Quench hardening shaping fixture for metal-material super-thin opening annular element

A technology for shaping fixtures and metal materials, applied in quenching devices, manufacturing tools, furnace types, etc., can solve the problems of large deformation of the open ring, the opening size of the open ring cannot be guaranteed, etc., to increase the contact area, simple structure, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

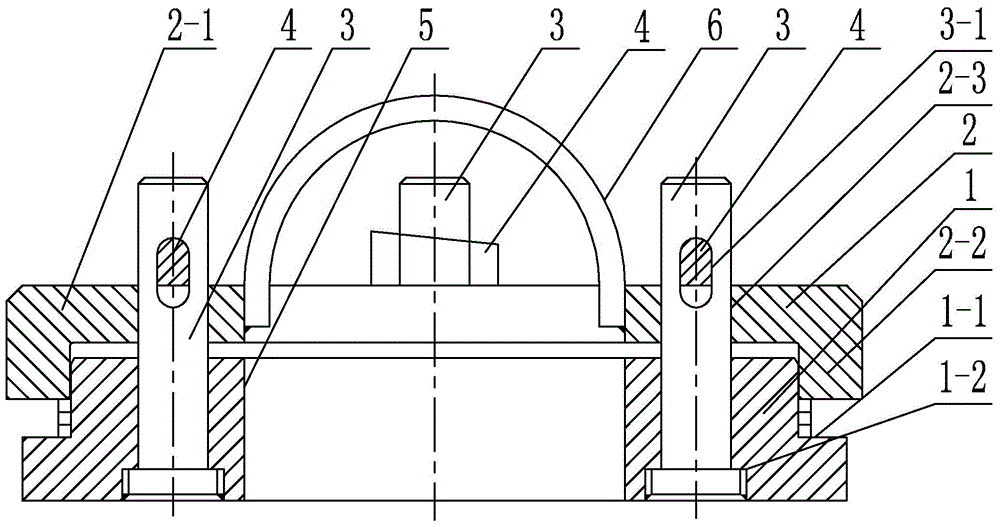

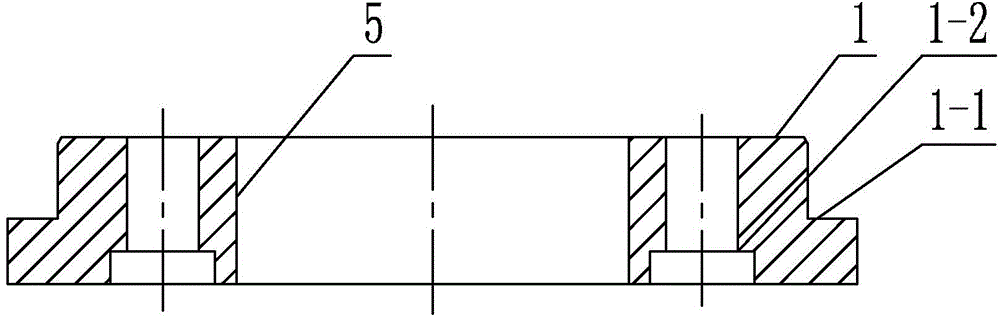

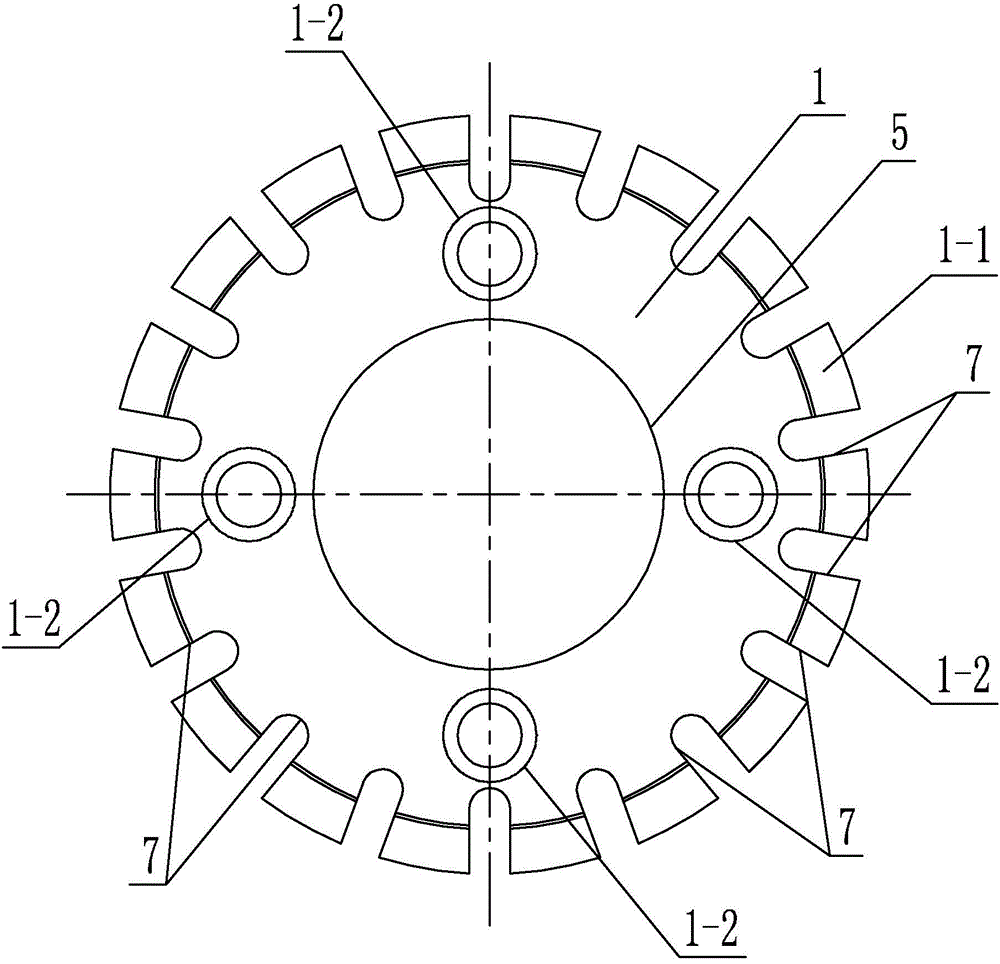

[0013] Specific implementation mode one: as Figure 1~5 As shown, the metal material ultra-thin open ring piece quenching and shaping fixture of this embodiment includes a chassis 1, a pressure plate 2, a hinge 6, a plurality of locking shaft pins 3 and a plurality of wedges 4, and a platform is processed on the chassis 1. Shoulder 1-1, the diameter of the upper part of the chassis 1 is smaller than the diameter of the lower part of the chassis 1, the pressure plate 2 is composed of the pressure plate main body 2-1 and the pressure ring 2-2, the pressure ring 2-2 is fixed on the lower end surface of the pressure plate main body 2-1 On the outer edge and the pressure plate main body 2-1 and the pressure ring 2-2 are integrated, the pressure plate 2 cover is on the upper end surface of the chassis 1, the pressure ring 2-2 is sleeved on the upper end of the chassis 1, the chassis 1 and the pressure ring There are 16 to 24 "U"-shaped grooves 7 processed up and down on the disc 2 a...

specific Embodiment approach 2

[0016] Specific implementation mode two: as figure 1 As shown, there are four locking shaft pins 3 and wedges 4 in this embodiment. In such a design, the chassis 1 and the pressure plate 2 are locked by four locking shaft pins 3 and wedges 4, so that the force on the split ring is uniform, and the quenching deformation of the split ring can be controlled. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0017] Specific implementation mode three: as image 3 with Figure 5 As shown, the number of "U"-shaped grooves 7 in this embodiment is 18-22. Such a design can increase the contact area between the open ring part and the quenching medium, and has a good cooling effect. While pressing the open ring part, it can uniformly harden all sides of the part and ensure the opening size of the open ring part. Other compositions and connections are the same as those in Embodiment 1 or 2.

[0018] Specific implementation mode four: as image 3 with Figure 5 As shown, the number of "U"-shaped grooves 7 in this embodiment is 20. Such a design can increase the contact area between the open ring part and the quenching medium, and has a good cooling effect. While pressing the open ring part, it can uniformly harden all sides of the part and ensure the opening size of the open ring part. Other components and connections are the same as those in the third embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com