Novel all-medium armor optical cable

An armored optical cable, all-dielectric technology, applied in the field of new all-dielectric armored optical cable, can solve the problems of metal bending affecting cable performance, weak ability to protect optical fiber, easy to be attacked by lightning, etc., to avoid lightning accidents, strong optical fiber capability, The effect of strong crushing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

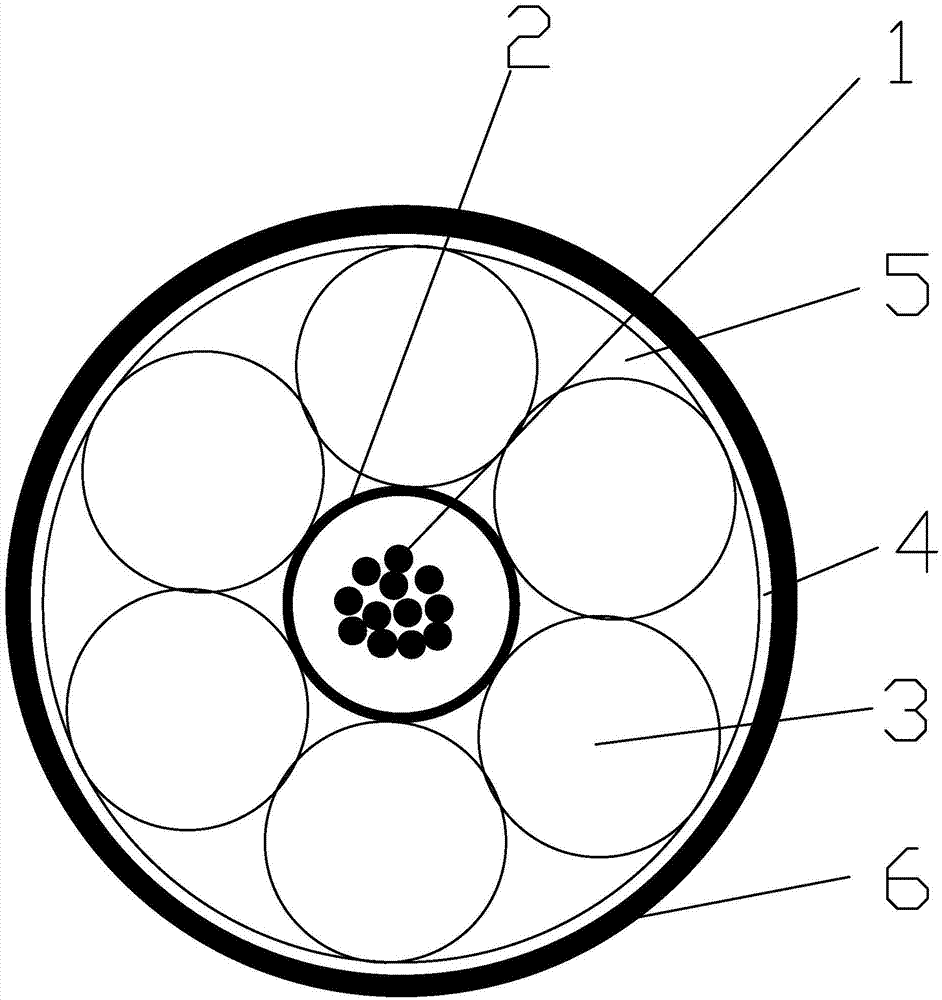

[0013] refer to figure 1 , the present invention includes a plurality of colored optical fibers 1, the optical fibers 1 are coated with a bundle tube 2, a number of non-metallic round rods 3 are arranged around the bundle tube 2 in sequence, and the non-metallic round rods 3 are covered with a non-metallic longitudinal tape 4. A water-blocking layer 5 is filled between the non-metallic longitudinal tape 4 and the beam tube 2 and the non-metallic round rod 3 , and the non-metallic longitudinal tape 4 is covered with a sheath 6 .

[0014] In this embodiment, the optical fiber is a colored optical fiber, which is convenient to use.

[0015] In the structure of the present invention, the layer-twisted type is changed to the central tube type, which i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com