Common rail system, internal combustion engine, and device and method for controlling and/or regulating an internal combustion engine

A common rail system and internal combustion engine technology, applied in the field of common rail system, can solve the problems of inaccuracy, inaccuracy and inaccuracy of internal combustion engine fuel quantity, etc., and achieve the effect of efficient data function, reliable evaluation or association

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

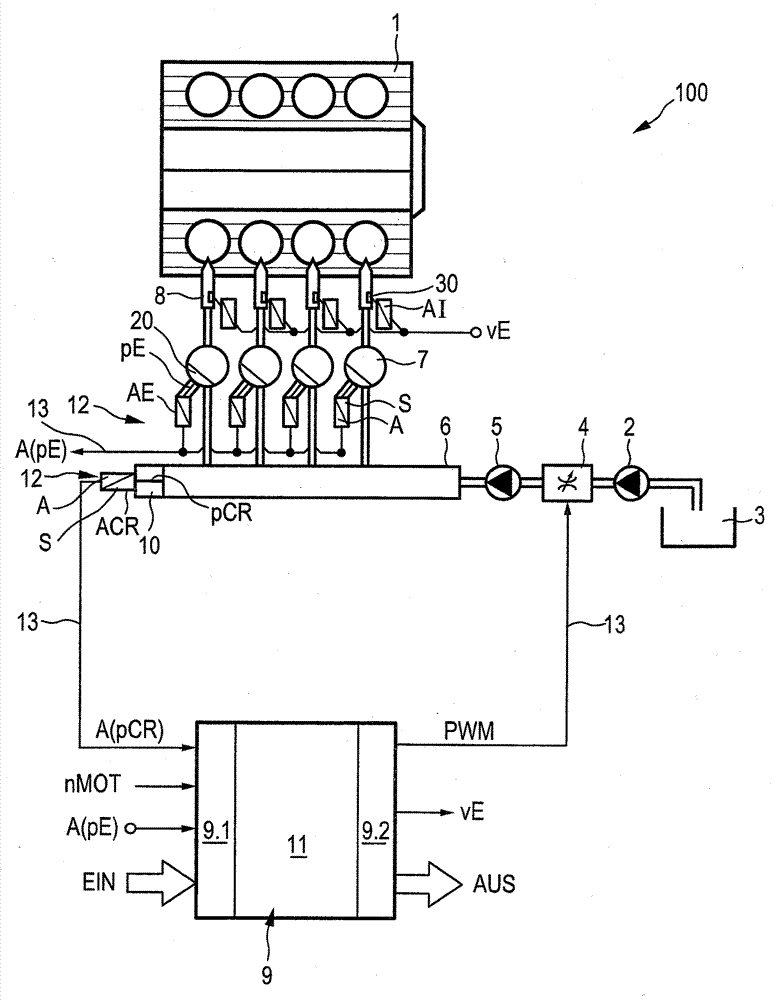

[0018] figure 1 By way of example, a common rail system 100 with an electronically controlled internal combustion engine 1 is shown, which is designed substantially similarly to DE 10 2006 034 515 B3 mentioned at the outset. The common rail system 100 comprises a low-pressure pump 2 for delivering fuel from a fuel tank 3 , a suction throttle valve 4 for determining the volume flow, a high-pressure pump for first delivering fuel into a rail 6 in the event of a pressure increase 5. The fuel is fed further from the rail 6 into a single accumulator 7 provided for each cylinder of the internal combustion engine 1 for the temporary storage of prestressed fuel, and finally further into the injector 8 for injecting the fuel Injection into the cylinder block or combustion chamber of the internal combustion engine 1 .

[0019]In the system shown here, the fuel is sufficiently prestressed in the single accumulator 7 to ensure sufficient injection into the combustion chamber of the inte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com