A plastic cable splint

A technology of plastic cables and splints, which is applied in the installation of cables, the arrangement of cables between relatively moving parts, and electrical components, etc. It can solve the problems of cable outer surface loss and other problems, and achieves wide application range, light material, and high wear resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

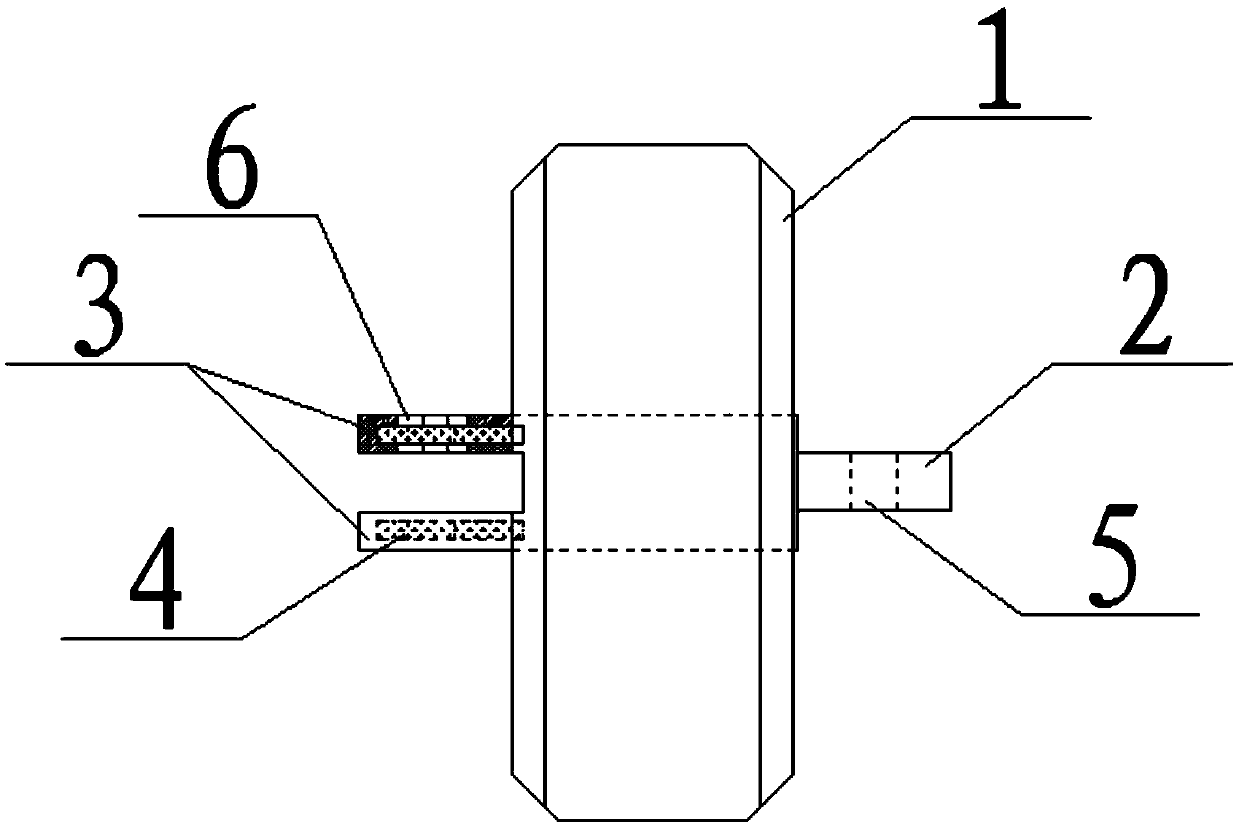

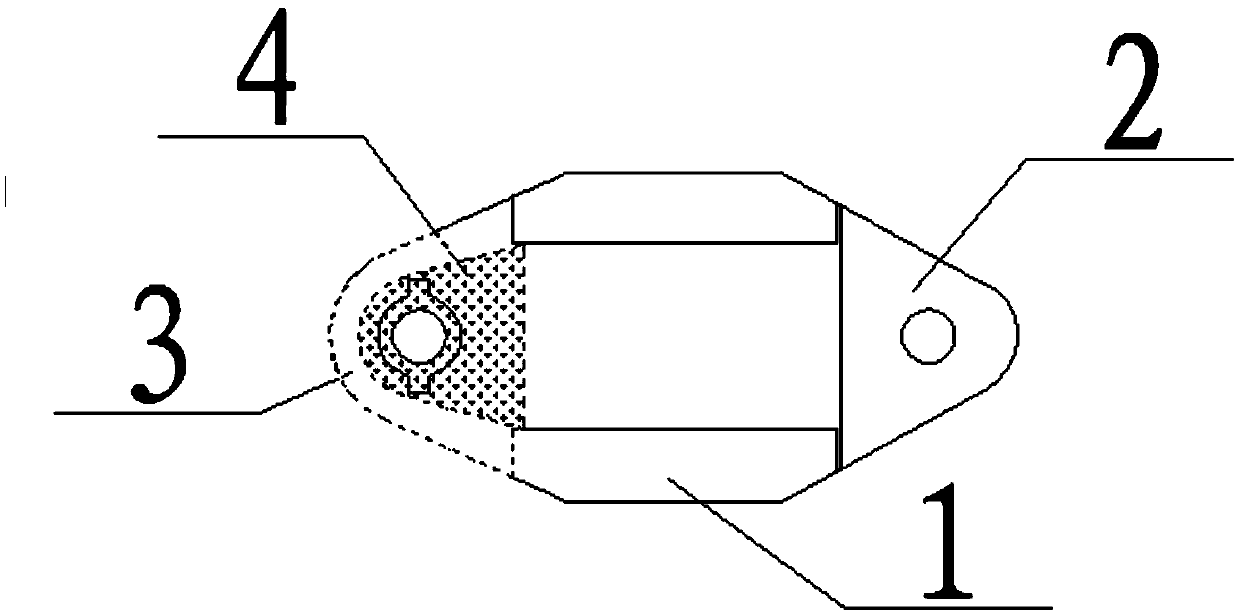

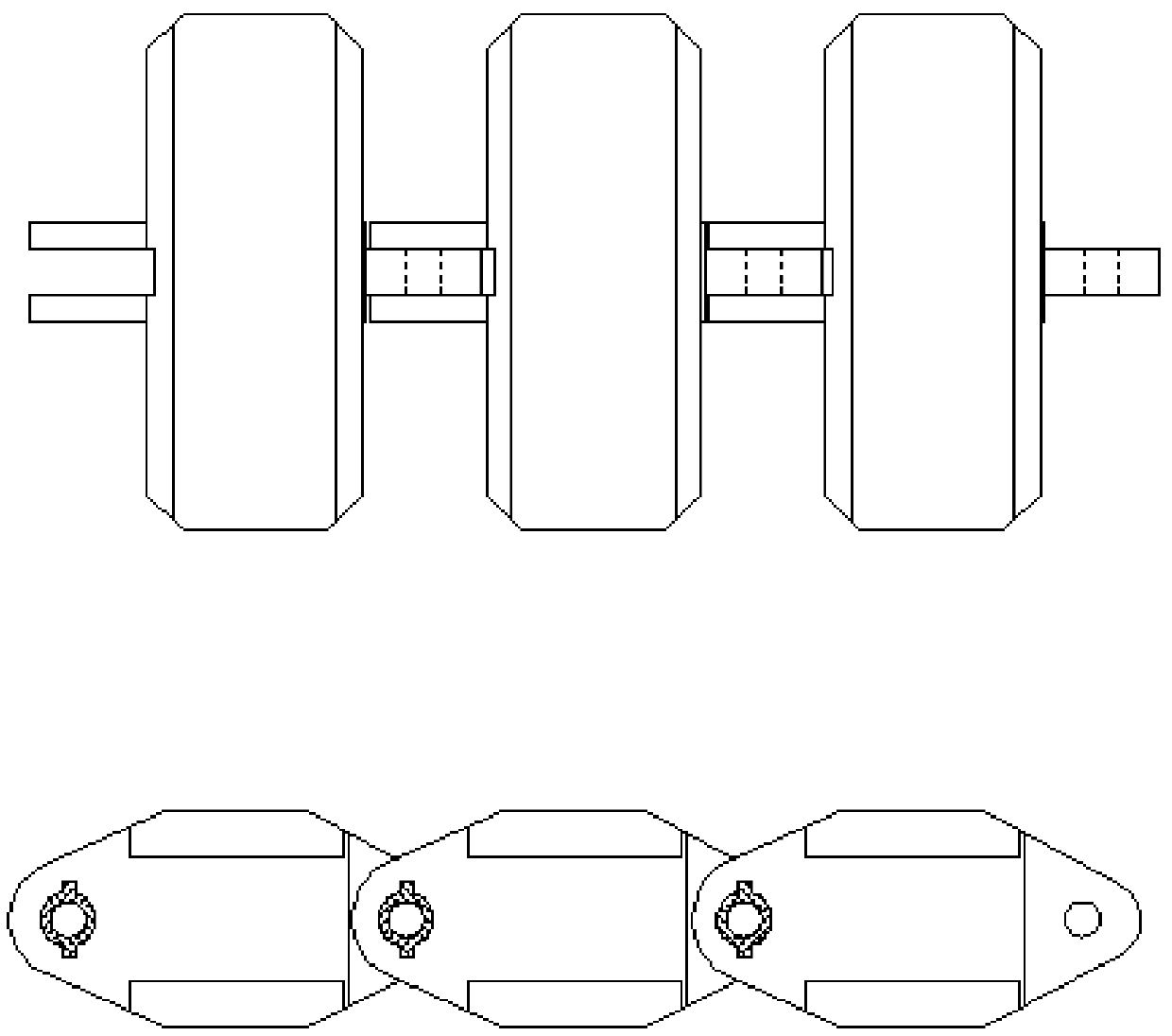

[0013] Referring to the accompanying drawings, a plastic cable splint includes a splint body 1 and connection structures 2 and 3 arranged on the body. The splint body is made of plastic material, the connection structure is made of plastic material as a whole, and a metal plate 4 is arranged inside. The plastic material formulation contains high-strength PA 6 70-80%, melamine 3-6%, antimony trioxide 5-6%, CPE metal rare earth 1-3%, KH550 coupling agent 2-3%, auxiliary agent 2-5%; the splint body is H shape; the connection structure is a U-shaped structure 3 arranged on one side of the splint body and a plate-shaped structure 2 arranged on the other side of the splint body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com