Vehicle-glass cleaning fluid composition comprising anionic surfactant and tartaric acid

A surfactant and automotive glass technology, applied in the preparation of anionic surface active compounds, detergent compositions, detergent mixture compositions, etc., can solve the problem of polluting painted surfaces, noise or wear of wiper blades, and blocking drivers Achieve excellent corrosion resistance, reduce weight change, and improve abnormal changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example

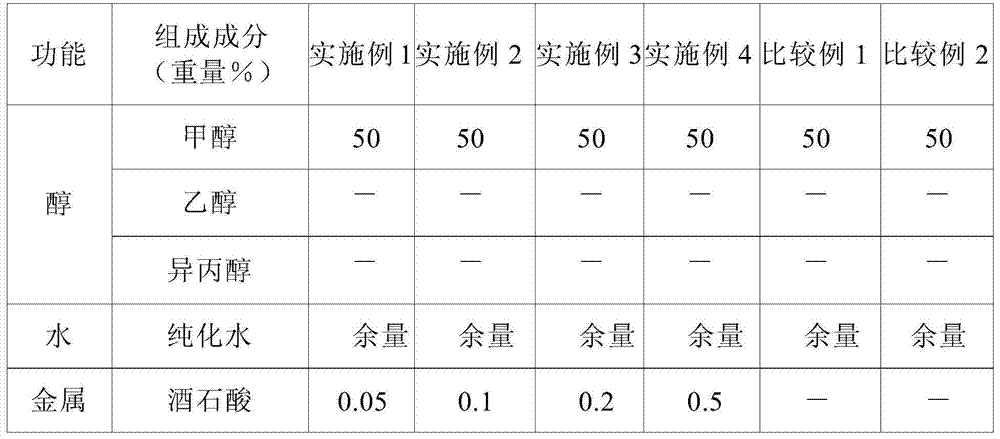

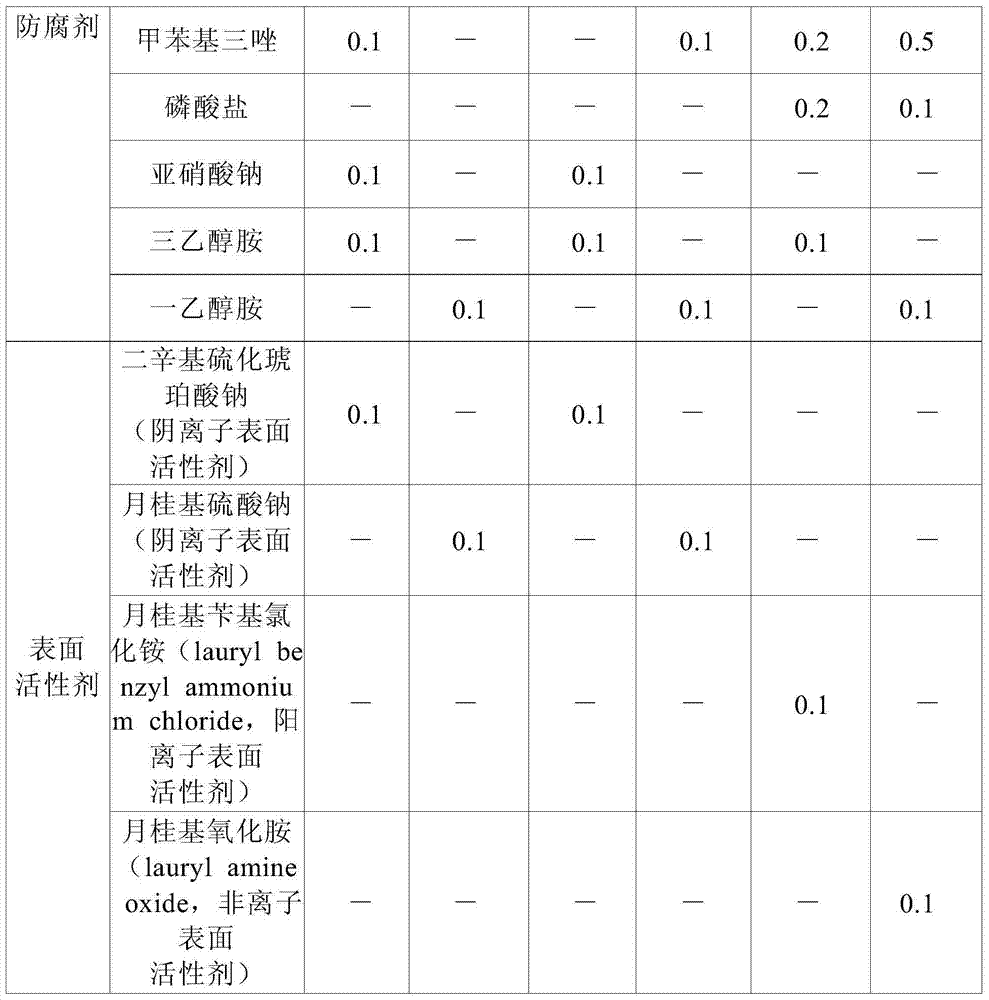

[0041] According to the composition in Table 1 below, the automobile glass washer liquid composition of the present invention was prepared.

[0042] Table 1

[0043]

[0044]

[0045] According to the composition of Table 1, the automobile glass cleaning liquid composition of embodiment and comparative example were prepared respectively. At this time, each component was stirred and mixed at normal temperature (25° C.) for 1 hour, and filtered by a high-precision filtration method (10 μm) to prepare.

experiment example

[0047] Carry out the cleaning test of metal corrosion test, coating film influence test, rubber influence test, plastics influence test, wiper blade to the composition (table 1) of the automobile glass cleaning liquid embodiment of above-mentioned experimental example and comparative example And noise generation test, to carry out performance evaluation, the results are shown in Table 2 to Table 4 below.

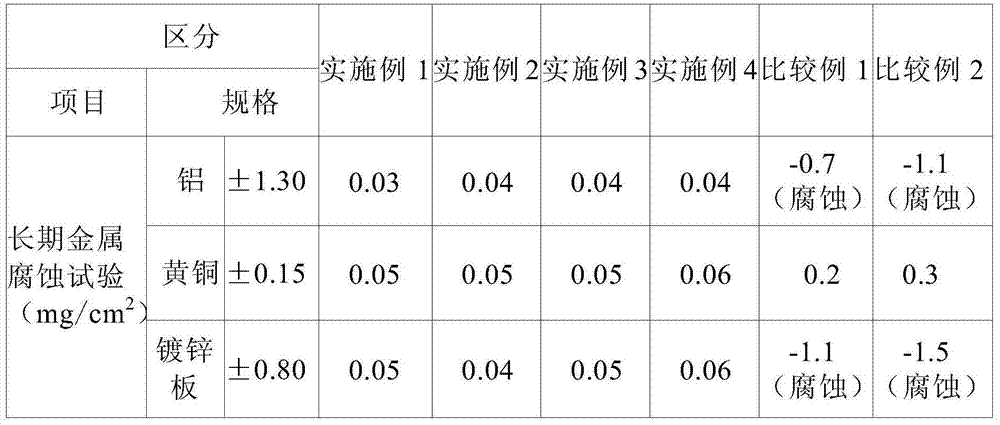

[0048] Table 2

[0049] Long-term metal corrosion test based on composition content (50°C×120 hours (hr))

[0050]

[0051] In order to evaluate the superiority of the car glass washer fluid with respect to long-term durability, the following tests were carried out. The metal corrosion test was carried out according to KS M2163 standard, and the result was observed after 120 hours at a temperature of 50°C.

[0052]The above-mentioned measurement results are shown in Table 2, and it can be confirmed that the long-term corrosion resistance evaluation results show that the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com