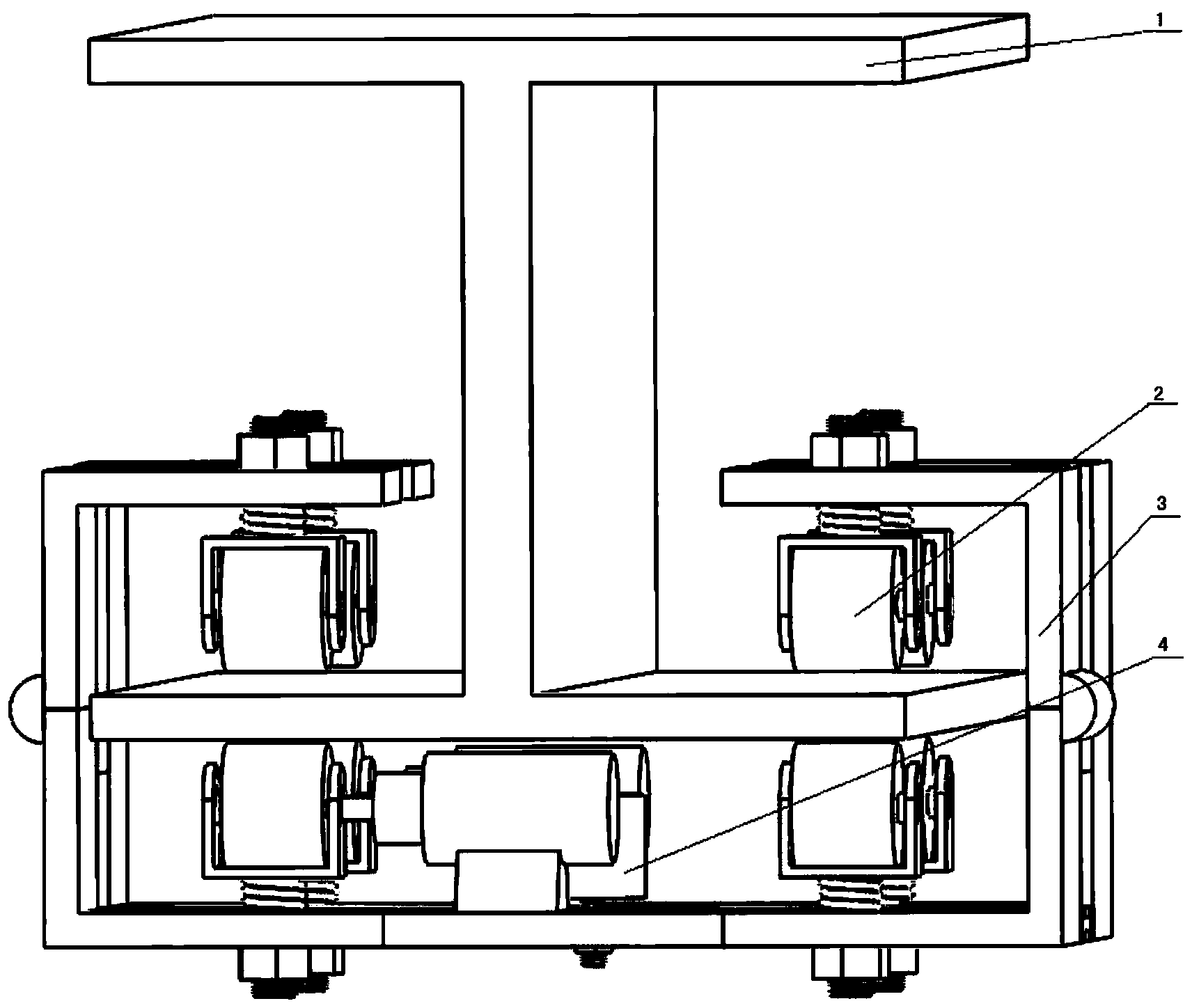

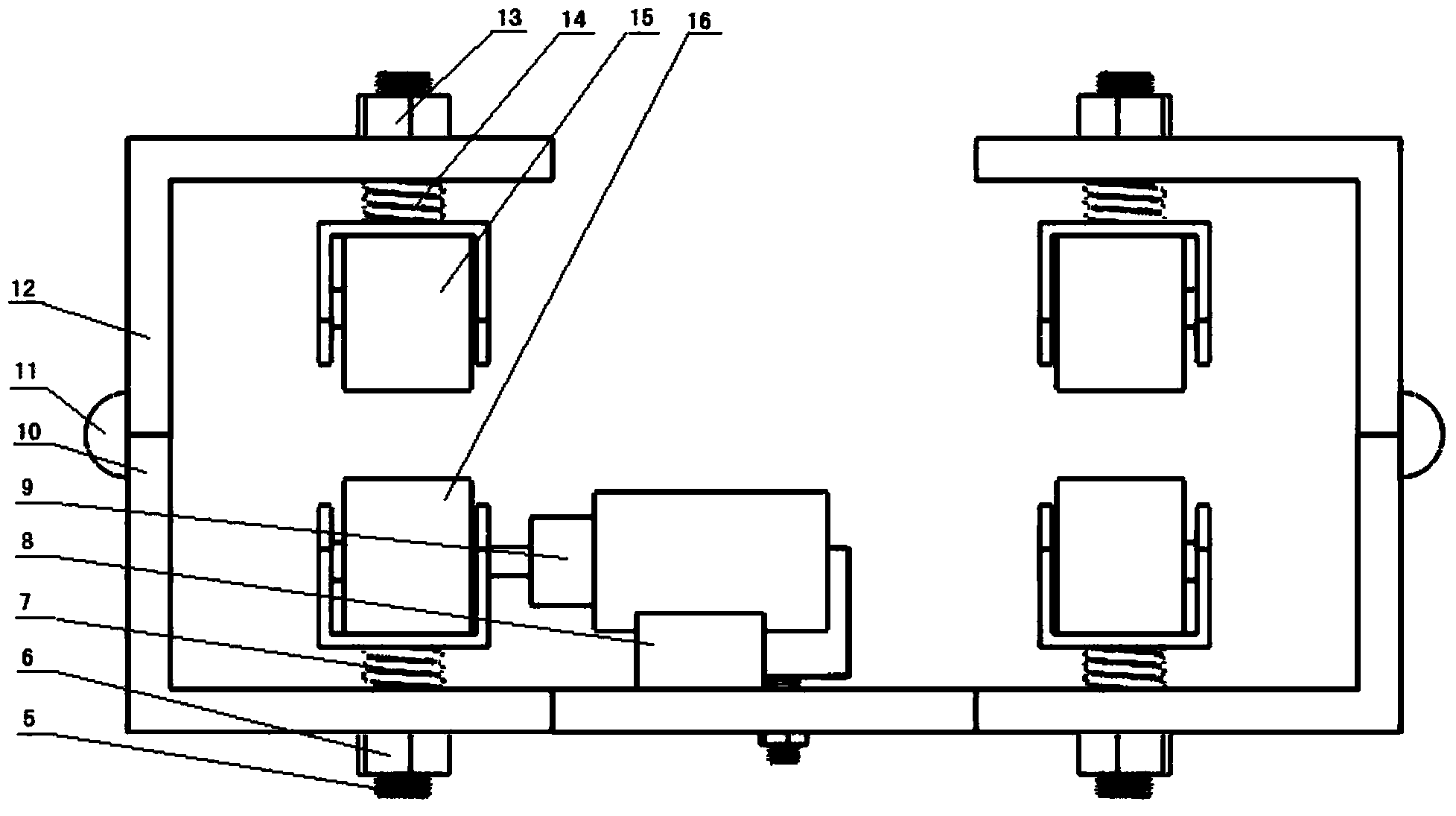

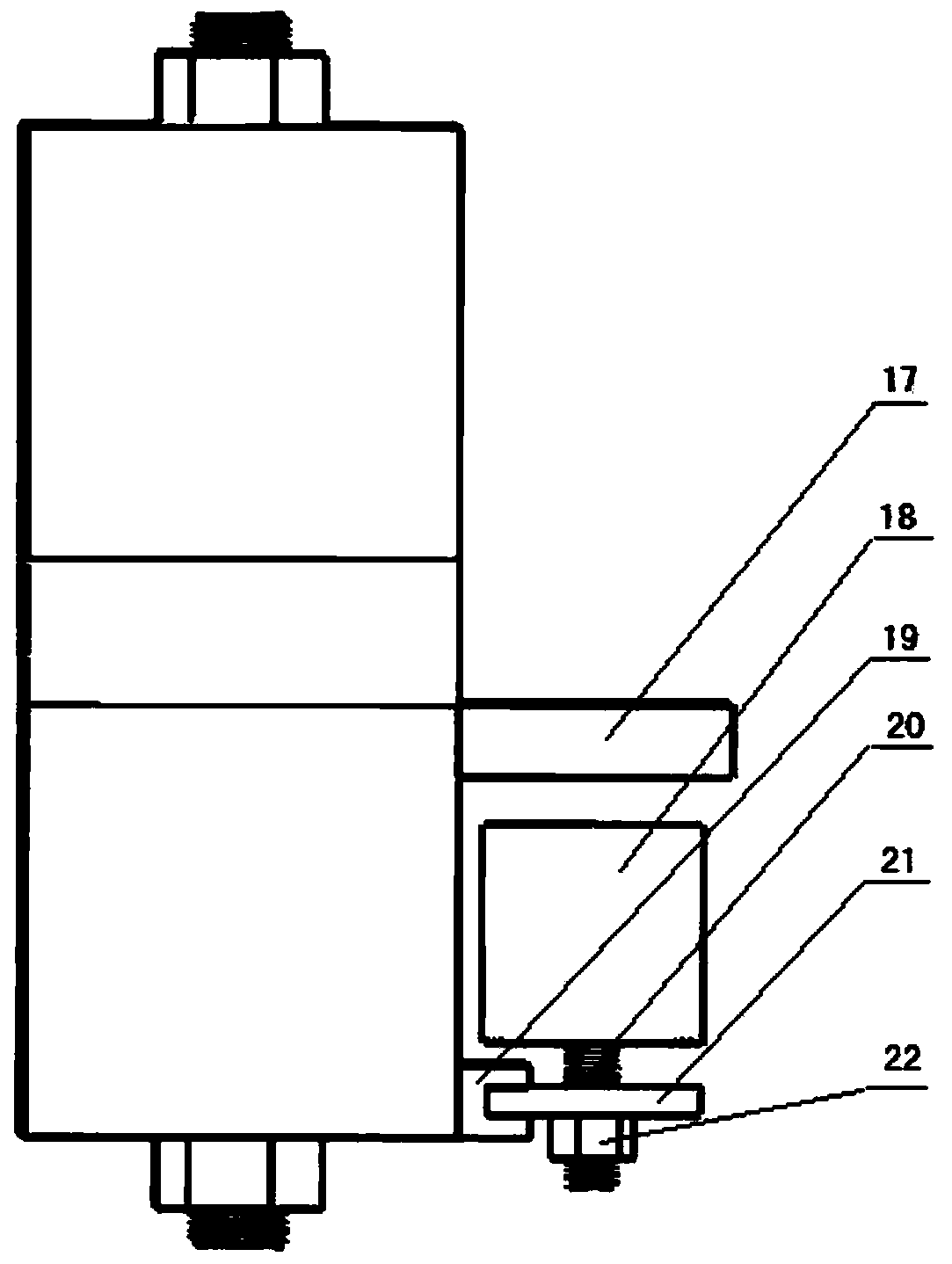

[0014] The present invention will be further described below in conjunction with accompanying drawing.

[0015] like Figure 1-3 , an automatic detection device for an I-shaped beam of a vibrating screen, the device includes a motion system 2, a body 3, and a slewing system 4, and the I-shaped beam 1 is a component to be detected; the device solves the need for automatic detection of the beam The shortcomings of manual inspection and inability to realize automation have significantly improved the inspection efficiency and inspection quality of the girder.

[0016] In order to achieve the above purpose, the technical solution adopted by this device is an automatic detection device for the I-shaped beam of the vibrating screen. The motion system of the device is composed of an active traveling mechanism and a driven traveling mechanism. The active traveling mechanism includes a motor 9, a motor base 8. Driving wheel 16, spring a7, nut a6; driven traveling mechanism includes dri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com