Road well lid produced by utilizing waste residue and production method thereof

A technology of waste slag and manhole cover, which is applied in the field of road manhole cover made of waste slag and its preparation, which can solve the problems of poor wear resistance, aging resistance and chemical corrosion resistance, fast decay of bearing capacity, and easily broken manhole cover. Simple and easy to implement, good compressive and flexural strength, and the effect of avoiding theft and loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A road manhole cover made of waste slag is characterized in that it is composed of the following raw materials in terms of weight percentage: 50% of waste slag, 20% of quartz sand, and 20% of 500-grade cement.

[0029] The waste slag refers to the waste rock produced during the mining and processing of mineral resources.

[0030] Raw material requirements

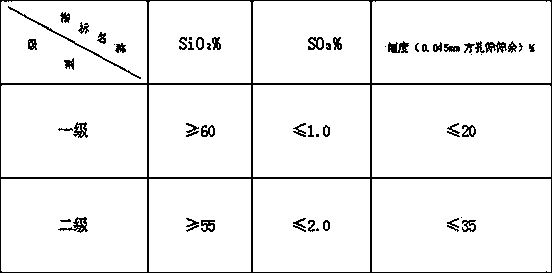

[0031] (1) Main technical indicators of waste residue

[0032]

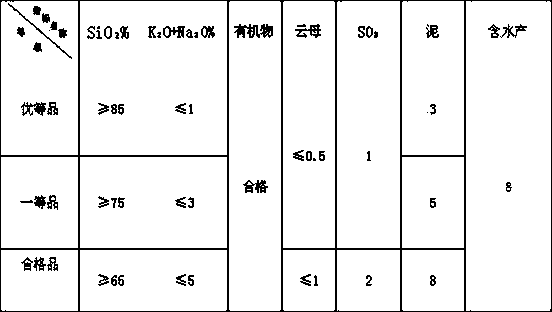

[0033] (2) Main technical indicators of quartz sand

[0034]

[0035] According to the percentage content of the above raw materials, waste residue: square hole sieve with a fineness of 0.049mm, the sieve residue <30%; quartz sand: a square hole sieve with a fineness <2.5mm, and the sieve residue<25%;

[0036] Its preparation steps are:

[0037] (1) Measure the above-mentioned raw materials and 0.12% moisture respectively, and then put them into a forced twin-shaft mixer and mix them into a mixture, and the mixing time is 6 minutes;

[0038] (...

Embodiment 2

[0044] A road manhole cover made of waste slag is characterized in that it is composed of the following raw materials in terms of weight percentage: 55% of waste slag, 25% of quartz sand, and 25% of 500-grade cement.

[0045] The waste slag refers to smelting waste slag.

[0046] The smelting waste slag refers to ferroalloy slag.

[0047] Raw material requirements

[0048] (1) Main technical indicators of waste residue

[0049]

[0050] (2) Main technical indicators of quartz sand

[0051]

[0052] According to the percentage content of the above raw materials, waste residue: square hole sieve with a fineness of 0.049mm, the sieve residue <30%; quartz sand: a square hole sieve with a fineness <2.5mm, and the sieve residue<25%;

[0053] Its preparation steps are:

[0054] (1) Measure the above-mentioned raw materials and 0.12% water respectively, and then put them into a forced twin-shaft mixer to mix and stir to form a mixture, and the stirring time is 6.5 minutes; ...

Embodiment 3

[0061] A road manhole cover made of waste slag is characterized in that it is composed of the following raw materials in terms of weight percentage: 60% of waste slag, 30% of quartz sand, and 30% of 500-grade cement.

[0062] The waste residue refers to other waste residues.

[0063] The other waste residue refers to fly ash.

[0064] Raw material requirements

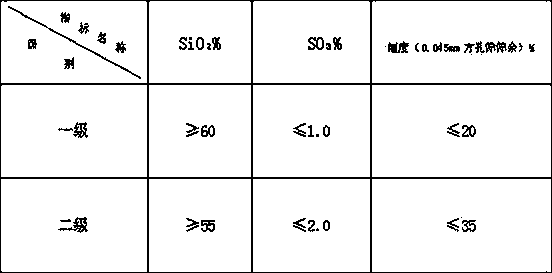

[0065] (1) Main technical indicators of waste residue

[0066]

[0067] (2) Main technical indicators of quartz sand

[0068]

[0069] According to the percentage content of the above raw materials, waste residue: square hole sieve with a fineness of 0.049mm, the sieve residue <30%; quartz sand: a square hole sieve with a fineness <2.5mm, and the sieve residue<25%;

[0070] Its preparation steps are:

[0071] (1) Measure the above-mentioned raw materials and 0.12% moisture respectively, and then put them into a forced twin-shaft mixer to mix and stir to form a mixture, and the stirring time is 7 minutes;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com