Method for rut maintaining and paving of municipal road

A technology for municipal roads and rutting is applied in the field of municipal road rutting maintenance and paving to achieve the effects of dispersing compressive stress, suppressing reflection cracks, and preventing interlayer slippage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

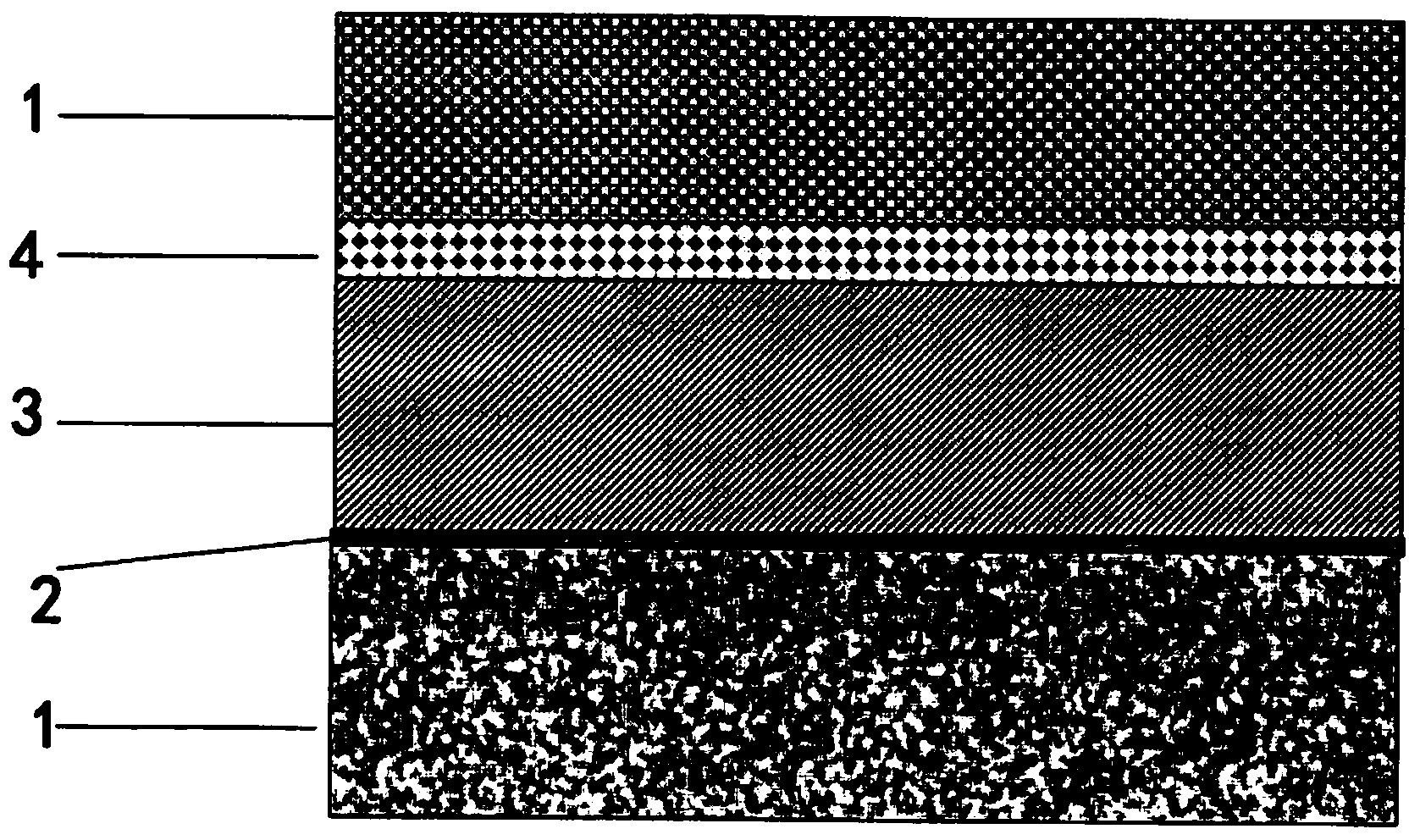

[0061] As shown in Figure 1, a kind of municipal road rut maintenance pavement method comprises the following steps:

[0062] 1) Asphalt surface layer milling: use a milling machine to mill the asphalt surface layer layer by layer until the original pavement base layer is exposed. If there are cracks in the base layer, the joints need to be filled, and the milling material is sent to the factory for cold recycling and mixing Station for screening, divided into three grades of material: 0-5mm, 5-15mm, 15-30mm;

[0063] 2) Spreading of modified emulsified asphalt sticky layer: After the milling of the asphalt surface layer of the original pavement is completed, the surface of the base layer is cleaned, dried and then spread SBS modified emulsified asphalt. The spread amount of SBS modified emulsified asphalt is 0.5kg / m 2 ,SBS modified emulsified asphalt is from Jiangsu Keinge Special Asphalt Co., Ltd.;

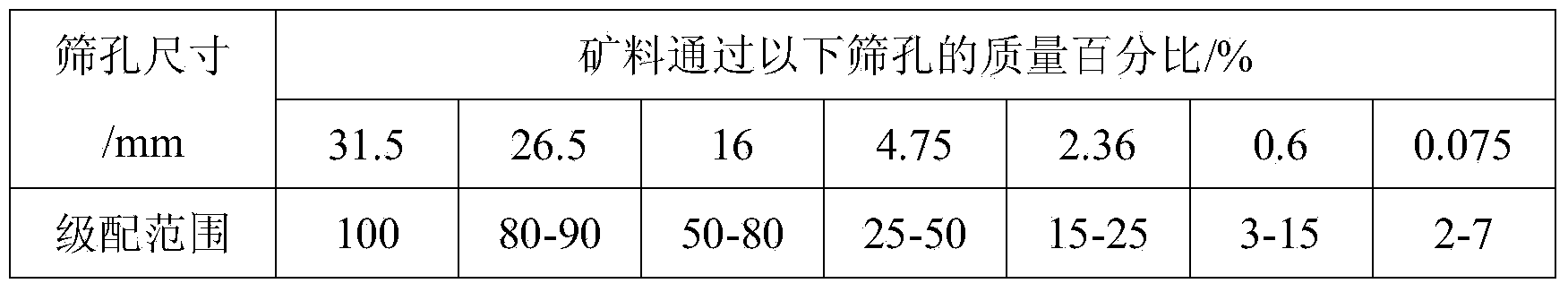

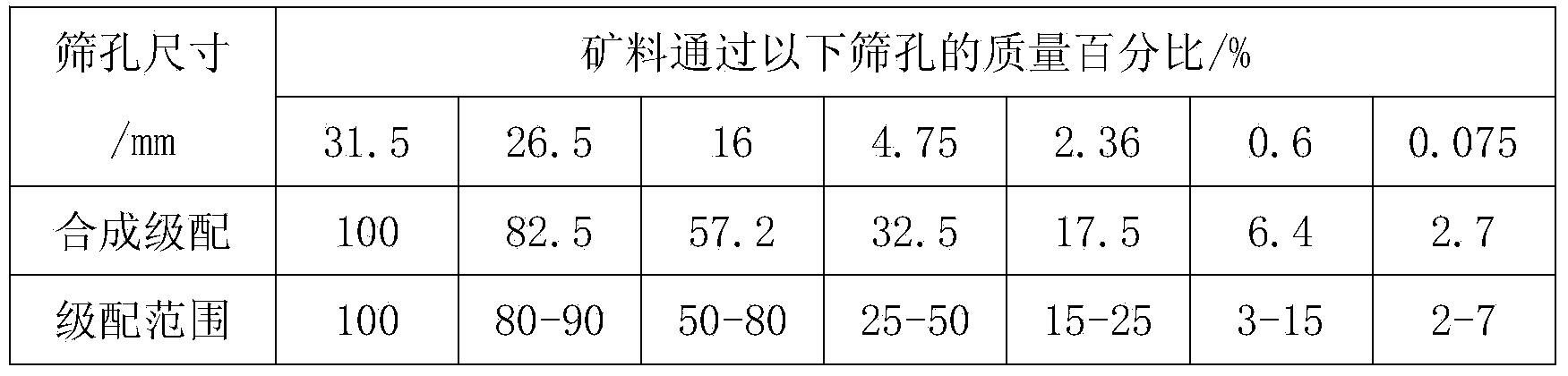

[0064] 3) Paving of the lower layer of emulsified asphalt cold recycled m...

Embodiment 2

[0120] A municipal road rut maintenance pavement method, comprising the following steps:

[0121] 1) Asphalt surface layer milling: use a milling machine to mill the asphalt surface layer layer by layer until the original pavement base layer is exposed. If there are cracks in the base layer, the joints need to be filled, and the milling material is sent to the factory for cold recycling and mixing The station screens and divides into three grades of materials (0-5mm, 5-15mm, 15-30mm) for processing;

[0122] 2) Spreading of modified emulsified asphalt sticky layer: After the milling of the asphalt surface layer of the original pavement is completed, the surface of the base layer is cleaned, dried and then spread SBS modified emulsified asphalt. The spread amount of SBS modified emulsified asphalt is 0.6kg / m 2 , SBS modified emulsified asphalt is from Jiangsu Keinge Special Asphalt Co., Ltd.;

[0123] 3) Paving of the lower layer of emulsified asphalt cold recycled mixture; ...

Embodiment 3

[0179] A municipal road rut maintenance pavement method, comprising the following steps:

[0180] 1) Asphalt surface layer milling: use a milling machine to mill the asphalt surface layer layer by layer until the original pavement base layer is exposed. If there are cracks in the base layer, the joints need to be filled, and the milling material is sent to the factory for cold recycling and mixing The station screens and divides into three grades of materials (0-5mm, 5-15mm, 15-30mm) for processing;

[0181] 2) Spreading of modified emulsified asphalt sticky layer: After the milling of the asphalt surface layer of the original pavement is completed, the surface of the base layer is cleaned, dried and then spread SBS modified emulsified asphalt. The spread amount of SBS modified emulsified asphalt is 0.65kg / m 2 , SBS modified emulsified asphalt is from Jiangsu Keinge Special Asphalt Co., Ltd.;

[0182] 3) Paving of the lower layer of emulsified asphalt cold recycled mixture; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Splitting strength | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com