Method for preparing nano metal sulfides

A nano-metal and sulfide technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of product impurity and high temperature, and achieve easy-to-control particle size, uniform distribution, and easy construction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Configure the medium according to the following components: sodium acetate 1500mg; CaCl 2 .2H 2 O 80mg; MgSO 4 .7H 2 O 150mg; EDTA 20mg; Yeast extract 1200mg; K 2 HPO 4 1000mg; (NH 4 ) 2 SO 4 1500mg; KH 2 PO 4 800mg; FeSO 4 .7H 2 O 10mg trace element solution 3ml: deionized water 1500ml. The pH of the medium was 7.

[0040] Wherein the trace element solution is composed of: H 3 BO 3 240 mg; Na 2 MoO 4 .2H 2 O 70mg; CuSO 4 7 mg; MnSO 4 .4H 2 O 200mg; ZnSO 4 .7H 2 O 24mg; deionized water 1650ml.

[0041] Inoculate 1 / 20 portion of Rhodobacter sphaeroides into the sterilized culture medium, and cultivate it for 20 days under light of 2500 lux, room temperature, and anaerobic conditions, as the inoculum;

[0042] The cultured Rhodobacter sphaericus was centrifuged at 6000rpm for 10min, the precipitate was washed with normal saline and centrifuged twice. Then mix the obtained 10% concentrated bacteria with 10% polyvinyl alcohol solution cooled to 3...

Embodiment 2

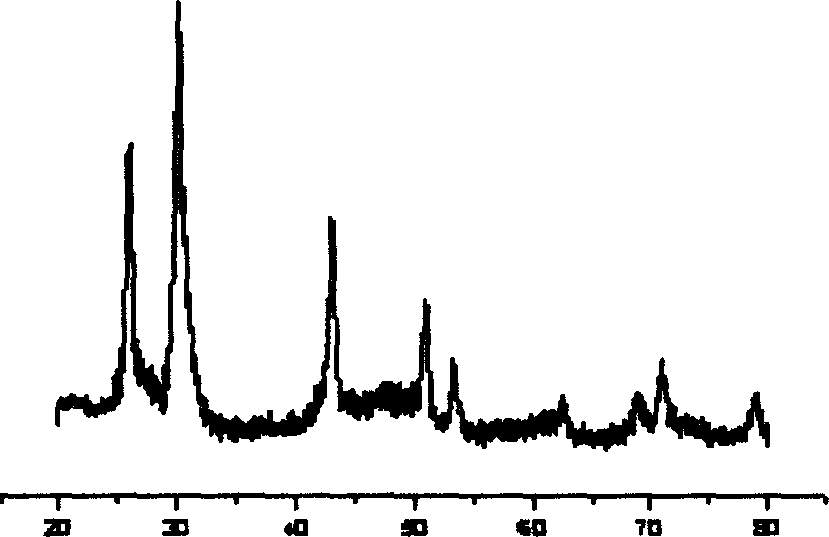

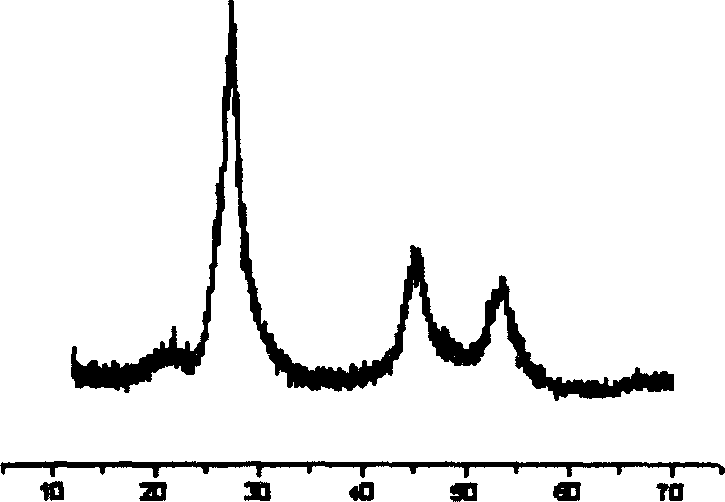

[0046] Using Rhodopseudomonas palustris, adding 0.20mol / L of Pb(AC) a 10ml, transformation culture time 36h, other conditions and steps are identical with embodiment 1, the product nano-lead sulfide average particle diameter that obtains is 25nm, productive rate 90%, black powder, x-ray analysis result is cubic structure, and purity is high.

Embodiment 3

[0048] Rhodopseudomonas palustris (Rhodopseudomonas palustris) and spherical red bacillus (Rhodobactersphaeroides) were mixed and immobilized by 1:1, and the transformation culture time was 40h. Other conditions and steps were the same as in Example 1. 23nm, 89% yield, black powder, X-ray analysis shows cubic structure, high purity.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com