Wiring board for having light emitting element mounted thereon

A technology for light-emitting elements and wiring substrates, which can be applied to electrical components, circuit devices, and electrical solid-state devices, etc., and can solve the problems of obstructing the optical path, low luminous efficiency, and obstructing the optical path of the light-emitting element.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

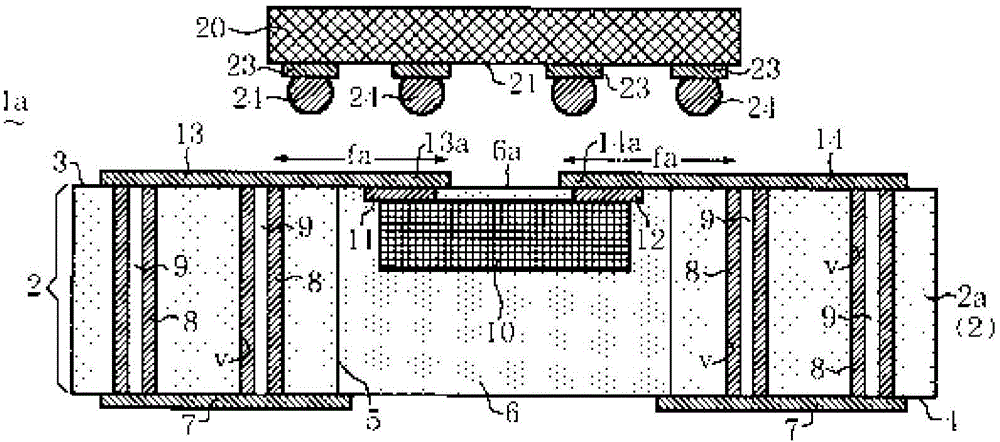

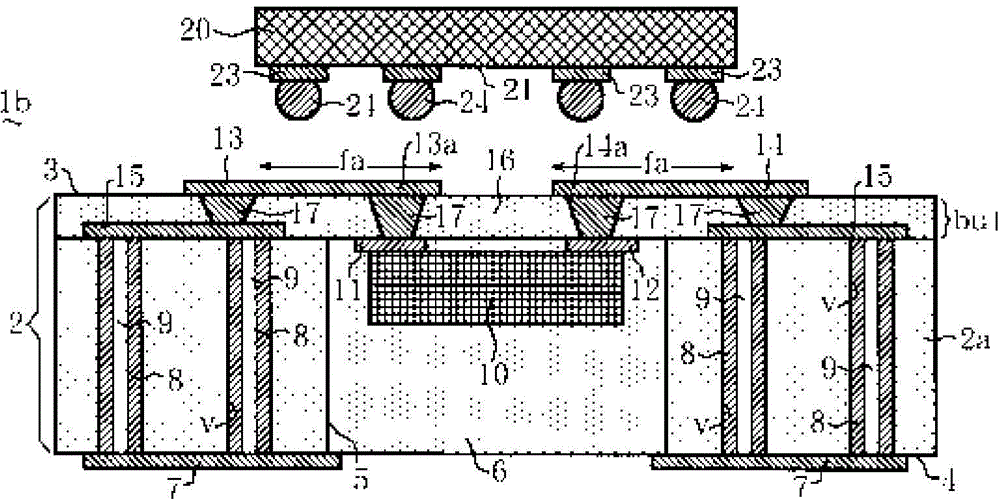

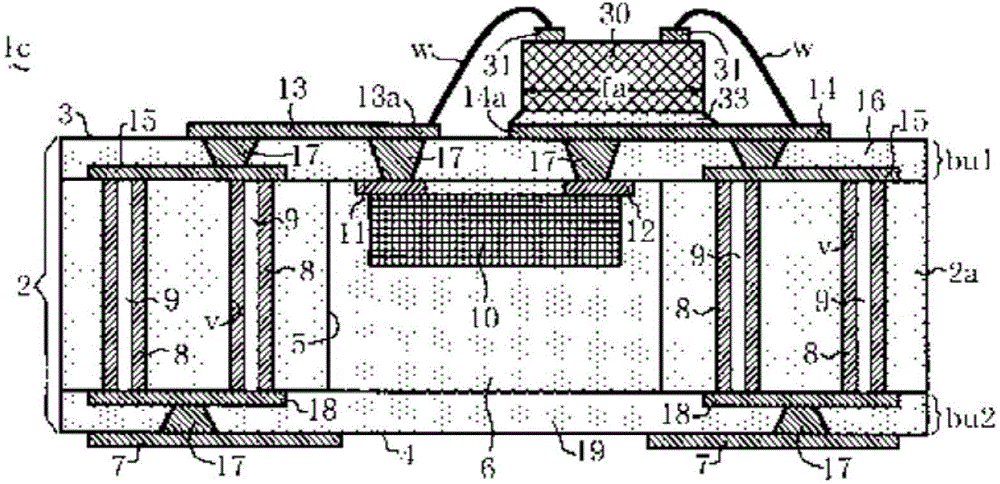

[0026] Embodiments for carrying out the present invention will be described below. figure 1 It is a vertical cross-sectional view showing a wiring board 1 a for mounting a light emitting element and a light emitting diode (light emitting element) 20 mounted on the wiring board 1 a for mounting a light emitting element according to an embodiment of the present invention. like figure 1 As shown, the wiring substrate 1a for mounting light-emitting elements includes: a substrate body 2 having a surface 3 and a back surface 4 and having a plate shape as a whole; a pair (multiple) of element terminals 13, 14 formed on the substrate body 2 A pair of external connection terminals 7, 7 formed on the back surface 4 of the substrate body 2; and a Zener diode (built-in component) 10 built in the substrate body 2. The substrate main body 2 is composed of a core substrate (insulating substrate) 2 a made of hard resin or ceramics and having a thickness of about 30 μm to 1000 μm. Hard resin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com