System and method for controlling operation of flotation industrial process under dual-network environment

An industrial process and environmental technology, applied in the direction of comprehensive factory control, comprehensive factory control, electrical program control, etc., can solve problems such as the impact of system economic indicators tracking performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

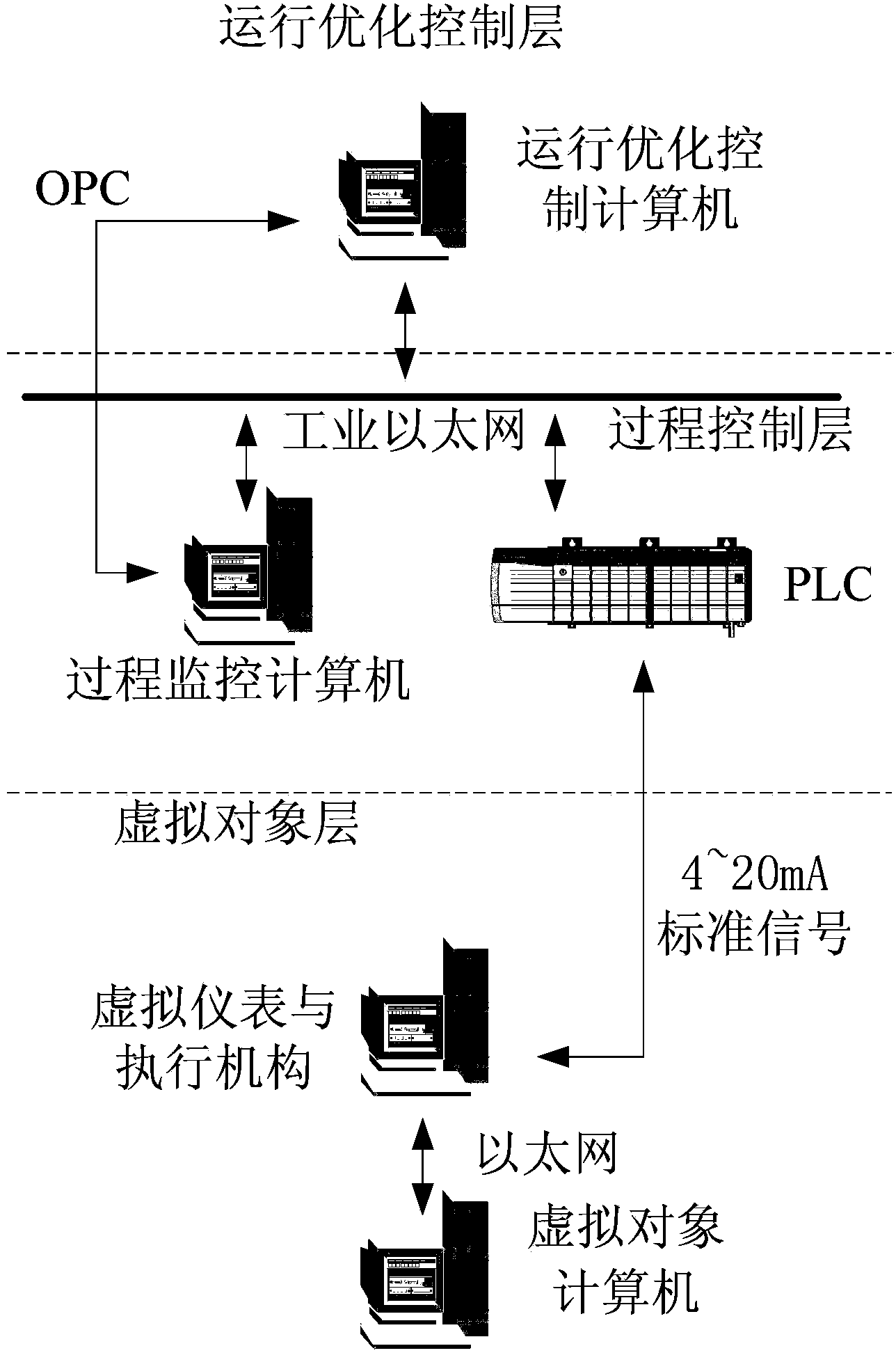

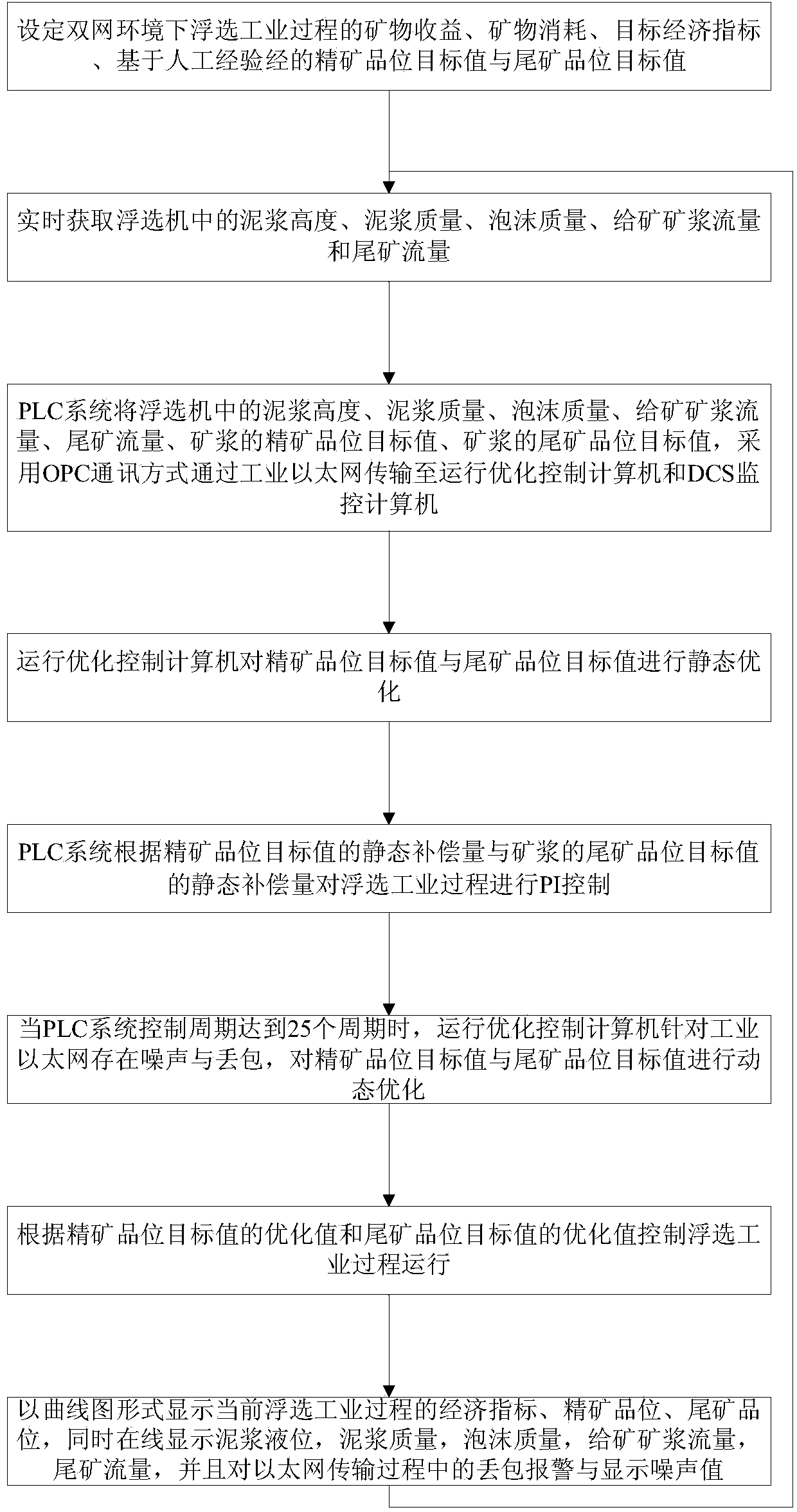

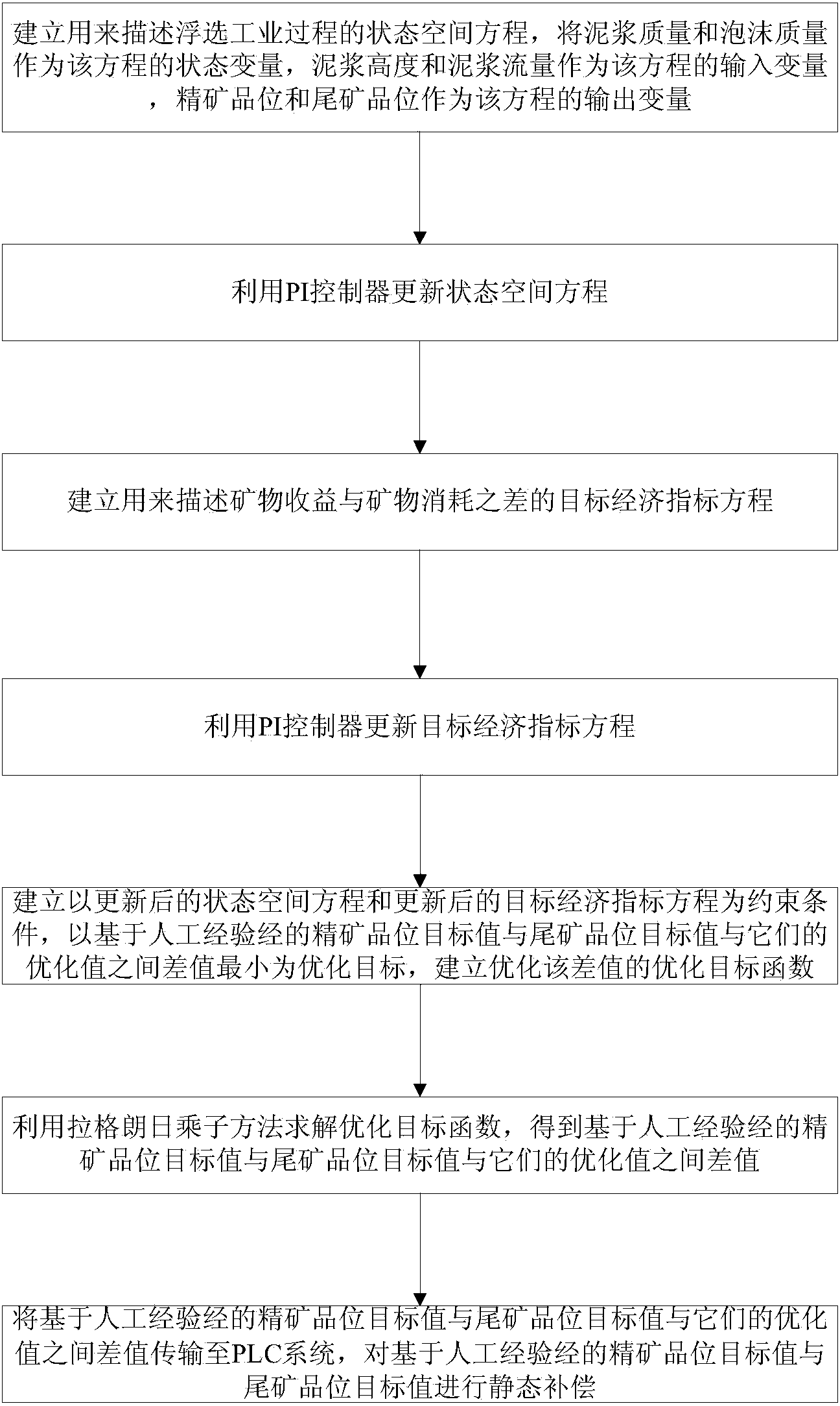

[0047] The industrial process of flotation is a three-layer control structure, which is composed of operation optimization control layer, process control layer and flotation process layer, such as figure 1 As shown, in this embodiment, the flotation process layer can be realized by hardware-in-the-loop simulation experiments, and the virtual object layer is the simulated virtual flotation process. Operation optimization control layer: Operation optimization control layer includes operation optimization control computer, which reads the current working conditions from the process control PLC through industrial Ethernet, and then uses the dual-network operation layer algorithm to give the optimal underlying control setting value. The process control layer includes PLC, which mainly realizes the underlying control functions, as wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com