Technology for processing textile wastes into regenerated cotton

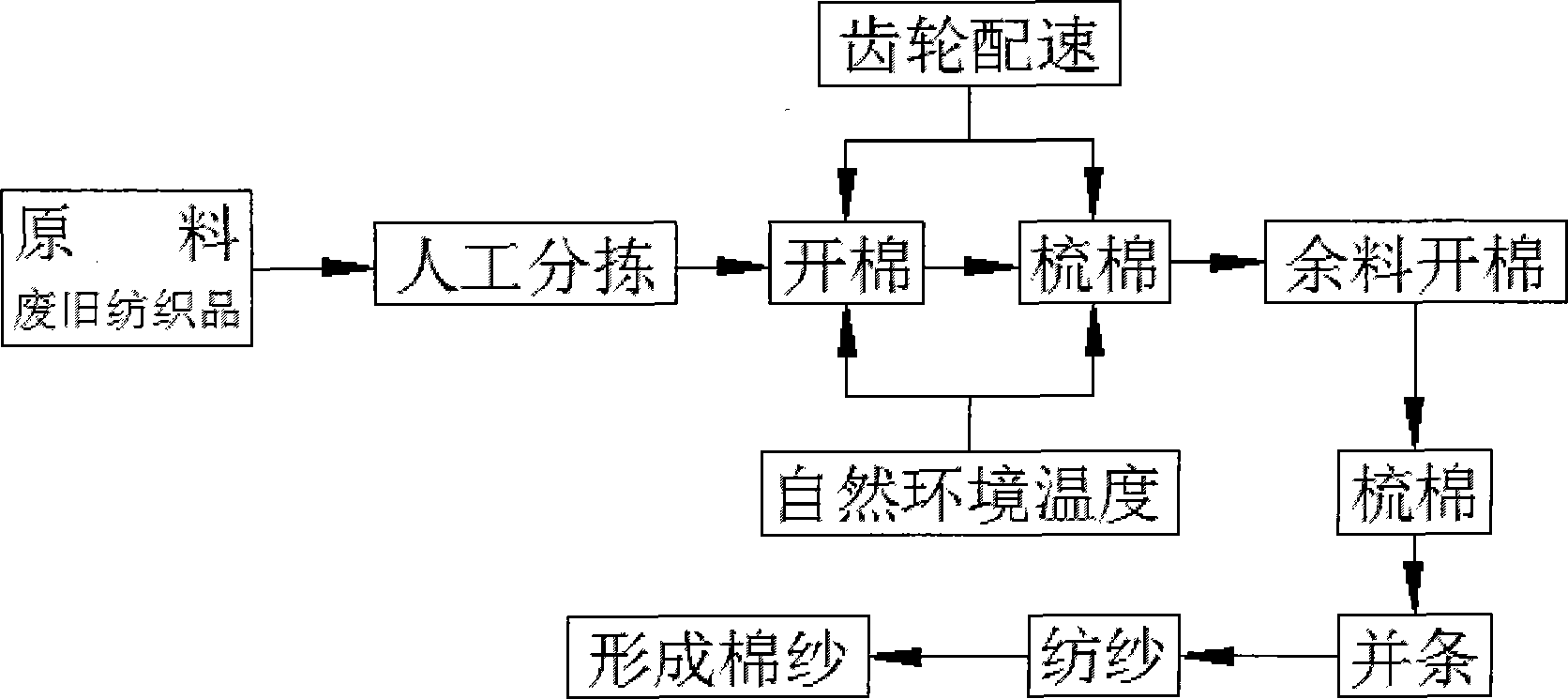

A processing technology and waste technology, which is applied in the field of textile waste regenerated cotton processing technology, can solve the problems of unsteady fiber length and strength quality, unstable fiber quality, and affecting production efficiency, etc., and achieve low-speed and high-efficiency yarn formation process, improve product quality, and save resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

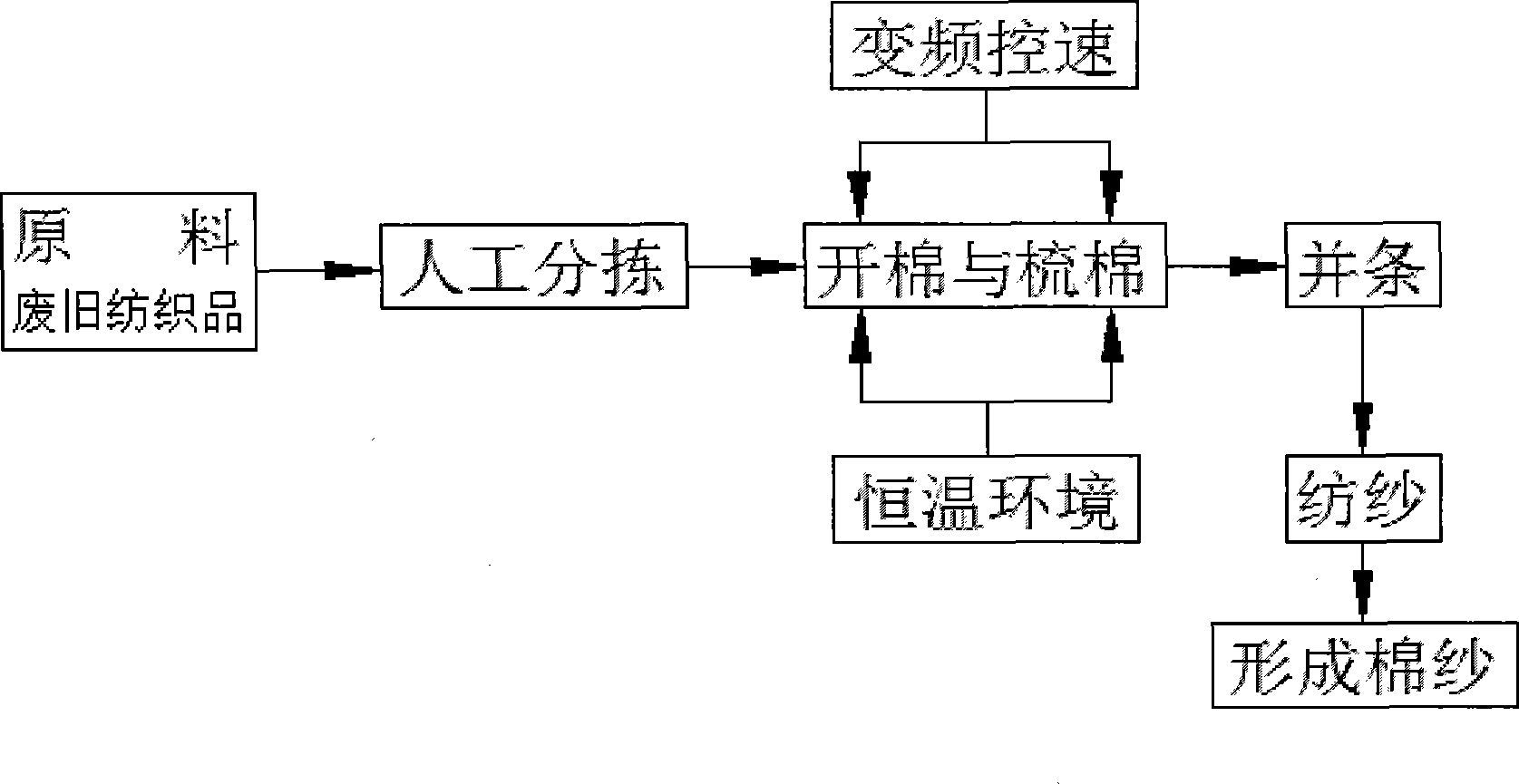

[0015] The technical solution of the present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the scope of protection is not limited to the description.

[0016] Such as figure 2 As shown, a process for processing recycled cotton from textile waste according to the present invention includes the steps of manual sorting, cotton opening and carding, drawing, and spinning.

[0017] (1) Manual sorting: Preliminary classification of waste textile raw materials is carried out manually, and waste and impurities that do not meet the reprocessing requirements are removed;

[0018] (2) Cotton opening and carding: The raw materials are sent to the cotton opening equipment for opening, and after opening, they are sent to the carding equipment to complete carding. The proportion of humidification for different raw materials is 6% to 8% of the weight of the raw materials, and the relative humidity is guaranteed to be 63% to 67%, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com