A kind of dyeing process of cashmere cheese

A cheese and process technology, applied in the field of cashmere cheese dyeing technology, can solve problems such as loss of production enterprises, and achieve the effects of less cashmere damage, high dyeing rate and high dyeing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The dyeing process of the cashmere cheese yarn is as follows: take the cashmere cheese yarn for quality inspection, after passing the test, put it in a cage, put it into a cylinder, first carry out pretreatment according to the pretreatment process, and then carry out dyeing treatment according to the dyeing process, using a high-frequency dehydrator to 1600r / min rotation speed for dehydration, use radio frequency dryer to dry at a cloth speed of 15m / h, carry out quality inspection, tighten the cylinder, and pack it.

[0050] The pretreatment process is as follows: in the pretreatment solution with a bath ratio of 1:10 at room temperature, firstly add 2% NaHCO3 and 2% oxygen bleach activator tetraacetylethylenediamine (TAED) in the treatment solution, and then heat up to 2%. Treat at 40°C for 60min, add 1% deoxygenase, treat at 40°C for 10min, wash with water at 40°C for 8min, and drain.

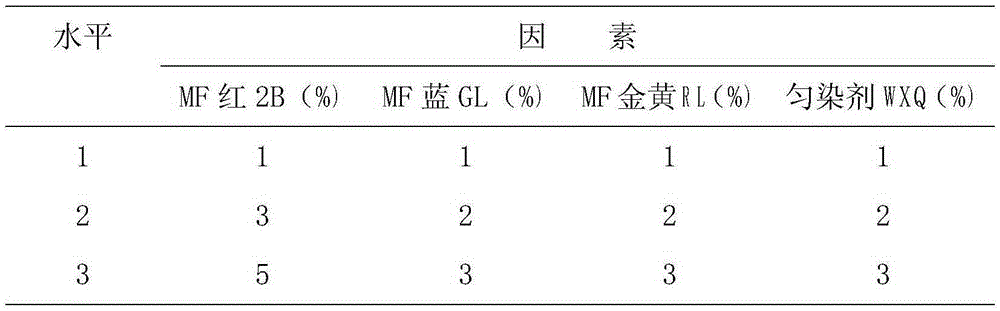

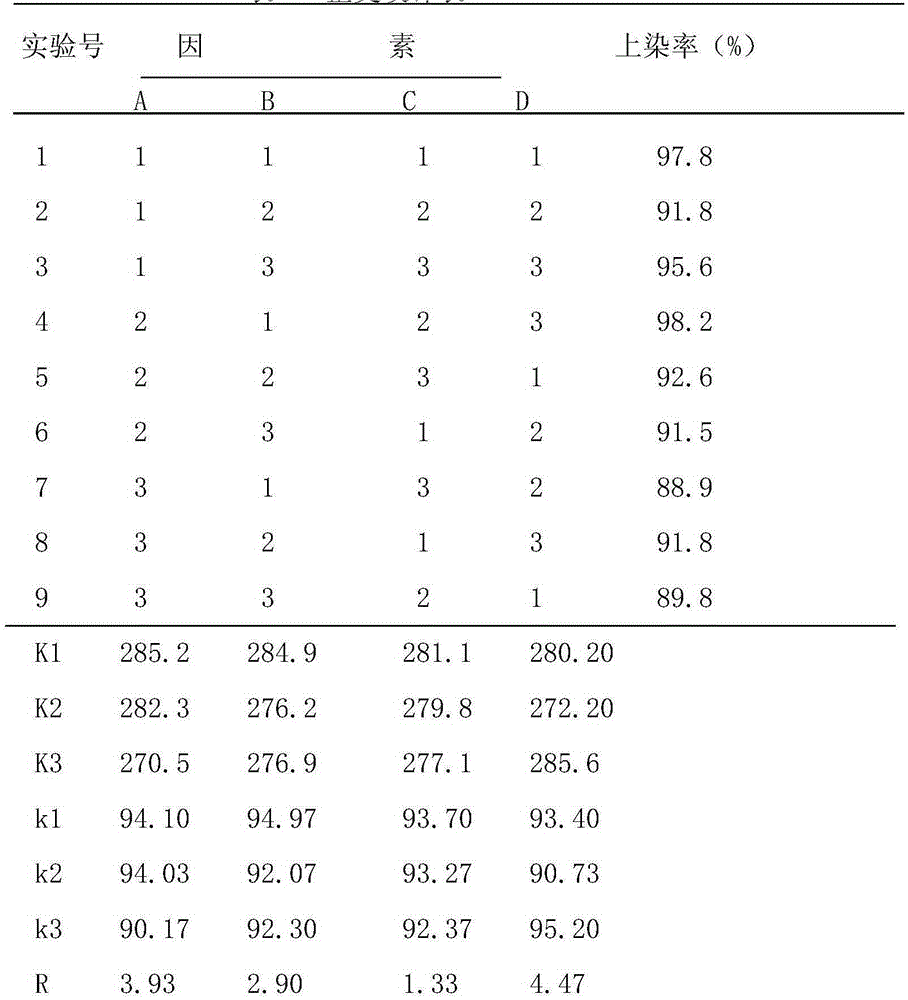

[0051] The dyeing process is: 1% MF red 2BL, 1% MF blue GL, 1% MF golden yellow R...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com