Single-sensor double-frequency output resonant circuit and design method thereof

A resonant circuit and inductor technology, applied in induction heating and other directions, can solve the problems of poor frequency selection performance of resonant circuit, complex resonant circuit structure, asynchronous dual-frequency output, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

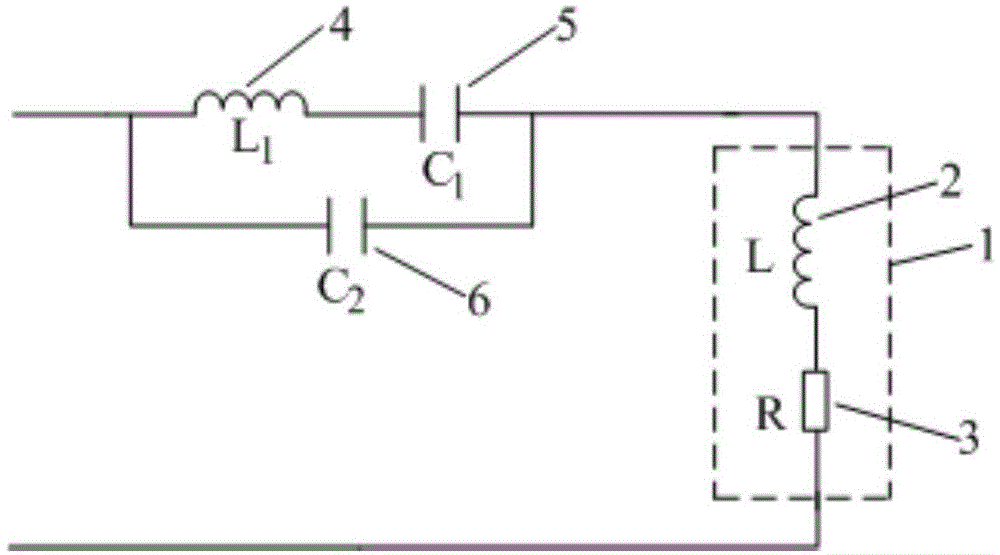

[0102] Embodiment 1, a single-inductor dual-frequency output resonant circuit, including a connected single-inductor 1 and an auxiliary resonant circuit, the single-inductor 1 is composed of an inductor equivalent inductance L2 and an inductor equivalent resistance R3 connected in series; The auxiliary resonant circuit consists of a resonant inductor L 1 4 and the resonant capacitor C 1 5 in series and then with the resonant capacitor C 2 6 are connected in parallel. Its design method is as follows:

[0103] Step 1, determine the resonant circuit topology:

[0104] Resonant inductance L 1 4 and the resonant capacitor C 1 5 in series and then with the resonant capacitor C 2 6 are connected in parallel to form an auxiliary resonant circuit, and the single inductor 1 is connected to the auxiliary resonant circuit to form a resonant circuit.

[0105] Step 2, seek the design parameters of the resonant circuit;

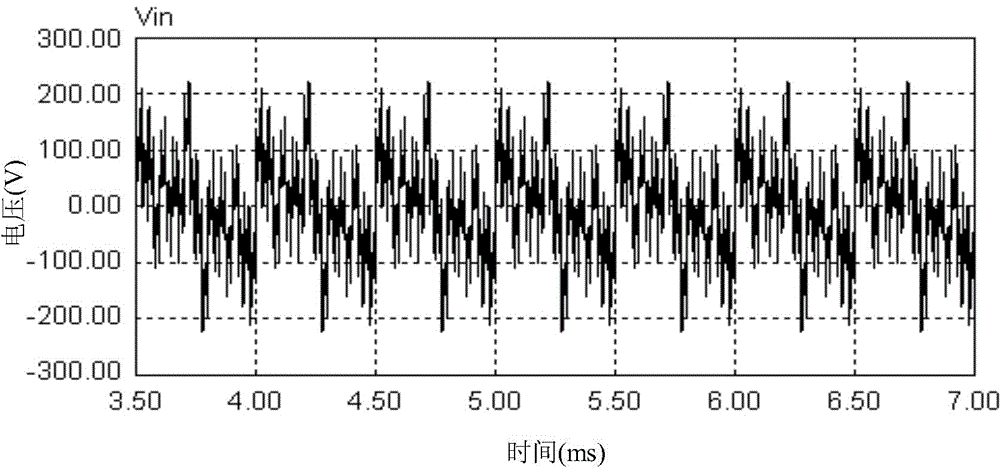

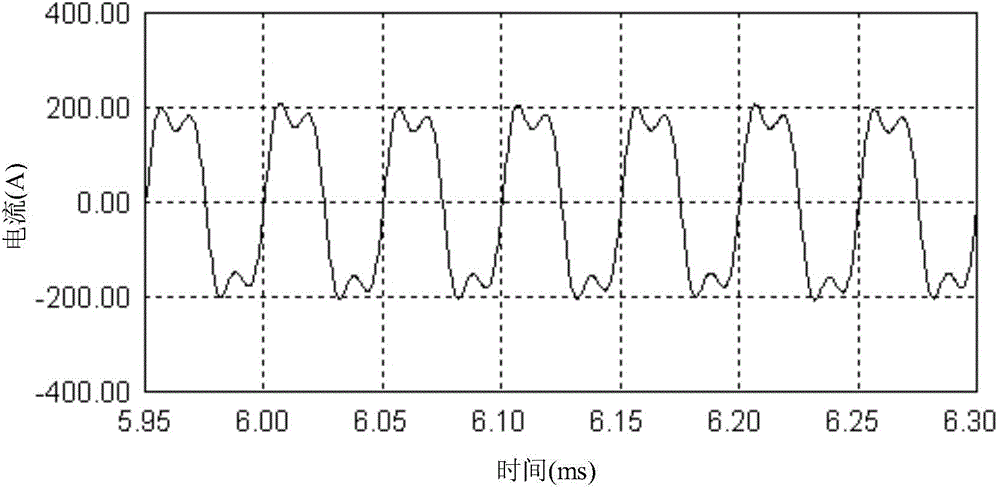

[0106] Select the frequency f of the two signals to be output ...

Embodiment 2

[0116] Embodiment 2, a single-inductor dual-frequency output resonant circuit, including a connected single-inductor and an auxiliary resonant circuit, the single-inductor is composed of an inductor equivalent inductance L and an inductor equivalent resistance R connected in series; the auxiliary resonant The circuit consists of a resonant inductor L 1 and resonant capacitor C 1 connected in series with the resonant capacitor C 2 formed in parallel. Its design method is as follows:

[0117] Step 1, determine the resonant circuit topology:

[0118] Resonant inductance L 1 and resonant capacitor C 1 connected in series with the resonant capacitor C 2 The auxiliary resonant circuit is formed by parallel connection, and the single inductor is connected with the auxiliary resonant circuit to form a resonant circuit.

[0119] Step 2, determining the design parameters of the resonant circuit;

[0120] First select the frequency f of the two signals to be output 1 , f 2 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com