Heavy oil well test spiral synergy heating pipe

A technology for heating pipes and oil wells, applied in pipeline heating/cooling, pipes/pipe joints/fittings, mechanical equipment, etc. It can solve problems such as no heating function, no flow, increased viscosity, etc., to prolong heating time and reduce transportation Effect of resistance and viscosity reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

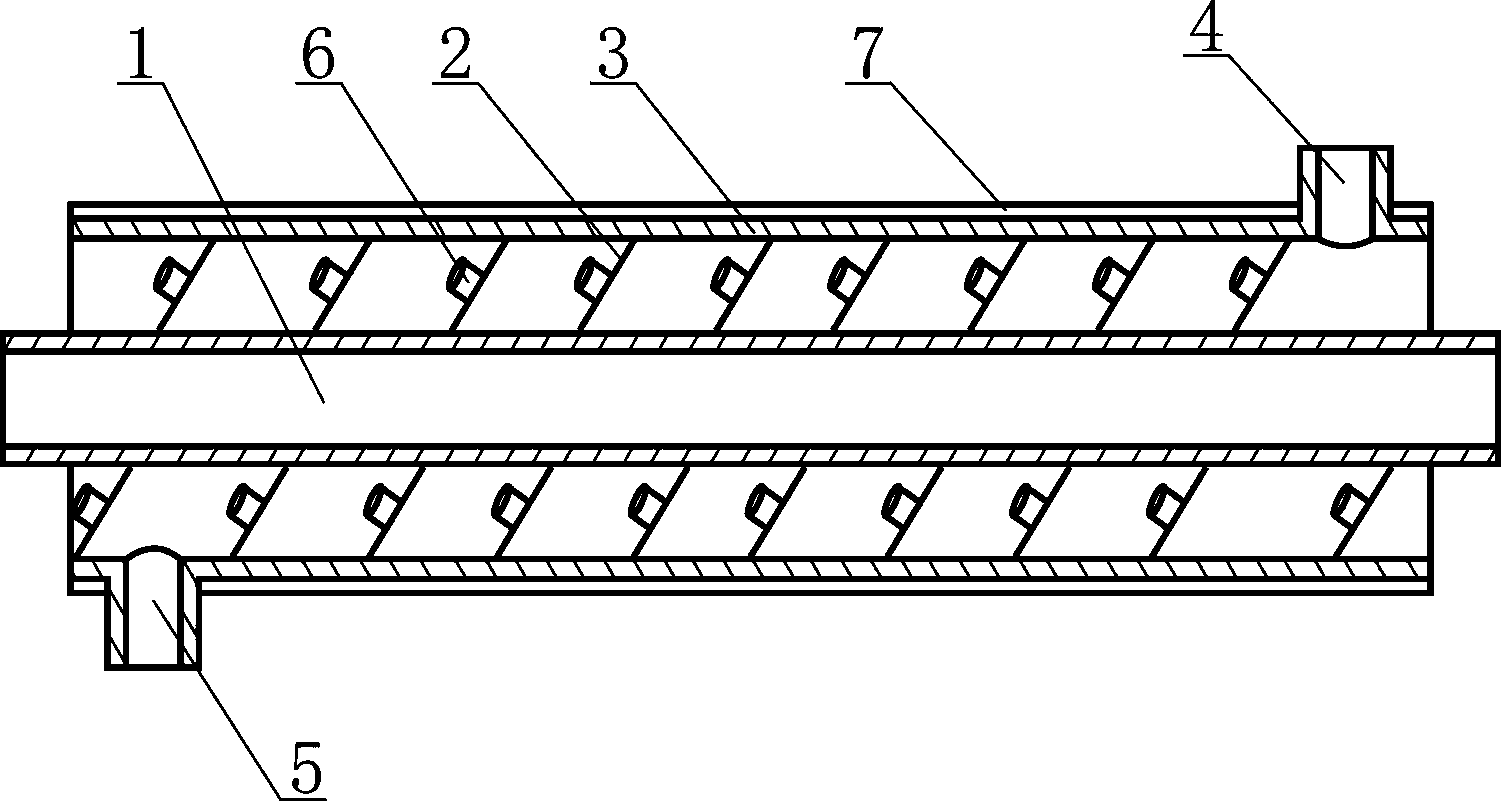

[0013] Such as figure 1 As shown, a spiral synergistic heating tube for heavy oil well testing is mainly composed of a heavy oil delivery pipe 1, a spiral partition 2 and a casing 3. The spiral partition 2 is wound around the periphery of the heavy oil delivery pipe 1 and along the The heavy oil delivery pipe 1 extends in the axial direction, and the casing 3 is sleeved on the periphery of the spiral partition 2 , and the surface of the casing 3 is provided with a heat insulating layer 7 . A hot water inlet 4 is provided on the pipe wall of the casing 3 near the end of the casing, a hot water outlet 5 is provided on the pipe wall of the casing 3 and near the other end of the casing, the heavy oil delivery pipe 1, the casing 3 A spiral water flow channel is surrounded by the spiral partition plate 2. A plurality of turbulence stimulating protrusions 6 are uniformly distributed on the spiral partition 2 .

[0014] Working principle: The hot water inlet 4 and the hot water out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com