Numerical control machining tool feeding and retracting track interference check method based on dynamic visualization

A technology of interference checking and processing trajectory, which is applied in the direction of program control, computer control, general control system, etc., can solve the problems affecting the production efficiency and economic benefits of enterprises, affecting the production cycle of parts processing, and heavy repetitive workload, so as to save work Quantity, reduce the probability of error, the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The following structural drawings and embodiments further illustrate the present invention.

[0038] Such as Figure 1-8 shown.

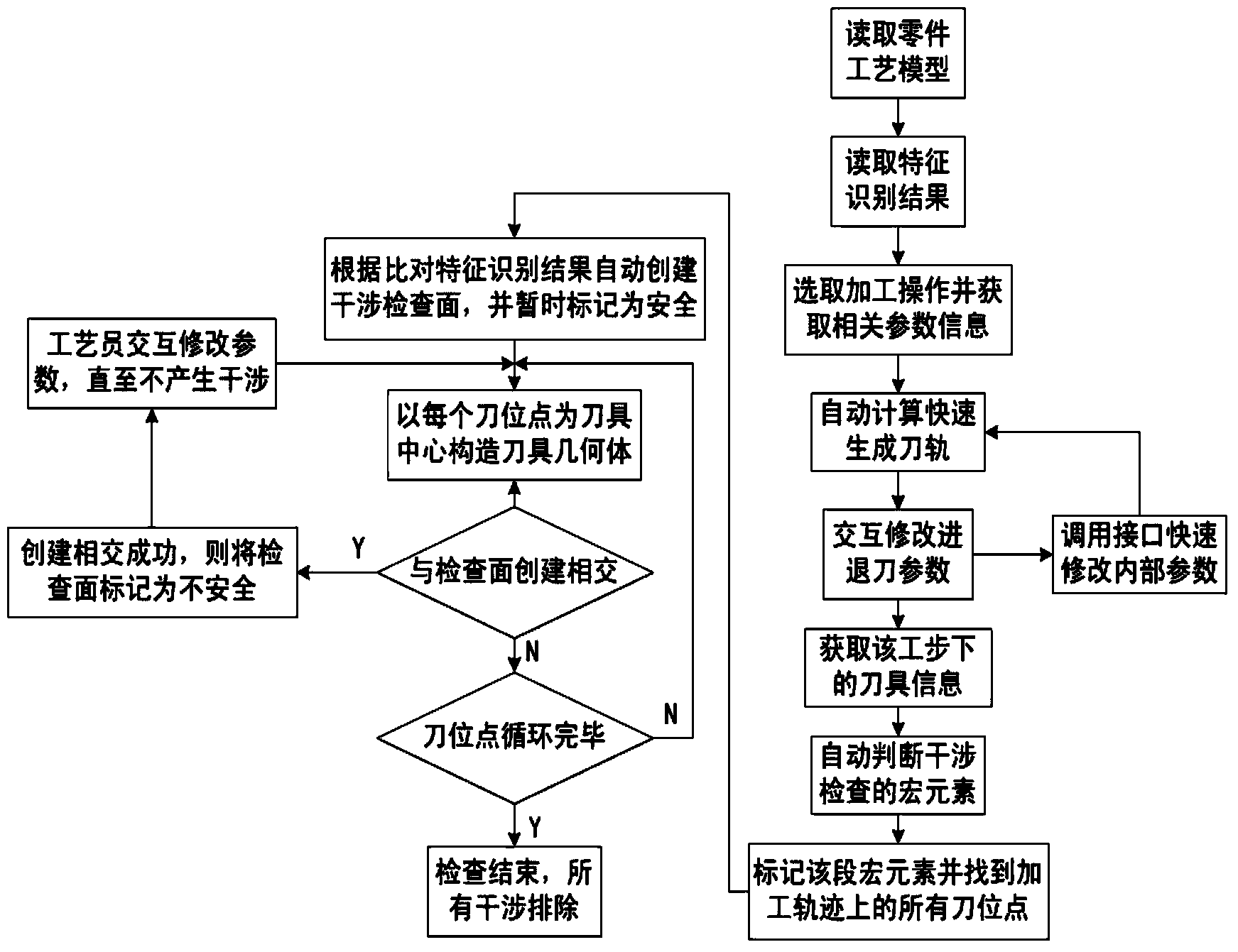

[0039] A dynamic visualization-based inspection method for NC machining advance and retreat tool path interference can be summarized as the following 11 steps:

[0040] Step 1: Read the part process model.

[0041] Step 2: Read the part feature recognition result list.

[0042] Step 3: Select the processing operation of the advance and retreat tool interference check and obtain the relevant parameter information.

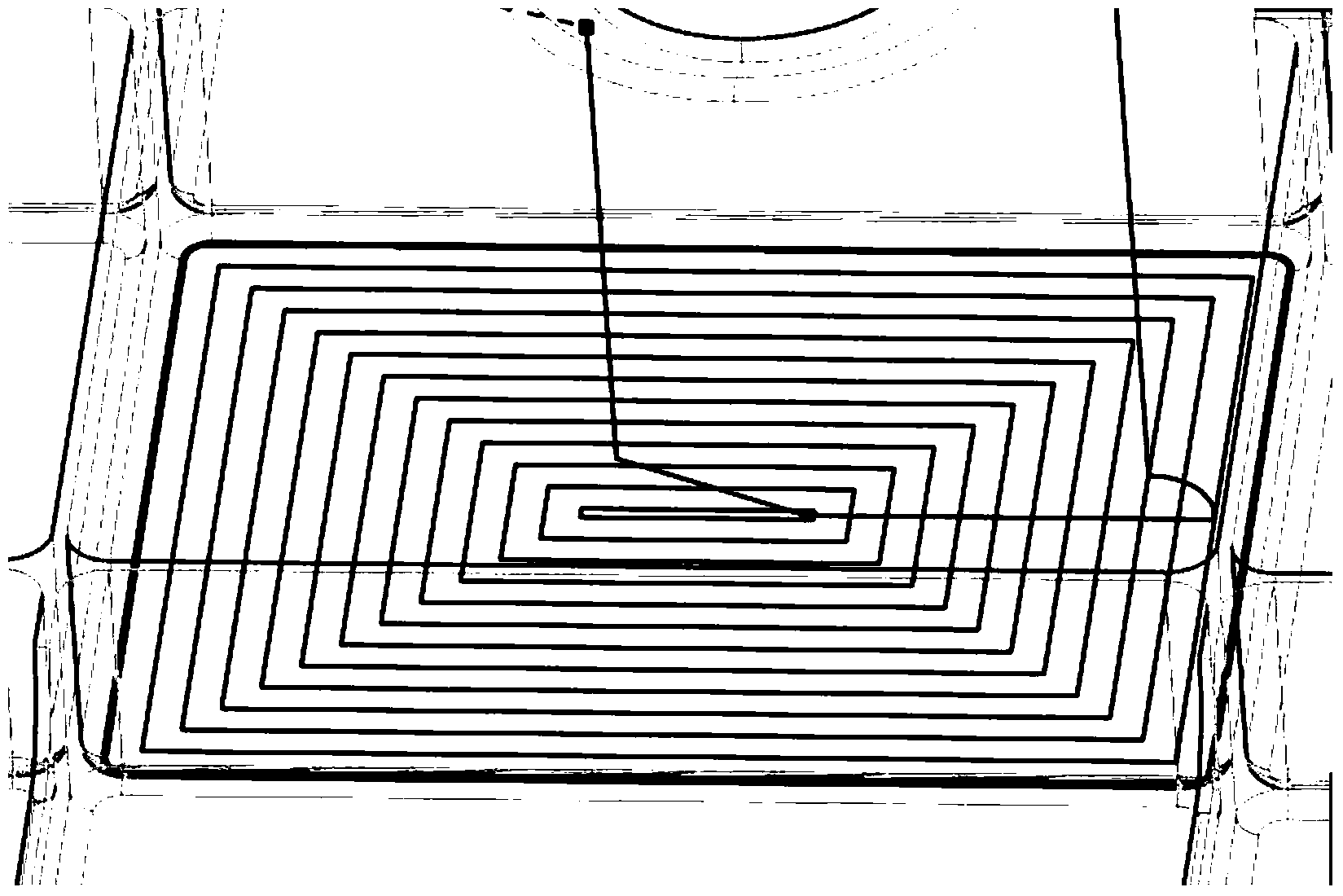

[0043] Step 4: Quickly generate the machining trajectory of the machining operation.

[0044] Step 5: Generate the modified tool path in real time according to the parameters modified interactively by engineers.

[0045] Step 6: Extract tool model information.

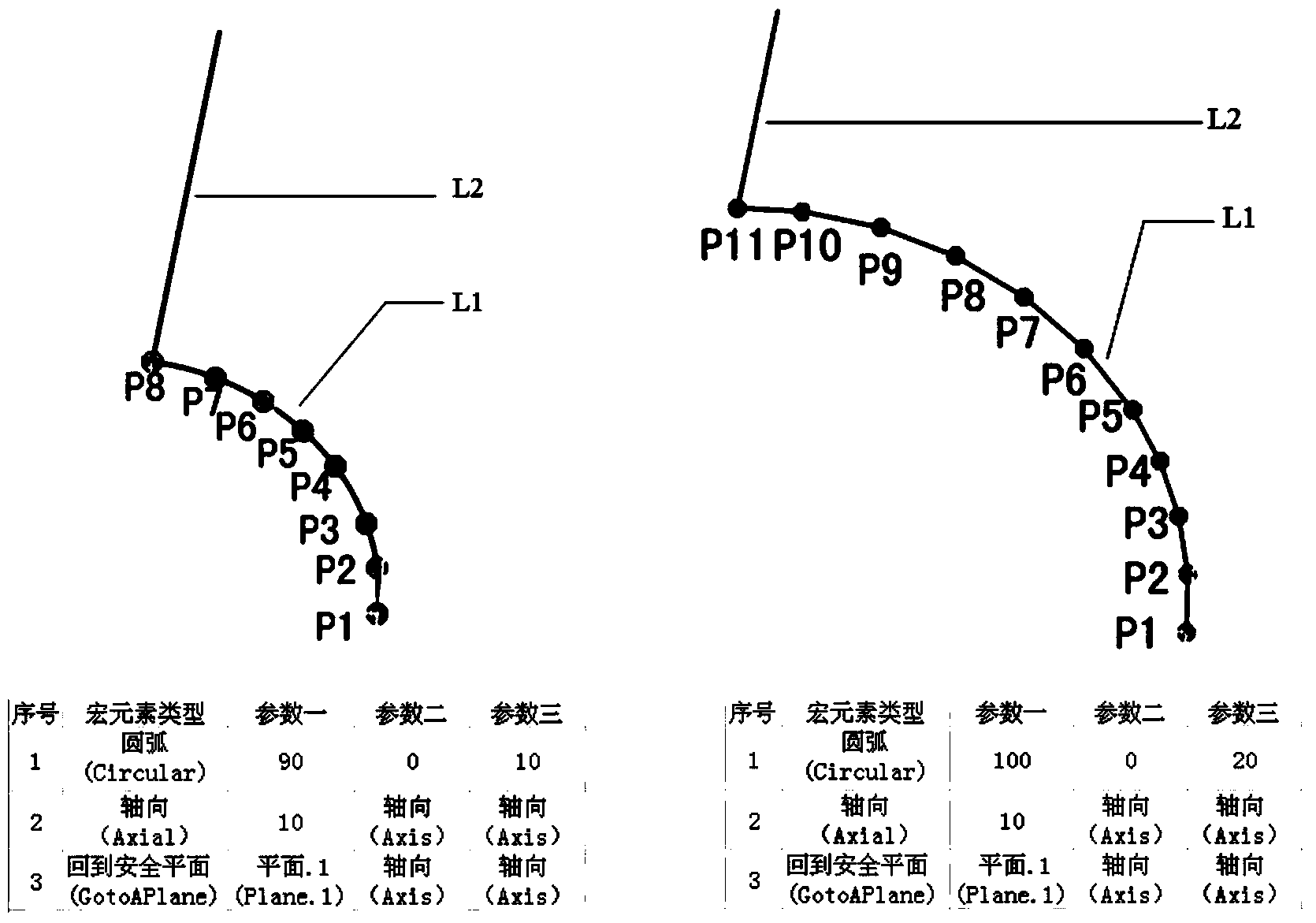

[0046] Step 7: Automatically judge the macro elements of the advance and retreat tools that need to be checked.

[0047] Step 8: Automatically obtain the tool positi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com