Whole-grain health tea and manufacturing method thereof

A production method and technology of whole grains, which are applied in the field of food processing, can solve the problems of rough taste, difficult to arouse people's appetite, and indigestibility of miscellaneous grains, and achieve the effect of delicate taste, easy absorption, and high utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

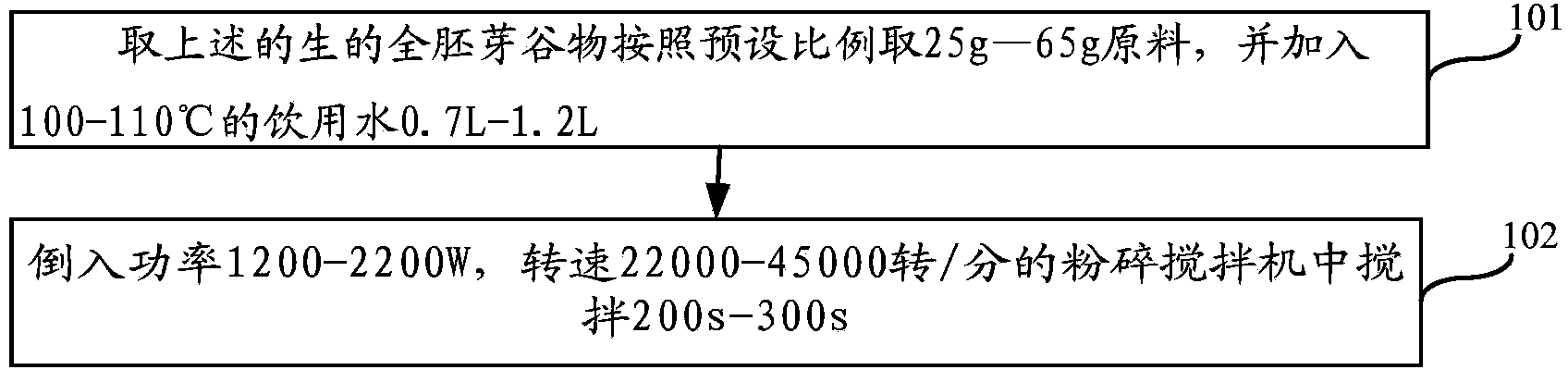

[0041] A kind of preparation method of whole grain healthy tea and its preparation method, such as figure 1 As shown, the following preparation steps are included:

[0042] 1) Take 25g-65g of the above-mentioned raw whole grains according to the preset ratio, and add 0.7L-1.2L of drinking water at 100-110°C;

[0043] 2) Pour it into a crushing mixer with a power of 1200-2200W and a rotation speed of 22000-45000 rpm and stir for 200s-300s.

[0044] Preferably, the power is 1600-2000W, and the rotation speed is 2400-2800 rpm.

[0045]The whole grain healthy tea made by this method does not add any additives and preservatives, and is rich in vitamin B group and other elements, plant biochemical elements, soluble plant cellulose and insoluble cellulose, combined with modern technology, using the stirring machine High-speed rotation, wall-breaking extraction technology, extracts all the nutrients of the grain, and makes it into grain tea, which has a delicate taste and is easier ...

Embodiment 1

[0051] 35 parts of peanuts, 30 parts of oats, 20 parts of sesame, 15 parts of flaxseed, 15 parts of buckwheat, 0.7L of water.

[0052] Take 25g of the mixture of peanuts, oats, sesame, linseed and buckwheat mixed according to the above ratio and 0.7L of 100°C water, put it into a pulverizer with a power of 1500W and a speed of 25000 rpm and stir for 200s.

Embodiment 2

[0054] 30 parts of peanuts, 30 parts of oats, 20 parts of sesame seeds, 10 parts of flax seeds, 10 parts of buckwheat, 10 parts of germinated brown rice, 25 parts of corn, 0.7L of water.

[0055] Take the mixture of peanuts, oats, sesame, linseed, buckwheat, germinated brown rice and corn mixed with the above ratio 30g and 0.8L of water at 100°C and put it into a crushing mixer with a power of 1500W and a speed of 22000 rpm and stir for 200s. Can.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com