A kind of preparation method of double perovskite magnetoresistance film

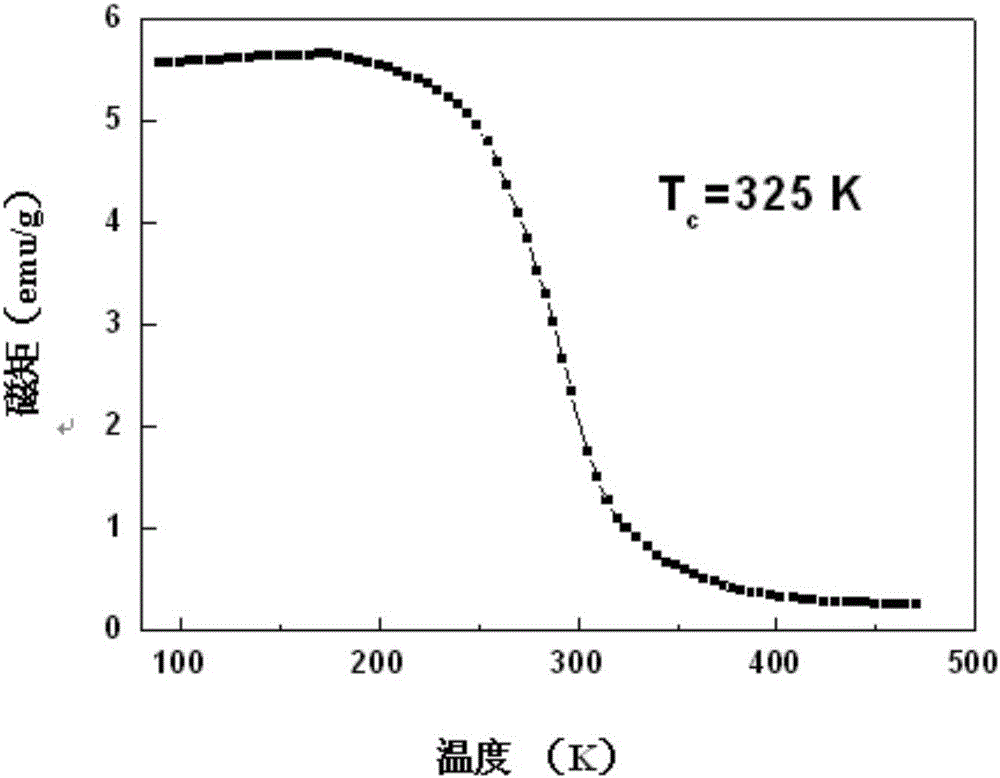

A double perovskite and magnetoresistance technology, which is applied in the fields of magnetic field controlled resistors, electromagnetic device manufacturing/processing, electrolytic coating, etc., can solve the difficulty of preparing high-quality thin films that are not suitable for large-scale industrial production, pulsed laser Expensive equipment and other issues, to achieve the effect of easy control of growth conditions, simple method, and high Curie temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

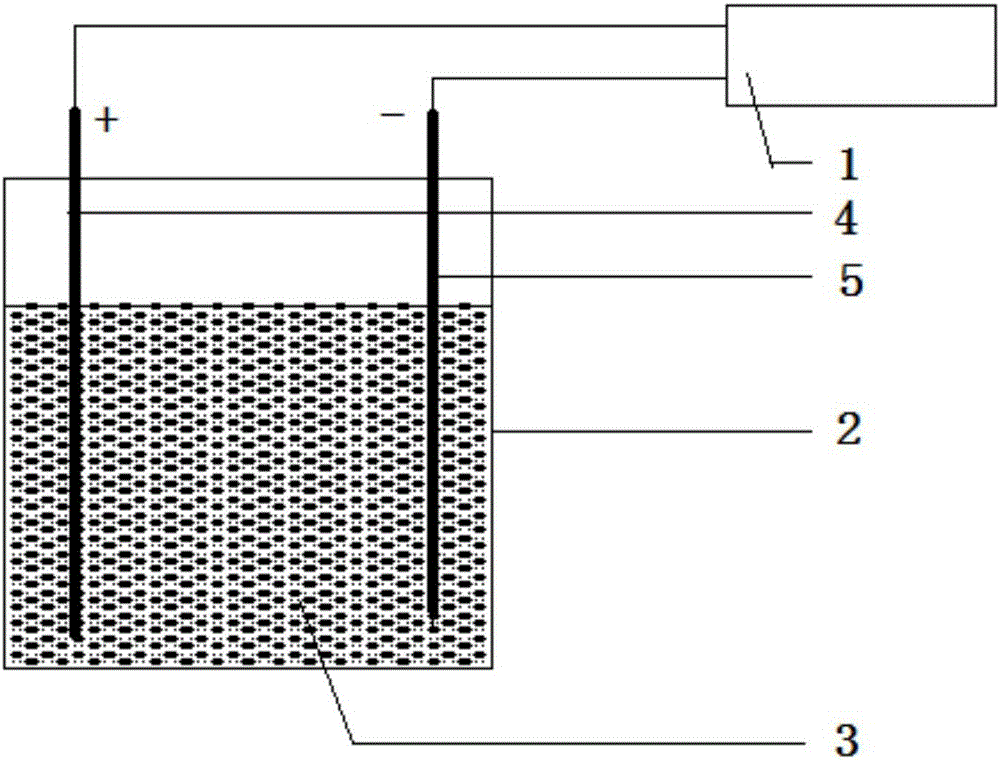

Method used

Image

Examples

Embodiment 1

[0041] Sr described in this example 2 FeMoO 6 The parent material was prepared as follows:

[0042] a. SrCO 3 , Fe 2 o 3 、MoO 3 The powder is pretreated in a muffle furnace at 300°C for 3 hours;

[0043] b. The pretreated SrCO 3 , Fe 2 o 3 and MoO 3 Mix evenly according to the mass ratio of 0.3413:0.0923:0.1664 and grind to a particle size of ≤70 μm, and place it in a muffle furnace for calcination at 900°C for 10 hours;

[0044] c. Grind the material obtained in step b to a particle size ≤ 40 μm, press into tablets, and use 5% volume fraction of H at 1280° C. 2 Sintering in a mixed flow atmosphere with 95% Ar by volume for 3 hours, and detecting the quality of the sample with a polycrystalline X-ray powder diffractometer;

[0045] When the sample is a single phase, the Sr 2 FeMoO 6 ;

[0046] When the sample contains an impurity phase, repeat the grinding, pressing, sintering, and detection steps in step c until the sample is a single phase, that is, Sr 2 FeMoO...

Embodiment 2

[0066] The Ba described in this example 2 FeMoO 6 The parent material was prepared as follows:

[0067] a. BaCO 3 , Fe 2 o 3 、MoO 3 The powder was pretreated in a muffle furnace at 250°C for 4 hours;

[0068] b. The pretreated BaCO 3 , Fe 2 o 3 and MoO 3 Mix evenly according to the mass ratio of 1.5954:0.3227:0.5819 and grind to a particle size of ≤60 μm, and place it in a muffle furnace for calcination at 900°C for 12 hours;

[0069] c. Grind the material obtained in step b to a particle size ≤ 40 μm, press into tablets, and use 5% volume fraction of H at 1230° C. 2 Sintering in a mixed flow atmosphere with 95% Ar by volume for 3 hours, and detecting the quality of the sample with a polycrystalline X-ray powder diffractometer;

[0070] When the sample is a single phase, Ba 2 FeMoO 6 ;

[0071] When the sample contains an impurity, repeat the steps of grinding, pressing, sintering, and detection in step c until the sample is a single phase, that is, Ba 2 FeMoO ...

Embodiment 3

[0075] Ca described in this example 2 FeMoO 6 The parent material was prepared as follows:

[0076] a. CaCO 3 , Fe 2 o 3 、MoO 3 The powder is pretreated in a muffle furnace at 350°C for 2 hours;

[0077] b. The pretreated CaCO 3 , Fe 2 o 3 and MoO 3 According to the mass ratio of 1.1803:0.4708:0.8489, mix evenly and grind to a particle size of ≤60 μm, and place it in a muffle furnace for calcination at 1000°C for 8 hours;

[0078] c. Grind the material obtained in step b to a particle size ≤ 40 μm, press into tablets, and use 5% volume fraction of H at 1250° C. 2 Sintering in a mixed flow atmosphere with 95% Ar by volume for 3 hours, and detecting the quality of the sample with a polycrystalline X-ray powder diffractometer;

[0079] When the sample is a single phase, the Ca 2 FeMoO 6 ;

[0080] When the sample contains an impurity phase, repeat the grinding, pressing, sintering, and detection steps in step c until the sample detection result is a single phase, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com