A forklift hydraulic system with double pump oil supply and energy recovery

An energy recovery and hydraulic system technology, applied in the hydraulic field, can solve the problems of increased system energy consumption, large pressure loss, and large system energy consumption, and achieve the effects of reduced system energy consumption, small pressure loss, and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

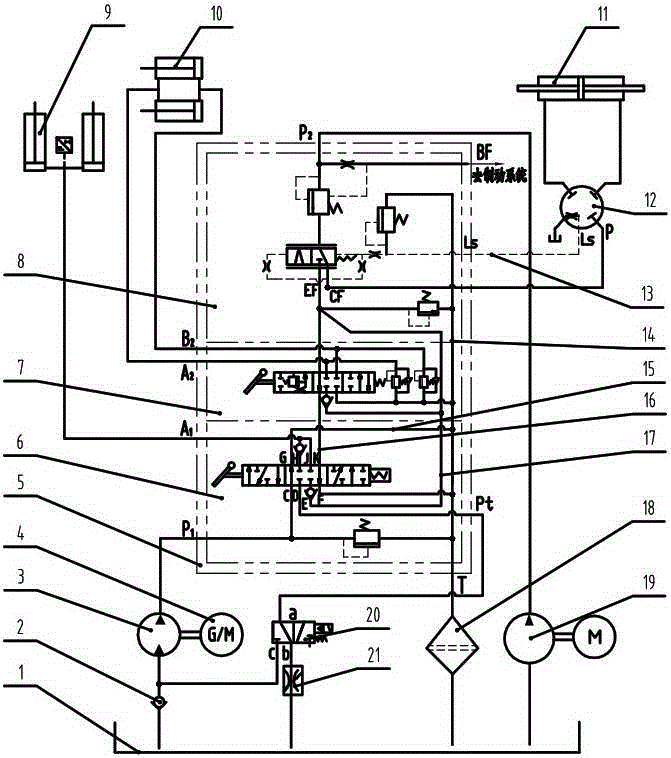

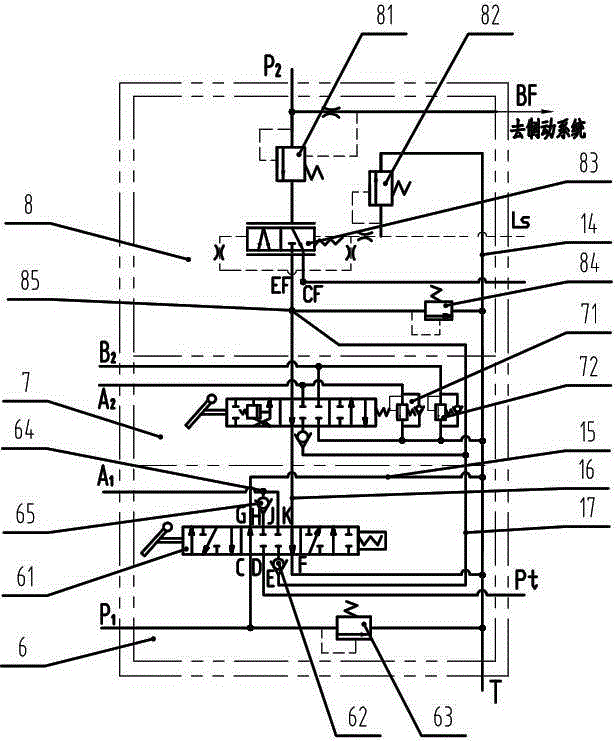

[0022] see figure 1 and figure 2 , a forklift hydraulic system with double-pump oil supply and energy recovery includes a fuel tank 1, a first oil pump 3, a motor 4, a multi-way valve 5, two lifting cylinders 9, two tilting cylinders 10, a steering cylinder 11, and a load sensor Steering gear 12, oil filter 18, second oil pump 19, directional control valve 20, speed limiting valve 21, the components are connected by pipelines; The valve plate 7 and the oil inlet valve plate 8 are composed of a multi-way valve; the oil inlet and return valve plate 6 is provided with a three-position eight-way lifting reversing valve 61 and a first main safety valve 63; the tilting reversing valve The direction valve section 7 includes an inclined three-position six-way reversing valve, a first overload supplement valve 71 and a second overload supplement valve 72; the oil inlet valve section 8 includes a diverter valve 81, a priority valve 83, and a steering safety valve 82 And the second ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com